System Design Considerations

The automatic sprinklers, air compressor, releasing devices,

electric releasing control equipment, fire detection devices,

manual pull stations, and signaling devices which are utilized

with this Reliable Single Interlock Preaction System must be Loss

Prevention Certification Board (LPCB) approved, as applicable.

The system valve and all interconnecting piping must be located

in a readily visible and accessible location and in an area that

can be maintained at a minimum temperature of 40°F (4°C). Note:

Heat tracing is not permitted.

The redundant solenoid valves are operated and supervised by

an electrical releasing/control panel.

System Air Pressure Requirements

When a Reliable Single Interlock Preaction System is utilized,

the sprinkler system piping requires a minimum of 7 psi (0,5

bar) supervisory pneumatic pressure. The Model A Pressure

Maintenance Device, along with an additional air pressure

regulator, are used to maintain the system pneumatic pressure

between 7 and 10 psi (0,5 and 0,7 bar) where a dry nitrogen gas

supply or a clean, dependable, and continuous (24 hours per

day, 7 days per week) compressed air source is available.

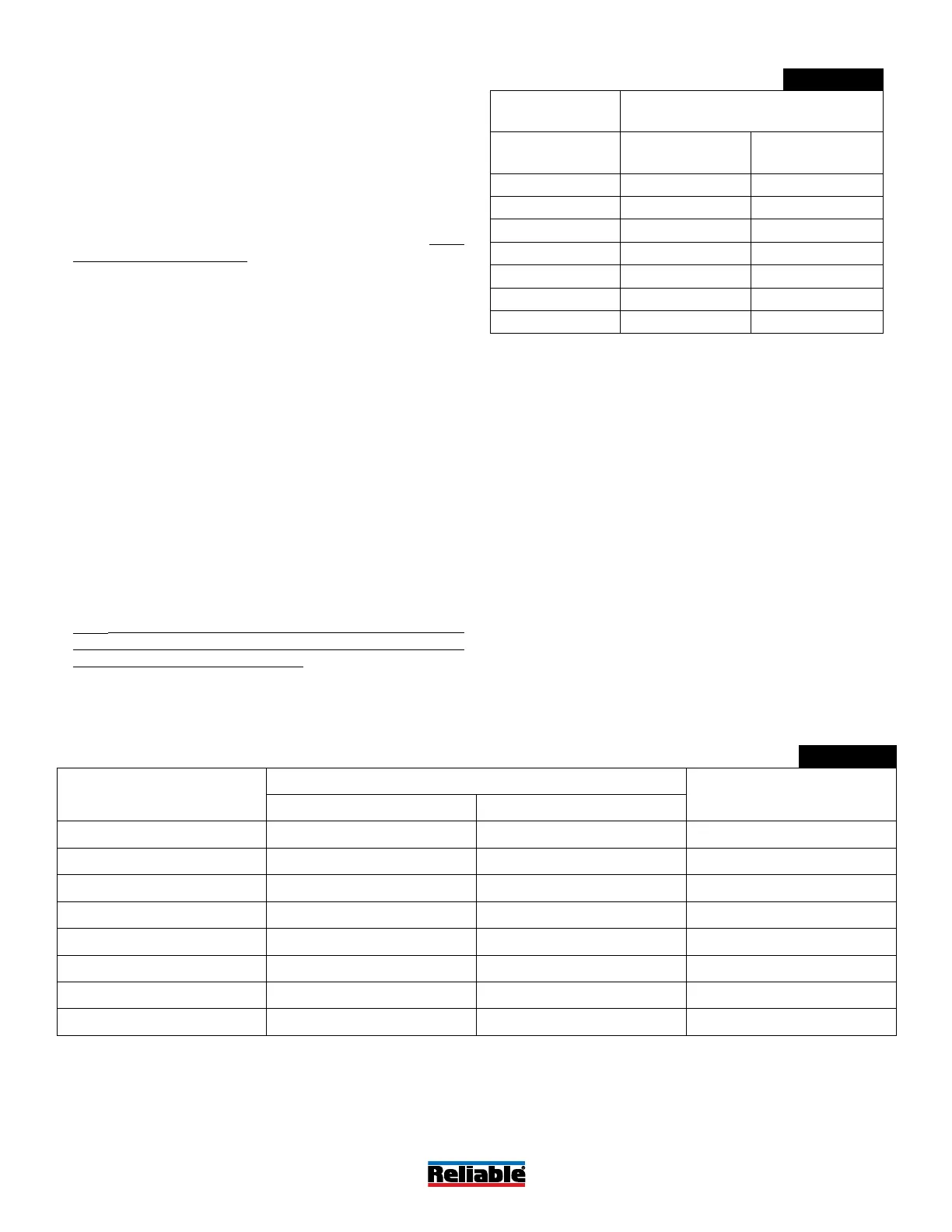

The section of the preaction trim that contains the two redundant

normally-closed solenoid valves, and the supply to the pneumatic

actuator require pneumatic pressure settings per Table C. When

establishing the preaction system for service, refer to Table C

of this bulletin for the correct pneumatic pressure settings for a

corresponding water supply pressure.

Note: During the initial system set-up, a higher pneumatic

pressure may be required in order to properly seat the internal

diaphragm of the pneumatic actuator.

Refer to Reliable Bulletin 251 for instructions on how to modify

these pressure settings.

Bulletin 739

June 2020

Page 4 of 9

www.reliablesprinkler.com

Water Pressure

psi (bar)

Pneumatic Pressure to be Pumped

into Sprinkler System, psi (bar)

Maximum Not Less Than Not More Than

20 (1.4) 10 (0.7) 14 (0.9)

50 (3.4) 12 (0.8) 16 (1.1)

75 (5.2) 13 (0.9) 17 (1.2)

100 (6.9) 15 (1.0) 19 (1.3)

125 (8.6) 16 (1.1) 20 (1.4)

150 (10.3) 17 (1.2) 21 (1.4)

175 (12.1) 18 (1.2) 22 (1.5)

System Pressure

Table C

System Electrical Requirements

All releasing, alarm and detection devices in this Reliable Single

Interlock Preaction System are supervised by the Preaction

Panel Series 1000 MK4. The power supply, the standby

emergency power supply, battery charger, and the rectifier

circuitry are all contained within this panel. For additional and

detailed wiring information, refer to the manufacturer’s literature

included with the Releasing Control Panel.

Note: In order for the solenoid valve to maintain Reliable

warranty it must remain sealed as it came from the factory. If

there are concerns about the valve’s internal components,

immediate replacement is recommended.

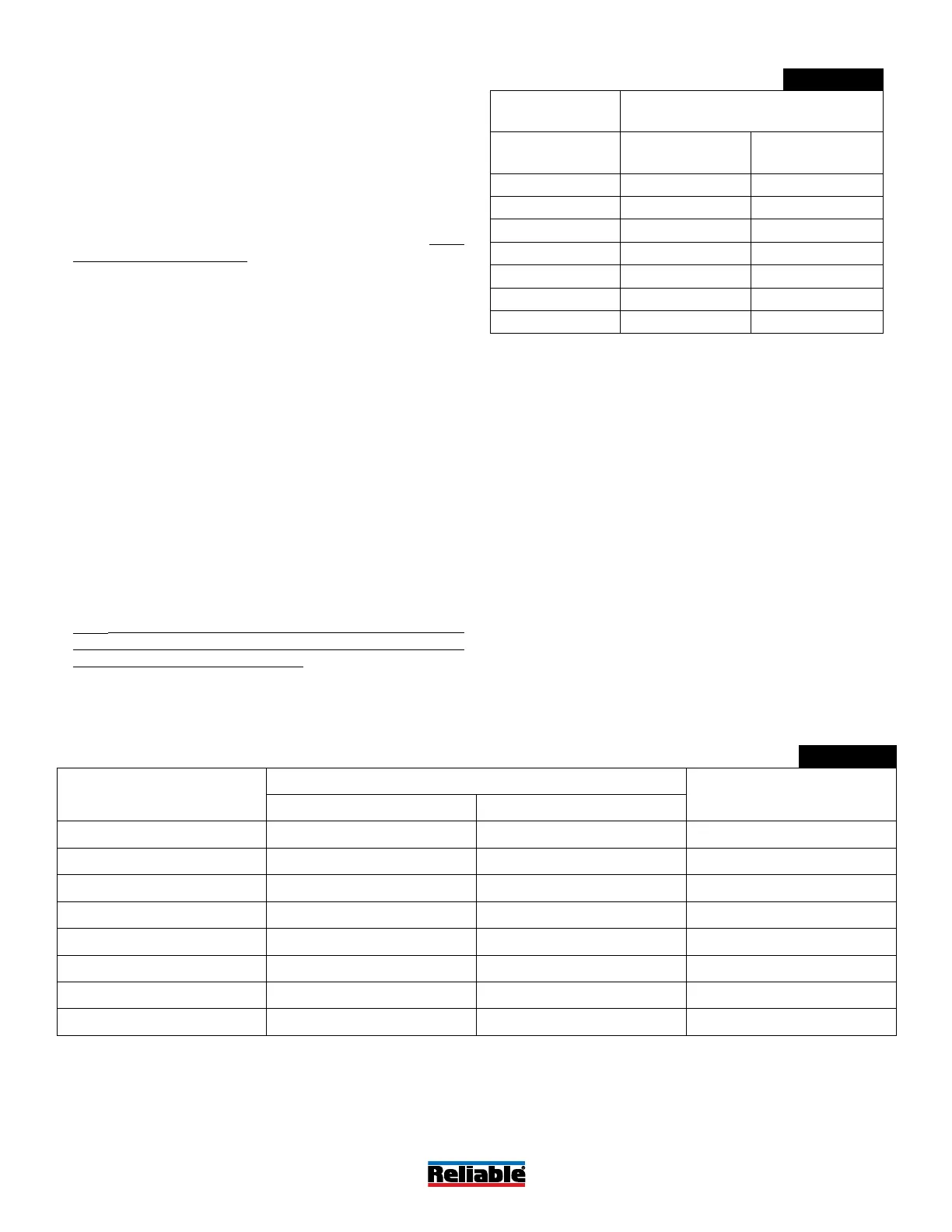

Valve Size:

Equivalent Length:

Cv

C = 120 C = 100

2" (50mm) 4.4 ft (1,3 m) 3.1 ft (1,0 m) 101

2-1/2" (65mm) 6.0 ft (1,8 m) 4.3 ft (1,3 m) 236

76mm 7.7 ft (2,3 m) 5.5 ft (1,7 m) 241

3" (80mm) 12.6 ft (3,8 m) 9.0 ft (2,7 m) 254

4" (100mm) 14 ft (4,3 m) 10 ft (3,0 m) 469

165mm 29.4 ft (9,0 m) 20.9 ft (6,4 m) 886

6" (150mm) 29.4 ft (9,0 m) 20.9 ft (6,4 m) 886

8" (200mm) 53.5 ft (16,3 m) 38.1 ft (11,6 m) 1516

Friction Loss

Table D

Loading...

Loading...