has a limited arc of movement in relation to the distributor body.

Distributor rotation is anti-clockwise when viewed from above.

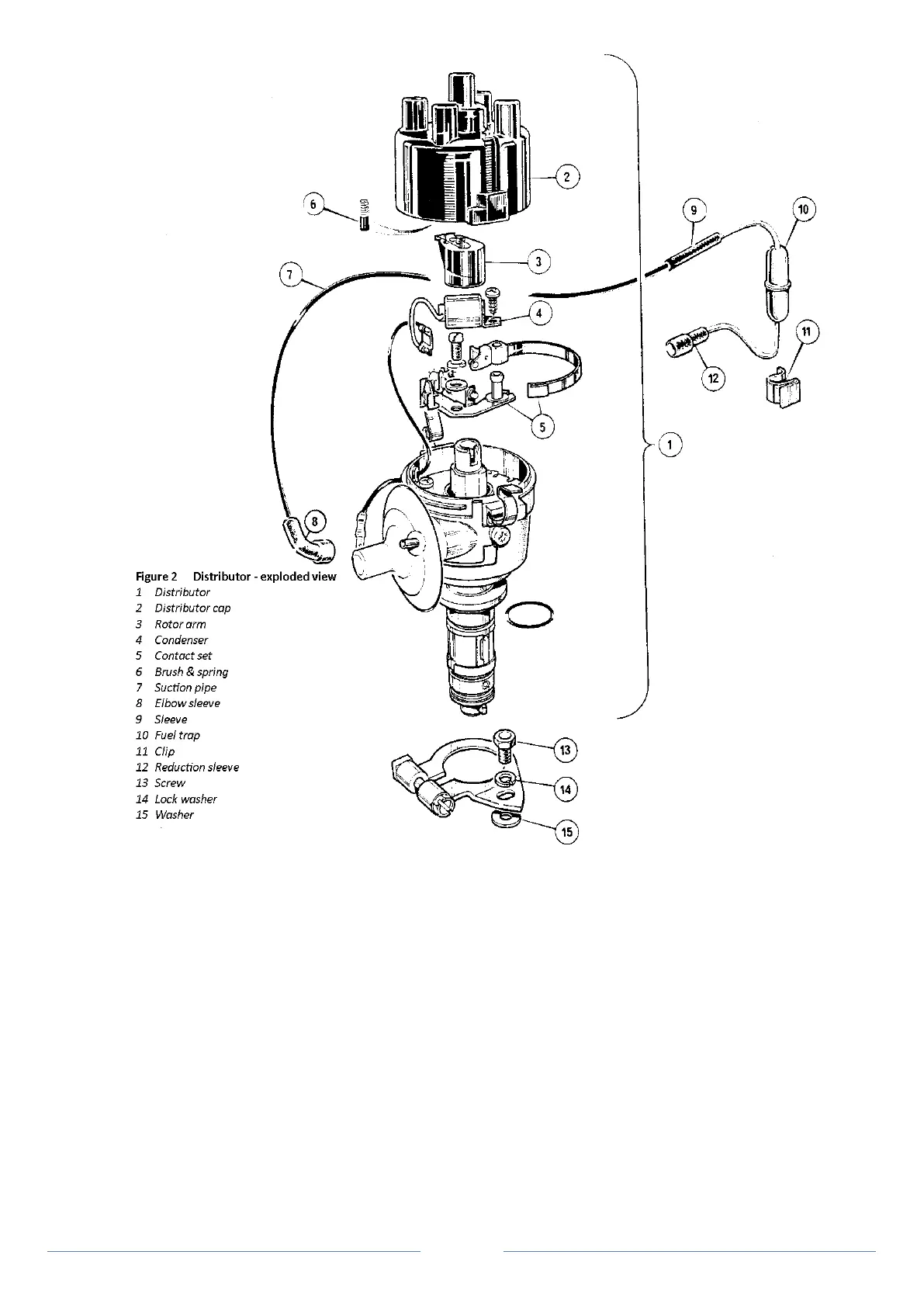

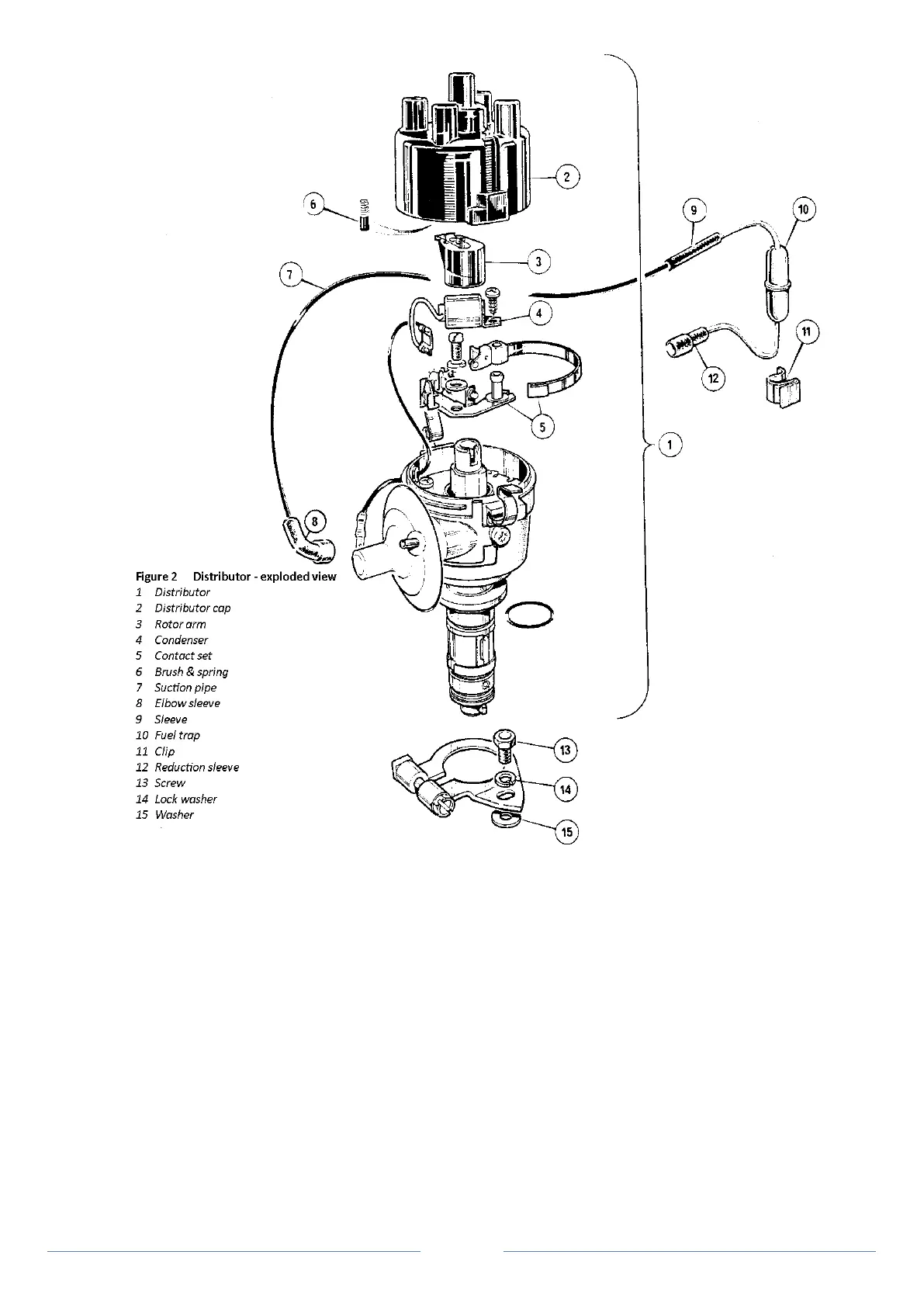

Lubrication of distributor

The cam and contact breaker plate pivots and bushing, when

assembling after overhaul, should be lightly lubricated with Shell

Retinax "A" or equivalent. The governor weights and contact breaker

arm pivot should be lightly oiled every 6,000 miles (10,000 km). To

lubricate the cam spindle, remove the rotor arm and apply two drops

of oil to the felt pad. The felt brush fitted to the contact breaker plate

augments lubrication of the cam. This does not require periodic

lubrication as it is impregnated before fitting. Only a film of engine oil

should be applied to the hollow breaker arm pivot post, ensuring that

none contaminates the distributor points.

Caution: Do not over lubricate any part of the distributor. the

presence of dirt, oil or water on the points, the central carbon brush

or in the contact segments in the distributor cap will cause erratic

running or may even prevent the engine from running at all.

Contact breaker points

To adjust

1. Remove the distributor cap and rotor arm.

2. Turn the engine so that the heel of the contact breaker is

on the highest point of the cam. (it may be necessary to remove the

spark plugs to eliminate the resistance caused by engine

compression).

3. Slacken the slot headed screw (Figure 3)in the contact plate

and adjust until the gap is 0.38mm (0.015 in). The gap is measured

with a suitable feeler gauge and pressure should be applied to the

points, with the feeler gauge inserted between them whilst the screw

is tightened.

4. re-tighten the screw and make a further check with the

feeler gauge in case tightening has altered the setting.

5. Refit the rotor arm with the slot and lug in line. Press the

rotor firmly in to place on the spindle.

Note: When the rotor arm is fitted to the spindle the lower face does

not abut the cam

Loading...

Loading...