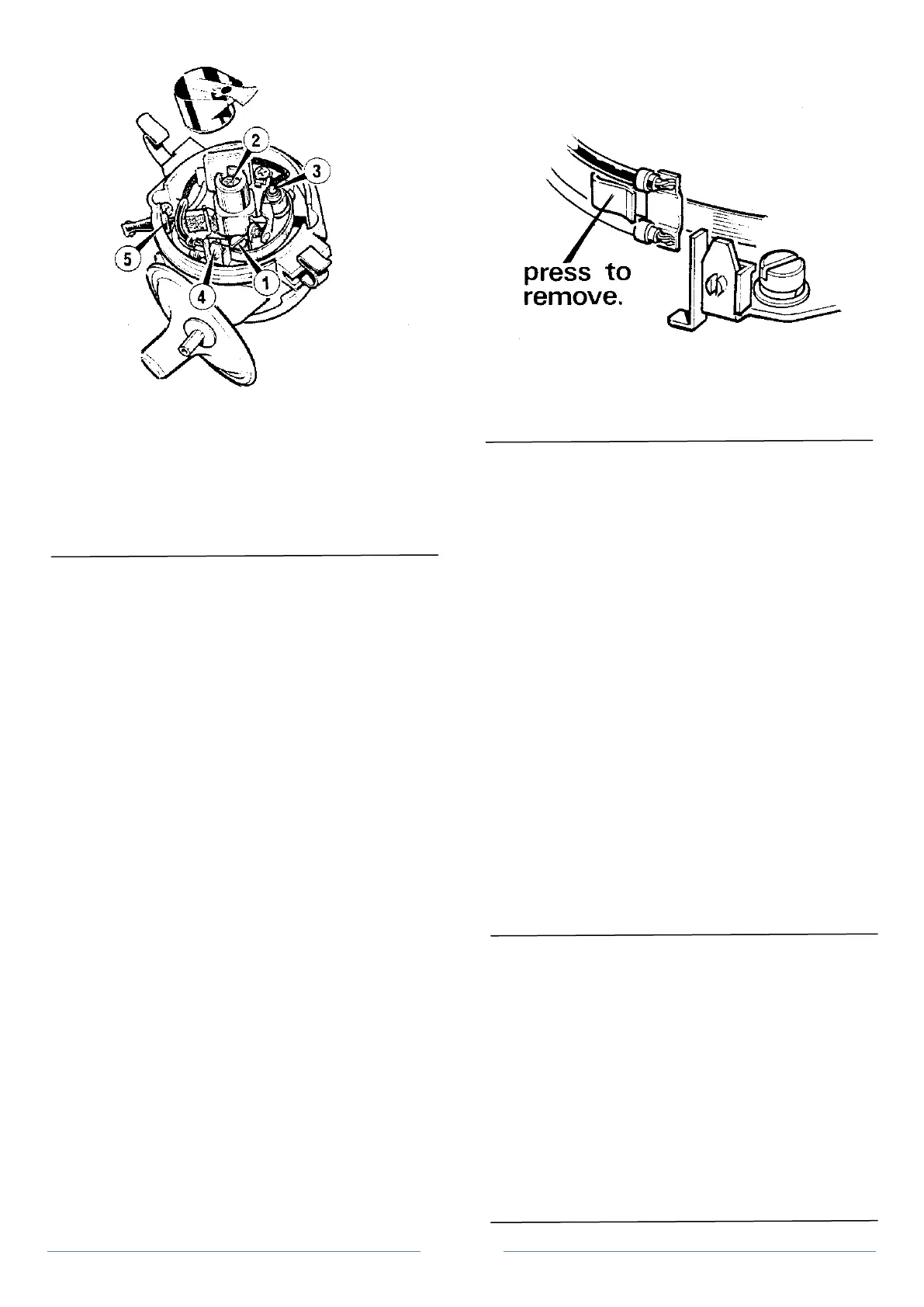

Figure 3 Contact breaker adjustment

1. Locking/adjustment screw

2. Cam spindle lubrication pad

3. Breaker arm pivot point

4. Terminal post

5. Low tension lead

Operation 1 Removal & examination of contact breaker

points

1. Remove the distributor cap and rotor arm.

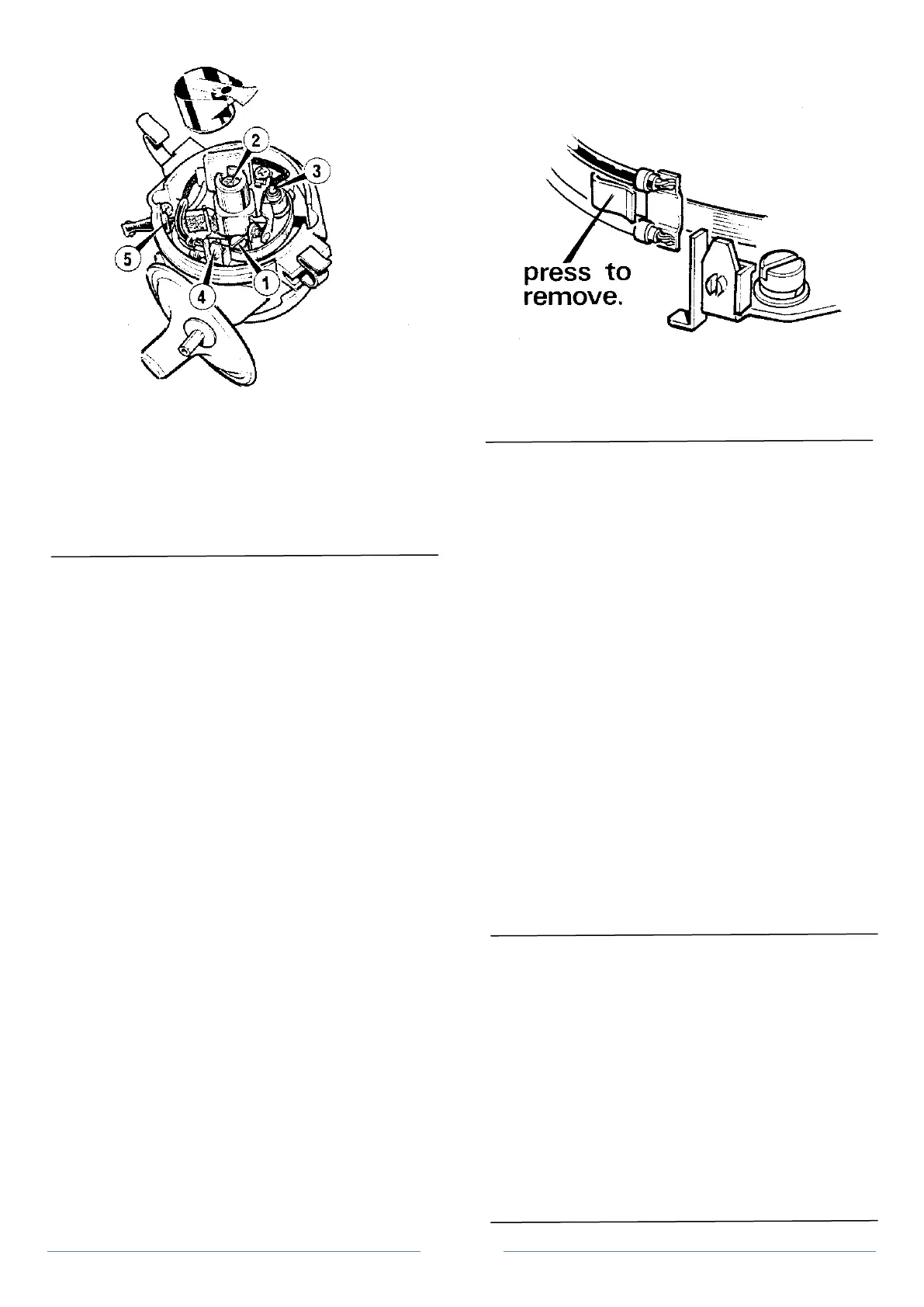

2. Press the terminal end of the moving contact spring

towards the cam (Figure 4). this will disengage the spring from the

insulating piece attached to the terminal post. The capacitor lead and

the low tension fly-lead can then be detached from the folded end of

the spring. remove the slotted screw securing the fixed contact and

lift the assembly from the base plate.

3. Check the condition of the points for signs of wear or

burning on the contacts. If this is apparent, the complete assembly

will need replacing. Contacts showing a greyish colour and only

slightly pitted can be smoothed with a fine emery stone and then

thoroughly cleaned with carbon tetrachloride.

To replace

1. When refitting or replacing a contact breaker set, it is

important to note that the capacitor and low tension fly-lead

connecting terminal in the folded end of the moving contact spring

has the cable clips facing outward. Otherwise the lower clip may foul

the fixed contact plate short circuiting the contact breaker. (Figure 4)

2. Replace the slotted screw and adjust the contact breaker

points as previously described.

Note: If a new contact set is fitted, set the contact gap to 0.40 to 0.45

mm (0.016 to 0.019 in) to allow for initial bedding in of the plastic

heel.

3. Replace the rotor arm and distributor cap.

Operation 2 Condenser - removal & replacement

The condenser is fitted in parallel with the contact breaker points. A

short circuit in the condenser will cause ignition failure as the contact

points will no longer interrupt the low tension circuit. In such cases

the condenser will need replacing.

An open circuit, however, cannot be readily checked without the use

of specialised equipment such as a diagnostic test set. The usual

symptoms of this are excessive arcing and burning of the contact

Figure 4 Correct replacement of points

breaker points and difficult starting.

To remove the condenser

1. Remove the distributor cap and rotor arm.

2. Remove the contact breaker assembly

3. Remove the cross head screw and lift the condenser from

the base plate.

4. The condenser, condenser lead and low tension fly-lead are

a complete assembly. The fly-lead, complete with grommet and

insulated "lucar" terminal should be withdrawn through the hole in

the distributor body (Figure 2).

5. replace in reverse order taking care that there is no

possibility of a short circuit between the condenser lead terminal and

the contact breaker plate.

Note: Dismantling of the complete distributor is not recommended as

only the cap, rotor arm, condenser and lead assembly and contact

breaker assembly are available as spares.

Operation 3 To remove the distributor from the engine

1. Disconnect the spark plug leads and "King" lead to the coil.

2. Remove the low tension fly-lead from the coil.

3. Unscrew the single colt and washer securing the distributor

clamp to the block, and withdraw the distributor. Do not disturb the

clamping bolt securing the clamp to the distributor body.

4. Replace in reverse order.

Distributor specification

Type Lucas 45D4 single pair

contact breaker points

Drive Dog-gear from camshaft

Firing order 1, 3, 4, 2.

Ignition advance Vacuum

Static timing 10°BTDC

Rotation Anti-clockwise (from above)

Firing angle 0-90°- 180°- 270°+/- 1°

Dwell angle 51° +/- 5°

Contact breaker gap 0.38 mm (0.015 in)

0.40-0.45 mm (0.016-0.018

in) for new contact set

Contact spring loading 522-880 gf (18-24 ozf)

Condenser 0.18 to 0.25 microfarads

Loading...

Loading...