Wheels

and Tyres

De

sc

ription

The wheels

are

of the pressed steel disc type

and are fitted

with

polished aluminium centre

caps which spring over buttons on the

wheel.

Cross ply

tubeless tyres

are

fitted to all Robin

models.

Tyre pressures

Section M

1

Tyre pressures should

be

checked before a run

when the tyres are

cold. During use the pressure

will

increase and the additional pressure should

not

be rele

ased

since in determining the tyre

pressure this increase has been taken into

account. Under inflation can also result in

damage to the

walls and the tread itself due to

excessive flexing.

1108

Cl

ose

attention to tyre inflation and the

mechanical condition

of

the vehicle

will

not

always prevent uneven tyre wear.

It

is, therefore,

recommended that the front tyre

is interchanged

with

the rear

ty

r

es,

bringing the spare wheel

into

use.

N

ote

:

If

the vehicle is fitted w

it

h cast alloy

wheels on the rear they cannot be interchanged

with

the front pressed steel wheel.

On

no

account

must

radia

l

tyres

be

fitted

.

Jack

ing positions

Before changing a wheel, or carrying out any

servicing operation, ensure the vehicle is on

level

ground,

with

the handbrake applied and

the wheels suitably blocked.

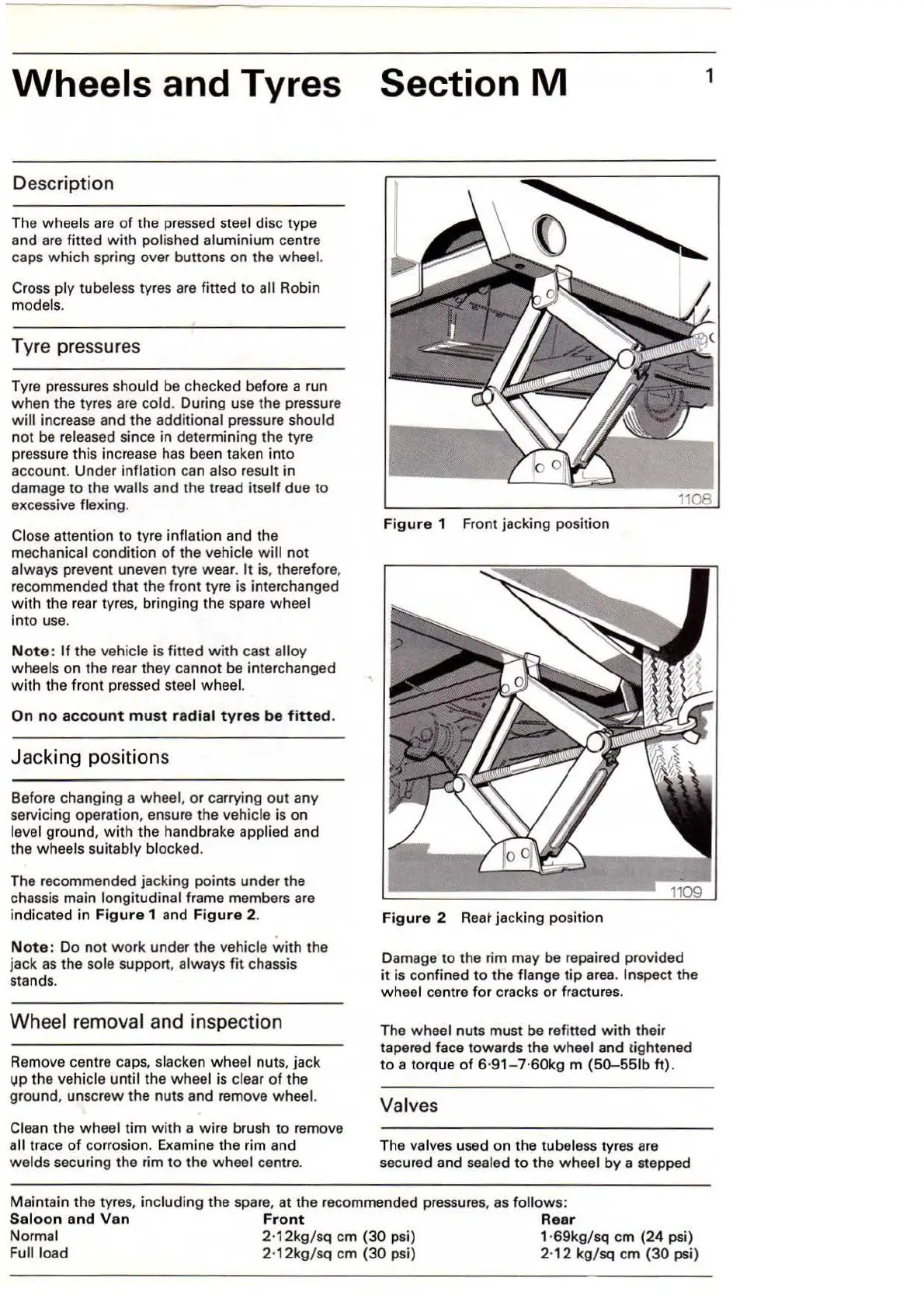

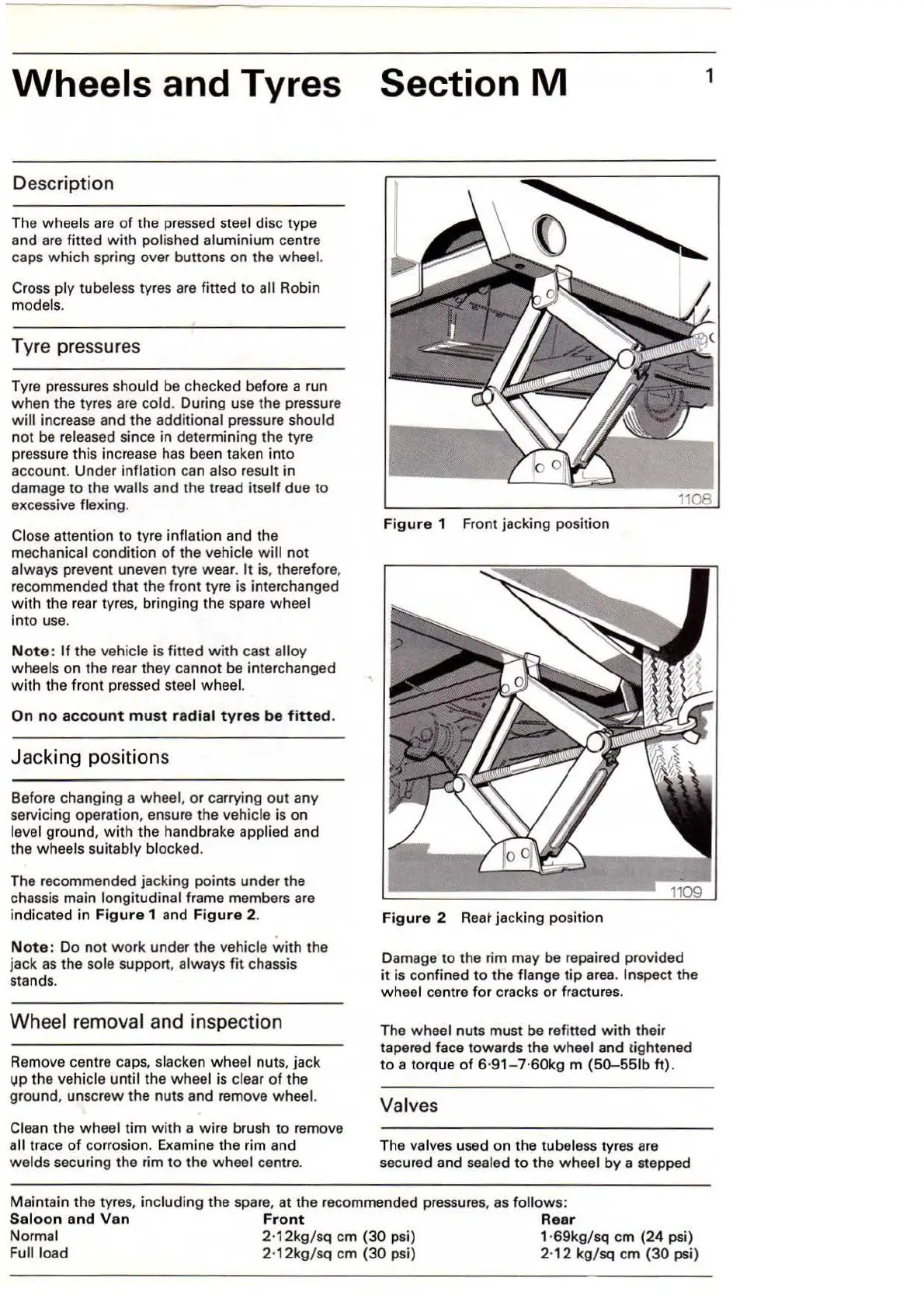

The recommended jacking points under the

chassis main longitudinal frame members

are

indicated in

Figure

1 and

Figure

2.

N

ote

: Do not

work

under the vehicle with the

jack

as

the sole support, always

fit

chassis

stands.

Wheel removal and inspection

Remove centre caps, slacken wheel nuts, jack

VP

the vehicle unt

il

the wheel is clear of the

ground, unscrew the nuts and remove wheel.

Clean

the wheel tim with a

wi

re

brush to remove

all trace

of

corrosion. Examine the rim and

welds securing the rim

to

the wheel centre.

Figure

1 Front jacking position

Fig

ur

e 2

Re

ar

jacking position

Damage to the rim may be repaired provided

it

is confined to the flange

tip

area.

Inspect the

wheel centre for cracks or fractu

res

.

The wheel nuts must be refitted

with

their

tapered face towards the wheel and

tightened

to

a torque

of

6·

91-7·60kg

m (50-551b ft).

Valves

Th

e valves

us

ed on the tubel

ess

tyres are

secured and sealed

to th

e wheel by a stepped

Maintain the

tyr

es,

including the

spa

r

e,

at the recommended pressures,

as

follow

s:

Sal

oo

n and Van

Fr

ont Rear

Normal

2·12kg/sq

em

(30 psi) 1·69kg/sq

em

(24 psi)

Full load 2·12kg

/sq

em

(30

psi) 2·

12

kg/sq

em (30 psi)

Loading...

Loading...