11/6/2012 19 Retsch GmbH 0002

Adjusting the Scraper to the Mortar

When the machine is delivered or when a scraper is

re-ordered, it may be necessary to regrind scraper A.

This depends on the shape of the mortar M or the

wear on it.

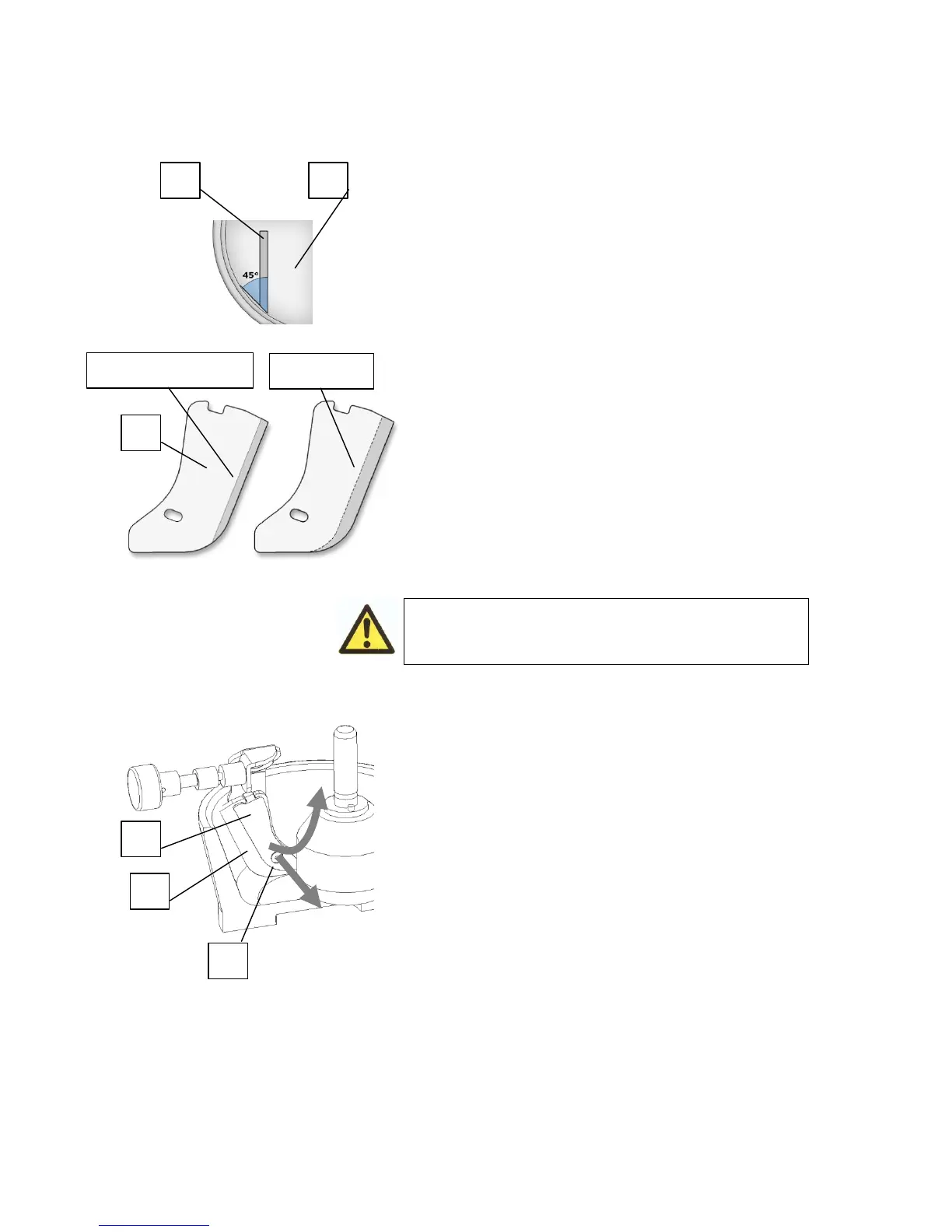

Fig.7.1

Regrinding is necessary in the following cases:

• when the machine is supplied without a mortar or

grinding set

• when a scraper or mortar is reordered

The scraper was chamfered slightly in the factory in

order to make regrinding easier. The grinding angle

should be 45° and depend on the shape of the

mortar.

Fig.7.1 und Fig.7.2

You can use a belt sander, a grindstone or sandpaper

to do the grinding.

The scraper can become sharp-edged as a result of

sanding and wear during grinding operations. During

cleaning in particular there is a risk of injury.

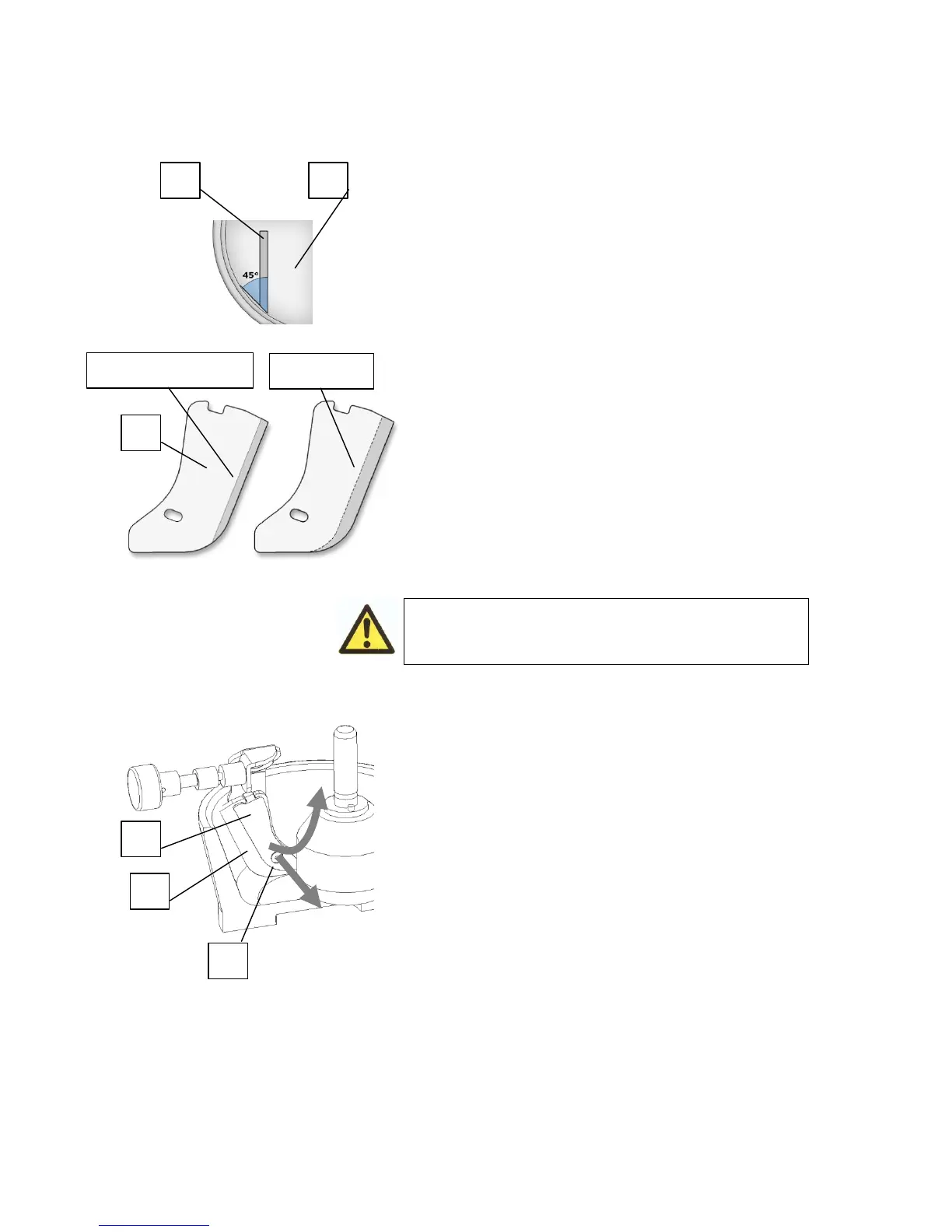

Installing / replacing the scraper

• Open the cover M.

• Flip the cover to the back.

• Loosen the screw Y with the supplied screwdriver.

• Remove the retaining screw Y.

• Swing out the mounting bracket.

• Remove the scraper.

• Insert the new scraper.

• Hook the mounting bracket Z again.

• Turn the screw Y loose.

• The scraper can be adjusted by its slot slightly

forward or backward.

• Slide the scraper backwards.

• Tighten the screw. Fig.9

• Close the cover.

• Check visually or by sample material if the scraper

is applied accurate on the mortar.

Loading...

Loading...