workpiece at all times for proper cutting If the teeth of t

Blade are so far apart that they straddle the work, sever

damage to the workpiece and to the Made can result .

G.CHANGING BLADE:

Raise saw head to vertical position and open the blade

guards. Loosen tension screw knob sufficiently to allow

the saw blade to slip off the wheels. Install the new blad

with teeth slanting toward

he

e

e

the motor as follows:

blade upward with the right hand

m pulley and place is at

n

st

inger as guides.

(

H.

(1) (

(a)

) The position of the vise when tightened.

) The position of the vise when loosened.

ened.

as follows:

) Rise the arm 2” above the workpiece, close the

he arm 2” above the

ble. Move the vise

alf

e jaw bracket against the

w

h

h ce in

3) , hold the

) to a 90 degree

(c pened). Remove workpiece.

Whe

the e (a) to loosen and adjust workpiece

ndle to

(b)

e

e by turning rectangular handle only.

ten the

ar vise to the threaded hole position. (E)

). Set the scale to the desired angle.

)

11. BLADE GUIDE BEARING ADJUSTMENT

ATTENTION: This is the most important adjustment on

your saw. It is impossible to get satisfactory work from

your saw if the blade guides are not properly adjusted.

ting Band

(1). Place the blade in between each of the guide

bearings.

(2). Slip the blade around the motor pulley (bottom) with

the left hand and hold inposition.

(3). Hold the blade taut against the motor pulley by

pulling the

which is placed at the top of the Made.

(4). Remove left hand from botto

the top aide of the Made to continue the application o

the upward pull on theblade.

(5). Remove right hand from blade and adju

the position of the top pulley to permit left

hand to slip the blade around the pulley using

the thumb, index and little f

(6). Adjust the blade tension knob clockwise

until it is just right enough so no blade

slippage occurs. Do not tighten excessively.

7). Replace the blade guards.

(8). Place 2-3 drops of oil on the blade.

USAGE OF THE OUICK VISE:

2)

(b)

(3)

(1

(2

(Completely opened).

(3) The position of the vise when loos

( Half opened).

TRU-LOCK VISE SYSTEM

INSTRUCTIONS

To operate, proceed

1

cylinder valve to maintain t

workpiece.

2) Put your workpiece on the ta

handle (a) upwards to an angle of 45 degree (a-H

opened) to loosen the vise.

Move the vis

orkpiece by turning the rectangular

andle (b) . Push down on the vise

andle (a) to lock the workpie

position.

To loosen the workpiece from the vise

workpiece and lift the vise handle (a

position

ompletely o

CONTINUED CUTTING

n you need to cut a workpiece many times, just raise

vise handl

position. Then push down on the same ha

tighten.

You can also push the vise handle (a) down first, then

tightening the vise by turning the rectangular handle

clockwise. After finishing the cut, you can loosen th

workpiec

This Tru-Lock Vise System has a 3mm tightening travel

when the rectangular handle is completely opened.

There is only a 1mm tightening travel necessary for

normal metal materials. The operator can tigh

workpiece by pushing down the vise handle (a) with a

certain amount of pressure depending on hardness of

workpiece.

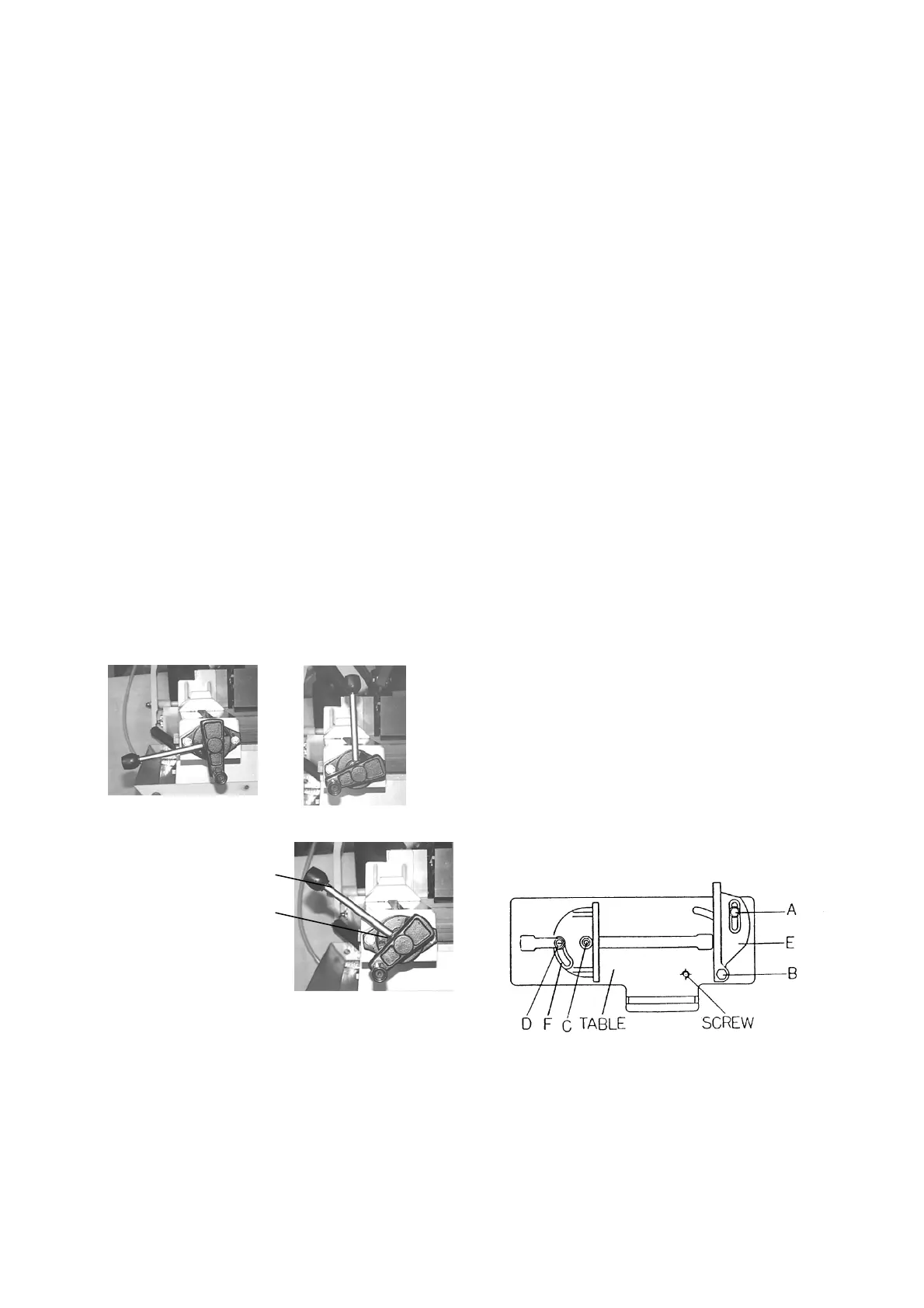

I. QUICK VISE ADJUSTMENT FOR ANGLE CUT:

(1). Loosen the A. B. C. D. Screw.

(2). Adjust re

(3

(4). Adjust the front vise (F) to parallel the rear vise(E

(5). Tighten the A. B. C. D. Screw.

The blade guide bearings on your metal. Cut

Saw are adjusted and power tested with several test cuts

before leaving the factory to insure proper setting The

-9-

Loading...

Loading...