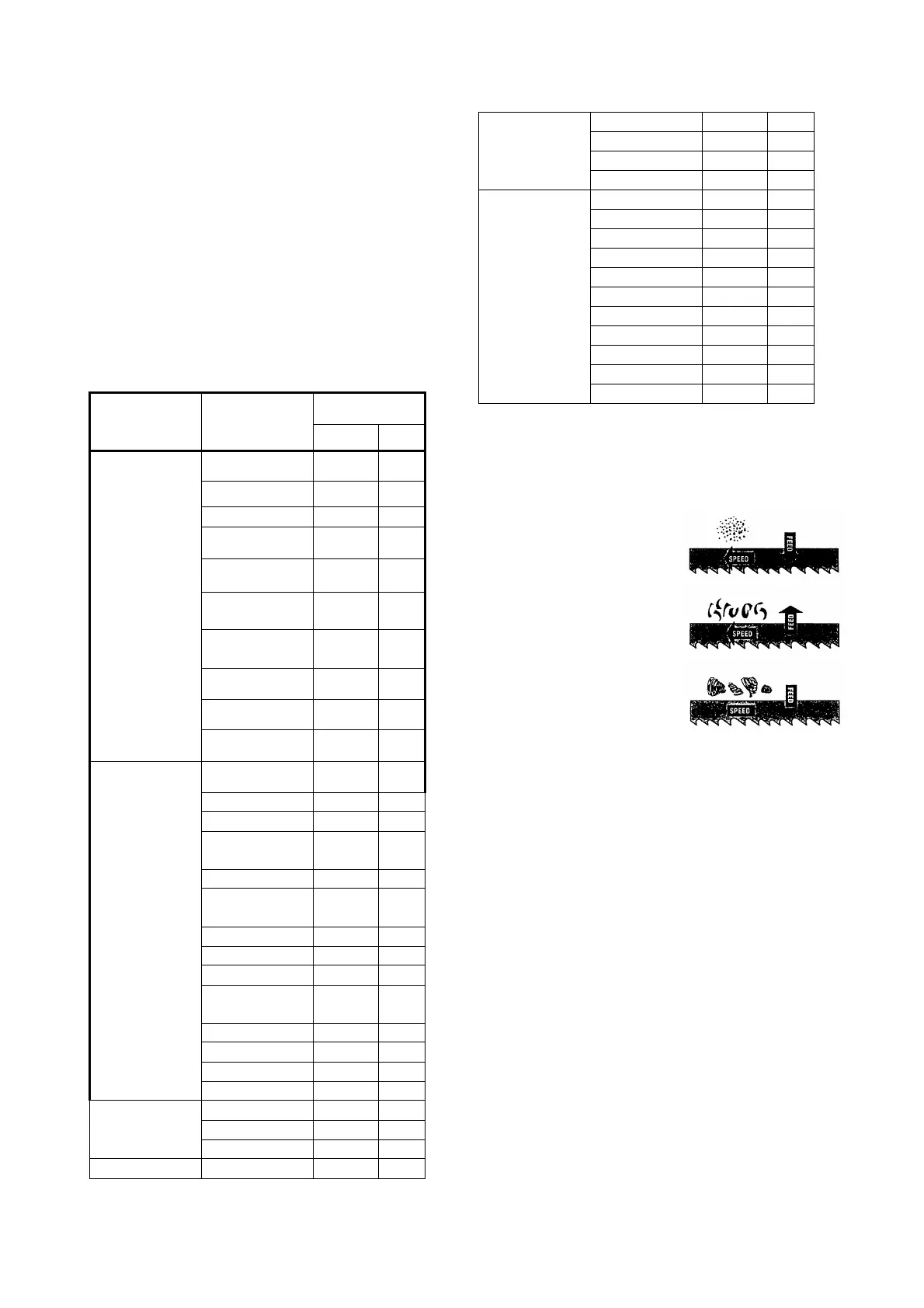

8. BI-METAL SPEEDS AND FEEDS

These figures are a guide to cutting 4"(100mm) material

(with a 314 Vari-Tooth) when using a cutting fluid.

Increase Band Speed: 15% When cutting

1/4"(6.4mm) material (l0/l4 Vari-Tooth)

12% When cutting 3/4"(19

mm) material (6/10 Vari-Tooth)

10% When cutting

1-1/4"(32 mm) material(5/8 Vari-Tooth)

5% When cutting 2-1/2"

(64 mm) material(4/6 Vari-Tooth)

Decrease Band Speed: 12% When cutting 8"(200mm)

material(2/3 Vari-Tooth)

BAND SPEED

MATERIAL ALLOY

ASTM NO.

FT./MIN M/MIN

173,932 314 96

330,365 284 87

623,624 264 81

230,260,272 244 74

280,264,632,655 244 74

101,102,110,122

,172

234 71

1751,182,220,51

0

234 71

625,706,715,934 234 71

630 229 70

Copper

Alloy

811 214 65

1117 339 103

1137 289 88

1141,1144 279 85

1141 HI

STRESS

279 85

1030 329 100

1008,1015,1020,

1025

319 97

1035 309 94

1018,1021,1022 299 91

1026,1513 299 91

A36(SHAPES),1

040

269 82

1042,1541 249 76

1044,1045 219 67

1060 199 61

Carbon

Steel

1095 184 56

8615,8620,8622 239 73

8640, 199 61

Ni-Cr-Mo

Alloy Steel

E9310 174 53

Tool Steel A-6 199 61

A-2 179 55

A-10 159 49

D-2 90 27

H-11,H-12 H-13 189 58

420 189 58

430 149 46

410,502 140 43

414 115 35

431 95 29

440C 80 24

304,324 120 36

304L 115 35

347 110 33

316,316L 100 30

Stainless

Steel

416 189 58

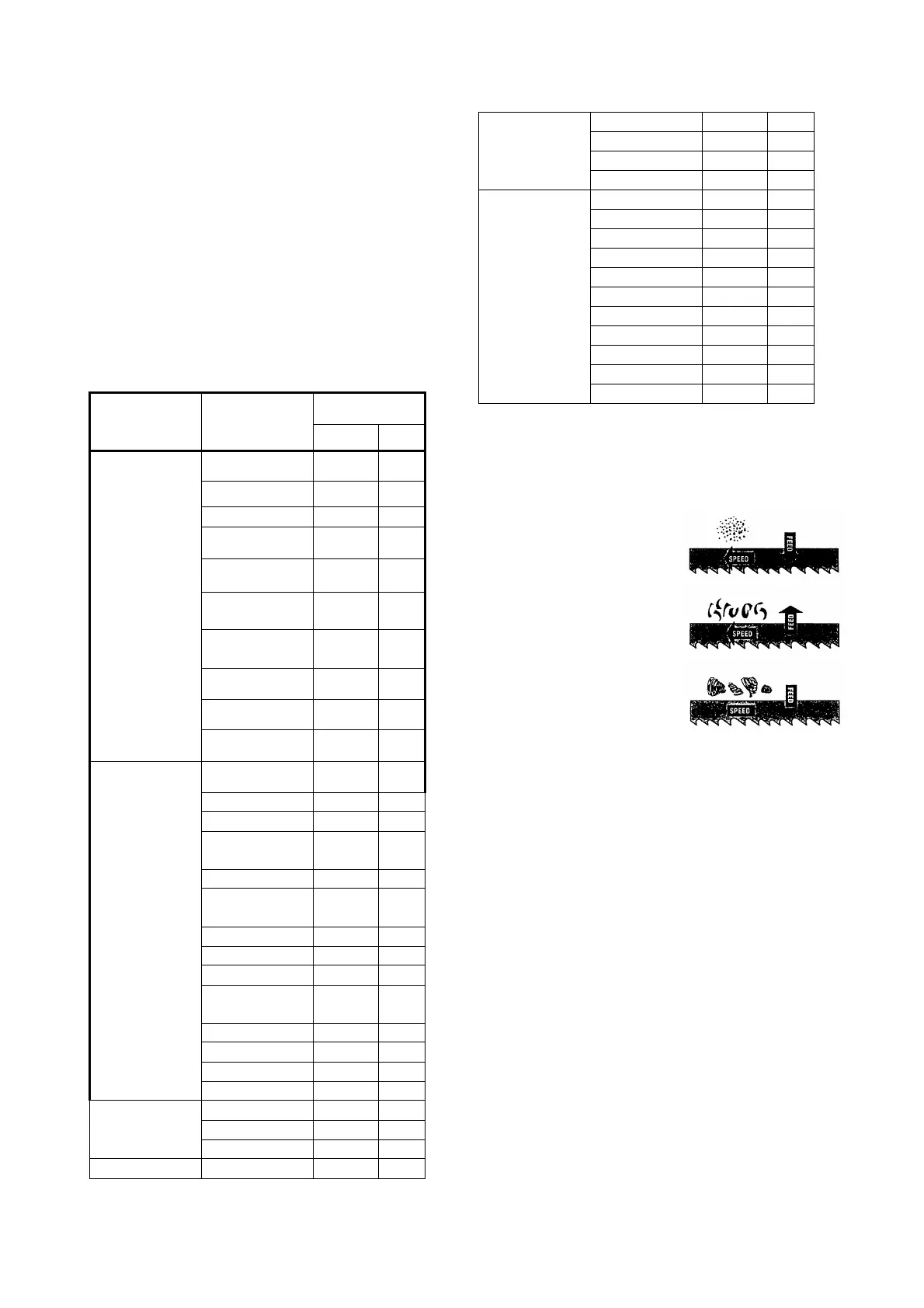

TELLTALE CHIPS

Chips are the best indicator of correct feed force. Monitor

chip information and adjust feed accordingly.

Thin or powdered chips – increase feed rate or reduce

band speed.

Burned heavy

chips – reduce feed rate

and/or band speed.

Curly silvery and warm chips –

optimum feed rate and band

speed.

9. ASSEMBLY

A 3/4 HP, motor, split phase or capacitor-start it

recommended for best economical performance.

Counterclockwise rotation is required. Note that rotation

can be reversed by ollowing directions

given on terminal or nameplate.

(1). Assemble the motor Mounting plate to the head using

the long bolt Note that the flat side of the plate faces up.

(2). Assemble the guard plate to the head using the

screw and Lock Washer and the Carriage Bolt Washer

and Wing Nut are used to secure the motor mounting

plate to the Guard plate through the slotted hole in the

Guard plate. These components also serve to position

and lock the motor in place for proper speed/ belt

adjustment.

(3). Place the spacer over the long Bolt and secure it wit

the nut .

(4). Secure the Motor to the Motor Mounting plate with

the four bolts and nuts. Note, that the motor shaft is

placed through the large opening in the Guard plate and

must be pareallel with the drive Shaft.

(5). Assemble the Motor Pulley, the smaller of the two

provided, to the motor shaft Note, the larger diameter

must be closest to the motor.

-6-

Loading...

Loading...