35

Field wiring must comply with the National Electric Code

#%#IN#ANADAANDANYAPPLICABLELOCALCODE

Power Wiring

It is important that proper electrical power from a commercial

utility is available at the condensing unit contactor. Voltage

ranges for operation.

Install a branch circuit disconnect within sight of the unit

ANDOFADEQUATESIZETOHANDLETHESTARTINGCURRENT

Power wiring must be run in a rain-tight conduit. Conduit

must be run through the connector panel below the access

cover and attached to the bottom of the control box.

Connect power wiring to contactor located in outdoor

CONDENSING UNIT ELECTRICAL BOX 3EE WIRING DIAGRAM

ATTACHEDTOUNITACCESSPANEL

Check all electrical connections, including factory wiring

within the unit and make sure all connections are tight.

DO NOT connect aluminum field wire to the contactor

terminals.

Electrical Wiring

Electrical Wiring

Grounding

A grounding lug is provided near the contactor for a ground

wire.

WARNING: The unit must be permanently

grounded. Failure to do so can cause electrical shock

resulting in severe personal injury or death.

Control Wiring

If the low voltage control wiring is run in conduit with

the power supply, Class I insulation is required. Class II

insulation is required if run separate. Low voltage wiring

may be run through the insulated bushing provided in

THEHOLEINTHEBASEPANELUPTOANDATTACHEDTOTHE

pigtails from the bottom of the control box. Conduit can be

run to the base panel if desired by removing the insulated

bushing.

A thermostat and a 24 volt, 40 VA minimum transformer

are required for the control circuit of the condensing unit.

The furnace or the air handler transformer may be used if

sufficient. See the wiring diagram for reference. Use Table

TOSIZETHEVOLTCONTROLWIRING

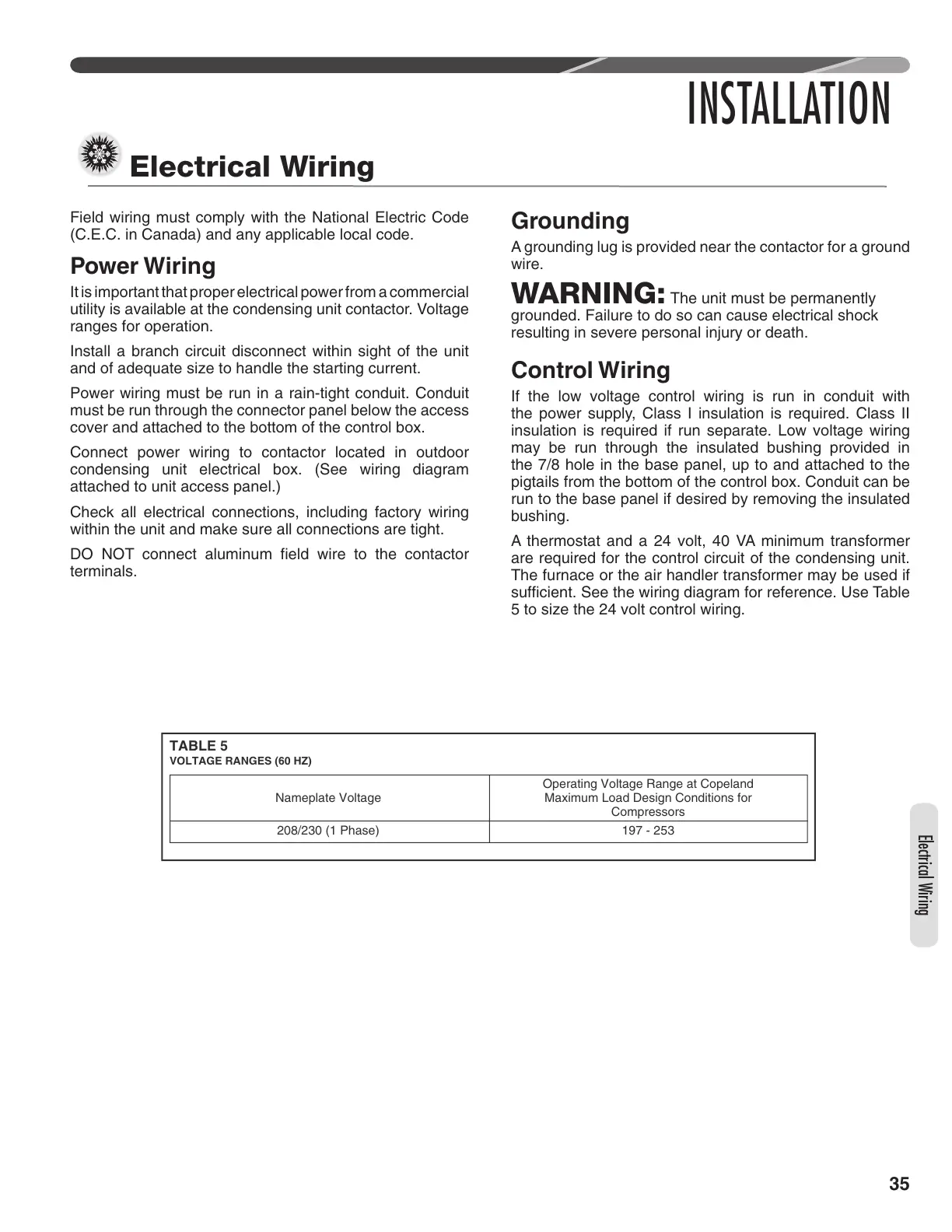

TABLE 5

VOLTAGE RANGES (60 HZ)

Operating Voltage Range at Copeland

Nameplate Voltage Maximum Load Design Conditions for

Compressors

208/230 (1 Phase) 197 - 253

Loading...

Loading...