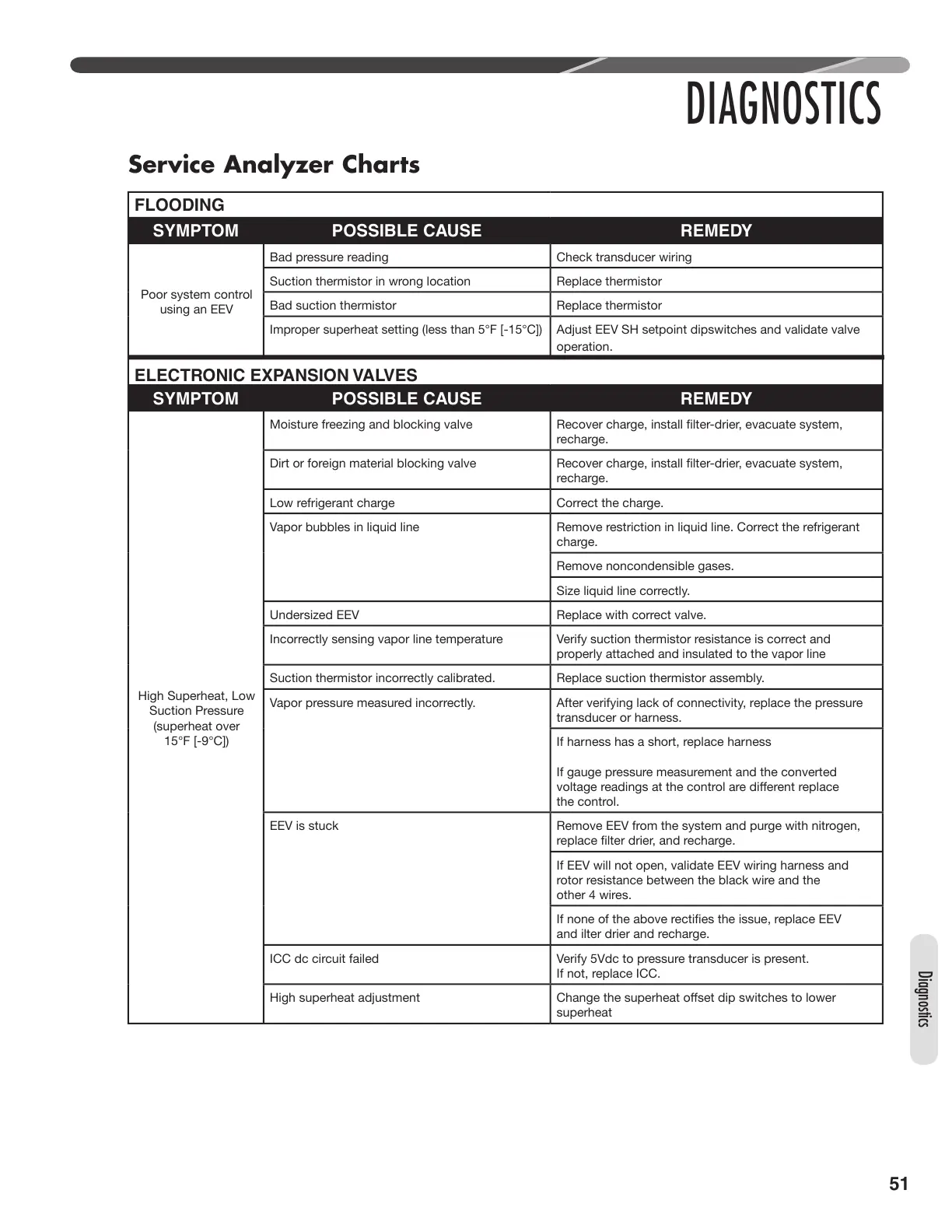

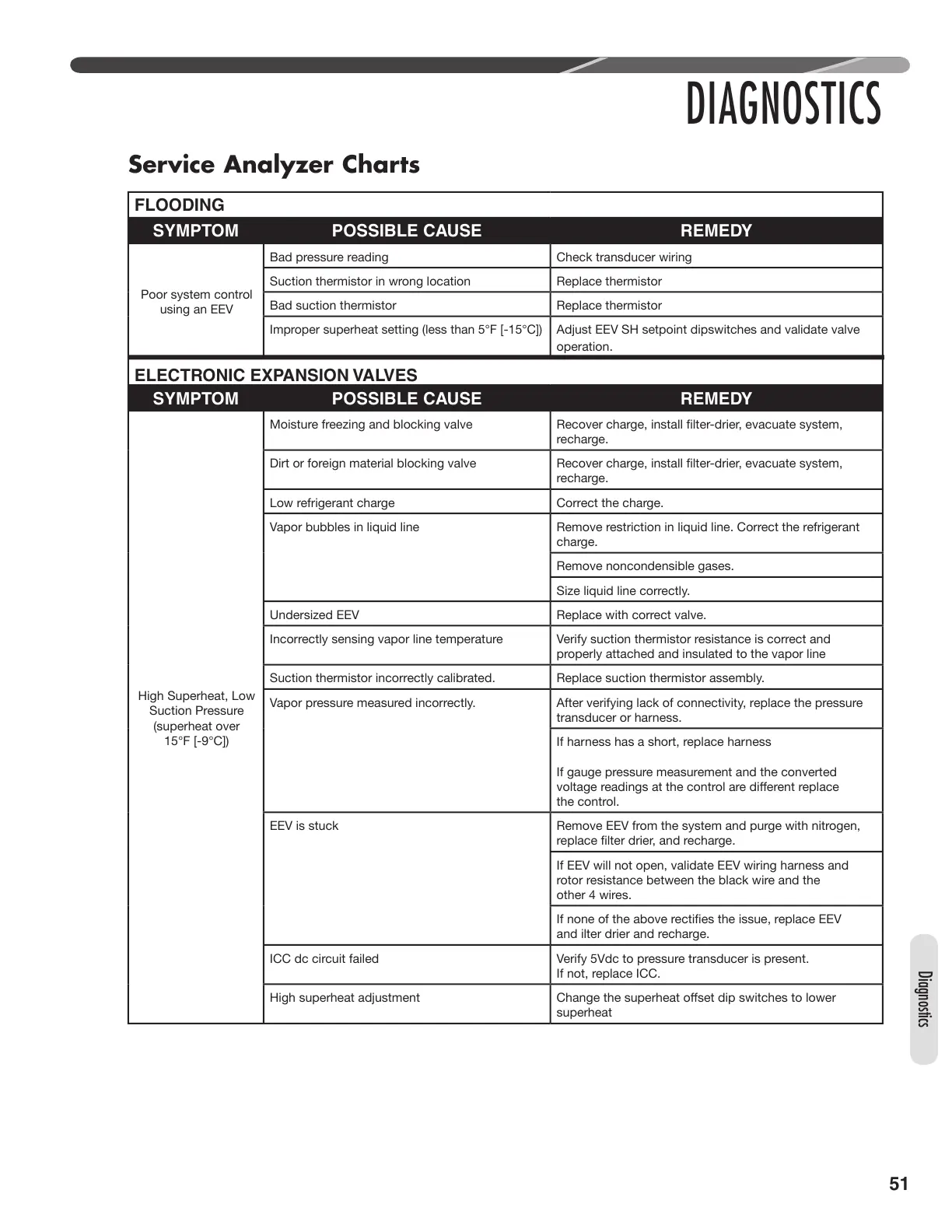

Service Analyzer Charts

FLOODING

SYMPTOM POSSIBLE CAUSE REMEDY

Poor system control

using an EEV

Bad pressure reading Check transducer wiring

Suction thermistor in wrong location Replace thermistor

Bad suction thermistor Replace thermistor

Improper superheat setting less than 5 [-15]

Adjust EEV SH setpoint dipswitches and validate valve

operation.

ELECTRONIC EXPANSION VALVES

SYMPTOM POSSIBLE CAUSE REMEDY

High Superheat, Low

Suction Pressure

(superheat over

15 [-]

Moisture freezing and blocking valve ecover charge, install lter-drier, evacuate system,

recharge.

Dirt or foreign material blocking valve ecover charge, install lter-drier, evacuate system,

recharge.

Low refrigerant charge Correct the charge.

Vapor bubbles in liquid line Remove restriction in liquid line. Correct the refrigerant

charge.

Remove noncondensible gases.

Size liquid line correctly.

Undersized EEV Replace with correct valve.

Incorrectly sensing vapor line temperature Verify suction thermistor resistance is correct and

properly attached and insulated to the vapor line

Suction thermistor incorrectly calibrated. Replace suction thermistor assembly.

Vapor pressure measured incorrectly. After verifying lack of connectivity, replace the pressure

transducer or harness.

If harness has a short, replace harness

If gauge pressure measurement and the converted

voltage readings at the control are dierent replace

the control.

EEV is stuck Remove EEV from the system and purge with nitrogen,

replace lter drier, and recharge.

If EEV will not open, validate EEV wiring harness and

rotor resistance between the black wire and the

other 4 wires.

If none of the above recties the issue, replace

and ilter drier and recharge.

ICC dc circuit failed Verify 5Vdc to pressure transducer is present.

If not, replace ICC.

High superheat adjustment hange the superheat oset dip switches to lower

superheat

Diagnostics

Loading...

Loading...