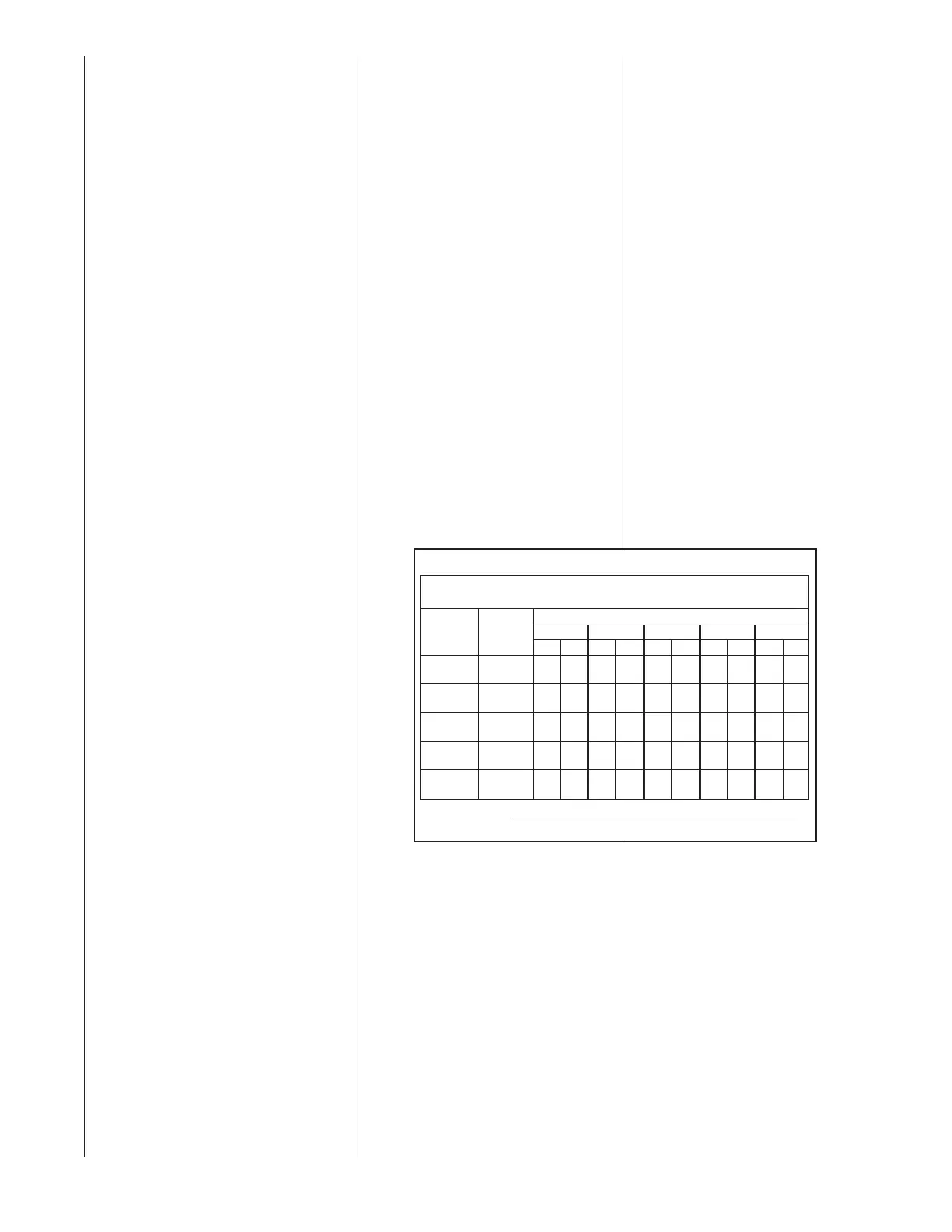

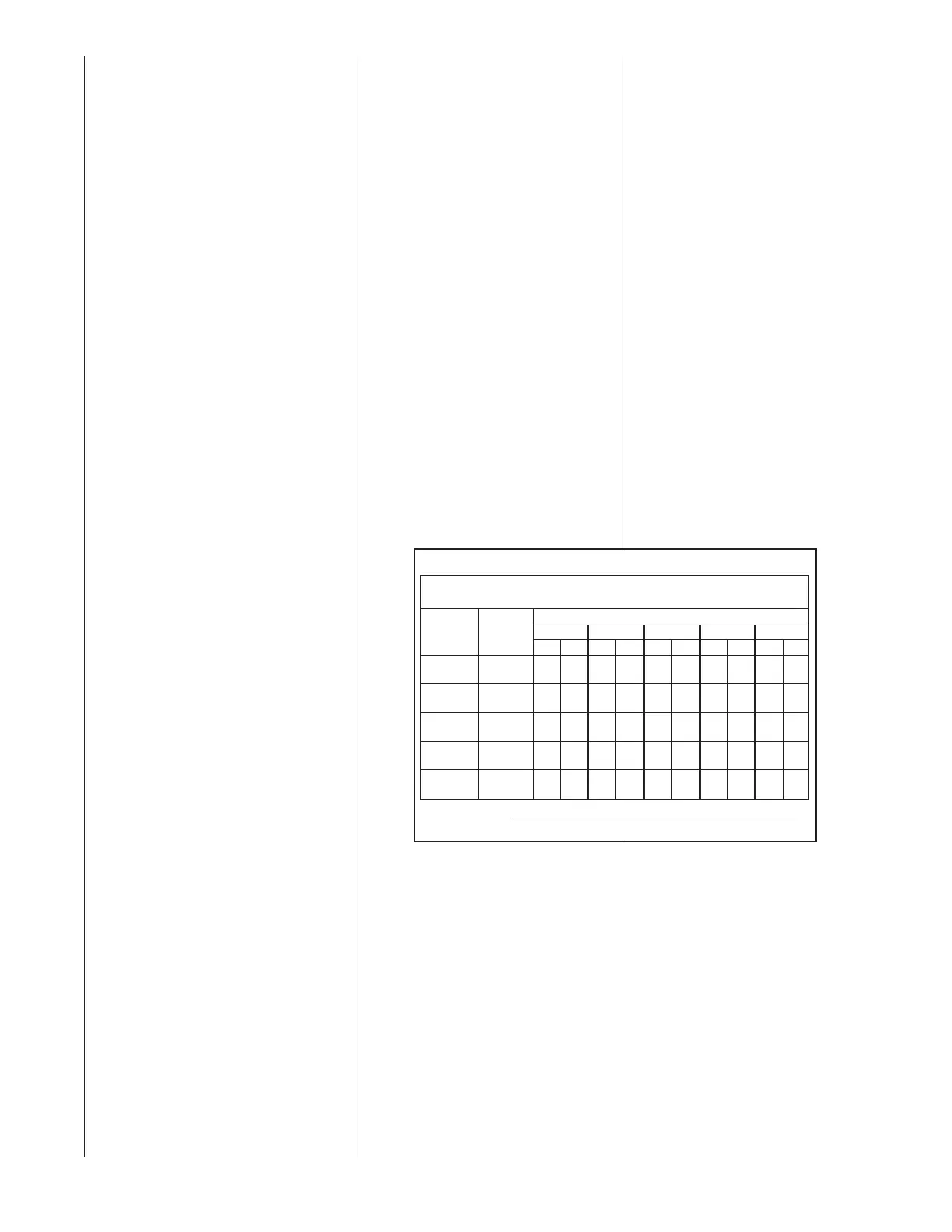

TABLE 4

ADJUSTING OR CHECKING

FURNACE INPUT

NATURAL GAS:

The maximum gas supply pressure to

the furnace should be 10.5” W.C. for

natural gas. The minimum gas supply

pressure for purposes of input adjust-

ment to the furnace should be 5” W.C.

A properly calibrated manometer or

gauge is required for accurate gas

pressure readings.

1. When adjusting the furnace input,

the high fire input should be

checked. The high fire manifold pres-

sure should be 3.5' W.C. Follow

these steps to be sure the furnace is

high fire mode:

a. With a single stage thermostat,

the furnace runs for 12 minutes on

low fire before shifting to high fire.

To be certain that it is on high fire,

jump terminals “W” and “W2” on

the control board in the blower

compartment.

b. With a two stage thermostat, set

the thermostat to its highest set-

ting to keep the furnace operating

in the high fire mode.

2. To adust high fire manifold pressure,

remove the adjustment cover screw

on the outlet end of the gas valve

and turn the adjustment screw clock-

wise to increase the pressure and

counterclockwise to reduce the pres-

sure. Replace the cover screw

securely.

3. The low fire manifold pressure

should be 1.7" W.C. As mentioned

above, the furnace remains in the

low fire mode for 12 minutes upon a

heat call with a single stage thermo-

stat. With a two stage thermostat,

disconnect the thermostat lead to the

“W2” terminal on the control board

and the furnace will remain in the low

fire mode. To adjust the pressure,

remove the regulator cover, on top of

the valve, and adjust as noted under

Step 2, above. After the adjustment

replace the screw cover securely.

NOTE: Use a 3/32⬙ allen wrench for

making the pressure adjustment.

LP GAS:

Furnaces for use on LP gas, the LP gas

supply pressure must be set between

11.0” and 13.0” W.C. by means of the

tank or branch supply regulators. The

furnace manifold pressure should be

set at 10” W.C. at the gas control valve.

For elevations up to 7,000 feet, rating

plate input ratings apply. For high alti-

tudes (elevations 7,000 and over) and

for any necessary major changes in the

gas flow rate the orifice spud must be

changed.

TO CHANGE ORIFICE SPUDS:

1. Shut off the manual main gas valve

and remove the gas manifold.

2. Replace the orifice spuds.

3. Reassemble in reverse order.

4. Turn the gas supply back on and

check for leaks.

5. Check for proper operation and set

to proper manifold pressure.

Check of input is important to pre-

vent over firing of the furnace

beyond its design-rated input.

NEVER SET INPUT ABOVE THAT

SHOWN ON THE RATING PLATE.

TO CHECK FURNACE INPUT:

1. Make certain that all other gas

appliances are shut off, with the

exception of pilot burners.

2. Start the furnace

3. Time the meter to measure the

time required to burn one cubic

foot of gas.

4. Use Table 4 to determine input

rate.

METER TIME IN MINUTES AND SECONDS FOR NORMAL

INPUT RATING OF FURNACES EQUIPPED FOR NATURAL OR LP GAS

INPUT

BTU/HR

METER

SIZE

CU. FT.

HEATING VALUE OF GAS BTU PER CU. FT.

900 1000 1040 1100 2500

MIN. SEC. MIN. SEC. MIN. SEC. MIN. SEC. MIN. SEC.

ONE 15112 1 15 1 18 3 20

50,000

TEN 10 50 12 00 12 30 13 12 30 00

ONE 0 44 0 48 0 50 0 53 20

75,000

TEN 7 12 80819 8 48 20 0

ONE 0 33 0 36 0 38 0 40 1 30

100,000

TEN 5 24 60615 6 36 15 0

ONE 0 26 0 29 0 30 0 32 1 12

125,000

TEN 4 19 4 48 50517 12 0

ONE 0 31 0 24 0 25 0 26 10

150,000

TEN 3 36 40410 4 20 10 0

Heating Value of Gas (BTU/Ft

3

) x 3600 x correction factor

Input BTU/HR =

Time in Seconds (for 1 cu.ft.) of Gas

22

Loading...

Loading...