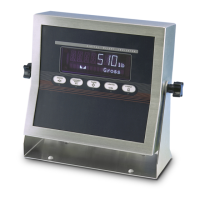

The IQ plus® 800/810 is a versatile digital weight indicator and process controller, offering a wide array of standard and optional features for various weighing applications.

Function Description:

The IQ plus 800/810 indicators are designed for basic to complex weighing applications, functioning as expandable, programmable process controllers. They can operate from either a 110VAC or 220VAC 3-wire power supply at 50 or 60 Hz. The device features a 10-key numerical keyboard and LED indicators for user interaction and status display. It includes a single-scale load cell input, expandable to four scales, and supports a load cell excitation voltage capable of driving 32 (700-Ω) or 16 (350-Ω) load cells. Configuration can be done via the front panel or downloaded from a personal computer or ASCII terminal. Calibration is performed through the front panel with internal memory storing calibration constants, allowing for field-replacement of complete units or components without recalibrating.

Standard features include three digital inputs (TTL or switch closure) configurable for keyboard functions or batching operations, and 20 fully programmable setpoints (continuous or batch steps) with four digital setpoint outputs (expandable to 16 with an expander module). It has one Electronic Data Processing (EDP) serial port configurable as duplex RS-232 or 20mA current loop (with optional RS-485), and one serial printer port configurable for simplex RS-232 and/or simultaneous 20mA current loop. An accumulate function is standard, along with formattable custom printing, including time, date, and custom headers. Both analog and exclusive digital RattleTrap® vibration filtering are integrated. The Truck In/Out program supports 200 IDs and offers six operating modes.

Important Technical Specifications:

- Analog Input: Full Scale Input Signal: 5 to 39 mV (including deadload); Analog Signal Input Range: 0.6 mV/V - 3.9 mV/V; Analog Signal Sensitivity: 0.3 microvolts/graduation minimum, 1.0 microvolt/grad recommended; Input Impedance: > 10 MΩ; Noise (Referred to Input): 0.3 µV p-p with 2 Hz analog filter, digital filter 4; Internal Resolution: Selectable 300,000 - 740,000 counts; Display Resolution: >100,000 dd; Measurement Rate: 20 Meas/sec, nominal; System Linearity: Within 0.01% of FS; Zero Stability: 140 nV/°C maximum; Span Stability: 3.5 ppm/°C maximum.

- Digital Inputs: 3 inputs, TTL or switch closure, active-low, special-purpose setpoint supervisor input.

- Digital Outputs: 4 outputs, open collector with TTL pullup, 250 mA sink, 40 V withstand. Optional: 12 additional 250 mA sink, 40 V DC withstand.

- Serial Communication: EDP Port: 19200, 9600, 4800, 2400, 1200, 600, 300 baud. Full duplex RS-232, simplex 20 mA Current Loop. Duplex 20 mA, RS-485 optional. Printer Port: 19200, 9600, 4800, 2400, 1200, 600, 300 Baud. Simplex RS-232, or simplex 20 mA Current Loop. Both ports selectable for RS-232 or 20 mA current loop standard, with 7 or 8 data bits and none, odd, or even parity.

- Display: 14 mm (0.55 inch), 14-segment vacuum fluorescent, 7 full digit display. Decimal point available at each digit. Eight red LED annunciators.

- Power: Line Voltages: 120 or 240 VAC +10% / –15%; Frequency: 50 or 60 Hz; Power Consumption: 12 VA (minimum config), 30 VA (all options).

- Environmental: Operating Temperature: –10 to +40°C (legal), –10 to +50°C (industrial); Storage Temperature: –25 to +70°C.

- Enclosure: IQ plus 800 (compact stainless steel) and 810 (desktop (DT), stainless steel batching (SS), hostile environment batching (HE)). NEMA 4X washdown certified for 800 SS, 810 SS, and HE models. NTEP-certified for Class III and IIIL at 10,000 divisions.

Usage Features:

The front panel includes keys like ZERO, G/N (Gross/Net), TARE, UNITS, PRINT, DISP TARE, TIME/DATE, DISP ACCUM, DISP ROC, NEW I.D., and SCALE # (or BASE # for HE models).

- Numeric Keypad: For data entry.

- ZERO: Eliminates weight from display (Gross mode), not functional during motion or beyond selected zero range.

- G/N: Toggles between Gross and Net display modes.

- TARE: Zeroes displayed weight and stores it in the tare register. Can be push-button or keyed tare.

- UNITS: Toggles between primary and secondary units.

- PRINT: Prints a ticket in Normal Weighing Mode, or operates as data entry key in Truck In/Out Modes. Customizable ticket formats.

- DISP TARE: Displays current tare weight (Normal mode) or scrolls through stored IDs (Truck In/Out mode).

- TIME/DATE: Displays date/time, allows entry of new values.

- DISP ACCUM: Displays current weight from accumulator register, allows access to five accumulators.

- DISP ROC (optional): Displays rate of change for weight data.

- NEW I.D.: Enters new truck ID number (Truck In/Out mode).

- SCALE # (optional): Selects analog input channel or total of all channels to display.

- SET POINT: Accesses and changes setpoint values.

- CLEAR: Erases digits, clears special function values (setpoints, accumulator, tare, truck IDs).

Operating Modes:

- Setup Mode: Accessed by moving a switch on the CPU board, disables normal weighing functions, allows configuration and calibration.

- Normal Mode: Standard weighing operations, gross/net display, push-button or keyed tares.

- Truck In/Out Modes (6 modes): Handles multiple truck ID numbers and tare weights. Features include stored IDs (up to 200), keyed tares, and value swapping (assigns lesser of two weights as tare).

Optional and Advanced Features:

- Rate of Change Function: Displays weight change over time.

- Peak Hold Function: Holds display on highest net weight achieved during a weighing cycle.

- Bar Graph: 48 LED segments to represent weight, speed, or batch step progress.

- Passwords: Two passwords for configuration menus and setpoint configuration.

- Expansion Board: Provides additional room for options like dual load cell input, analog output, and auxiliary serial port.

- Relay Boards: 2-, 4-, and 16-channel relay modules for controlling external equipment.

- Analog Output Modules: 0-10V DC or 4-20mA output.

- Setpoint Digital Output Expander: Adds 12 digital output terminals (total 16).

- Expanded Serial Communication: Duplex 20 mA current loop and RS-485 for EDP port.

- Supervisor Setup Switch: Allows access to setpoint configuration menu without opening the case.

- Start/Stop/Run Batching Switch: For batching operations.

- Jetpak™ 100-Hz High Speed Option: 100 updates per second.

- Allen-Bradley Remote I/O Interface: Communicates with PLC/SLC controllers.

- Recipe Storage Option: Stores up to nine recipes, each with 16 setpoints.

Maintenance Features:

- Battery Replacement: A 3.0V Lithium battery on the power supply/display board maintains the real-time clock and protects RAM. Recommended replacement every two years or as needed.

- Troubleshooting: Error messages on the display guide troubleshooting for wiring, jumper blocks, excitation voltages, configuration, calibration values, and software revision.

- Data Saving and Transfer: Configuration data and setpoints can be printed, saved to floppy disk, or transferred directly between indicators using the EDP port. Hotline™ software simplifies these tasks.