32DSSP01.A

3 - 1

III. S-SERIES PERSONAL USE MAINTENANCE

egular maintenance of the RICON S-Series Personal Use Wheelchair Lift is required to pro-

vide optimum performance and reduce the need for repairs. This chapter contains cleaning

instructions, a maintenance schedule, and decal information.

WARNING!

THIS RICON PRODUCT IS HIGHLY SPECIALIZED. MAINTENANCE AND REPAIRS MUST

BE PERFORMED BY A RICON AUTHORIZED DEALER USING RICON REPLACEMENT

PARTS. MODIFYING OR FAILING TO PROPERLY MAINTAIN THIS PRODUCT WILL VOID

WARRANTY, AND MAY RESULT IN UNSAFE OPERATING CONDITIONS.

A. MAINTENANCE INFORMATION

Additional maintenance information is available in the S-Series Personal Use Service

manual, part number 32DSSP02. This manual is available from Ricon in printed hard

copy, or the Ricon website in PDF format. The website is located at

www.riconcorp.com. Click on RICON CORPORATION and then DEALER’S ROOM at the

website. Entry to the dealer’s room will require a Dealer Number and a Password.

B. CLEANING

Regular cleaning with mild soap (i.e. dish soap or car wash liquid) and drying thoroughly

will protect lift painted surfaces. Cleaning is especially important in areas where roads

are salted in winter. Make sure that lift pivot points are clean and dry prior to lubrication.

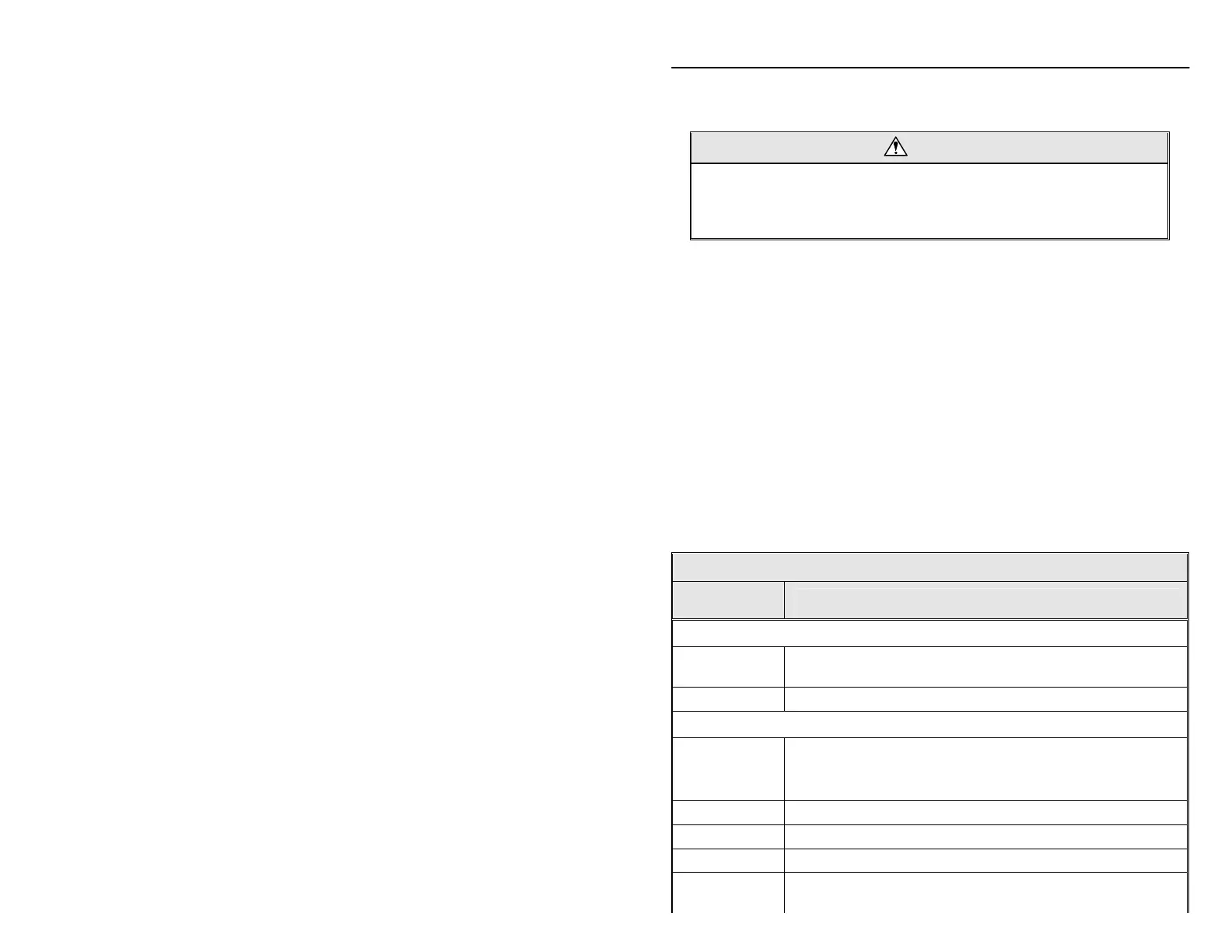

C. MAINTENANCE SCHEDULE

Under normal operating conditions, maintenance inspections are required at least every

six months (1750 cycles) and a thorough inspection should be performed at service in-

tervals in Table 3-1. Service should be increased during heavy use (more than 10 cy-

cles per day).

TABLE 3-1: MAINTENANCE SCHEDULE

SERVICE

POINT

ACTION TO PERFORM

DAILY SAFETY CHECK

Overall Condition Listen for abnormal noises as lift operates (i.e. grinding or binding

noises.)

Control Pendant Verify that control pendant is undamaged and cable connectors are tight.

TWO WEEK SAFETY CHECK

Overall Condition § Listen for abnormal noises as lift operates (i.e. grinding or binding

noises.)

§ Inspect underside of vehicle for anything that is out of place.

Control Pendant Verify that control pendant is undamaged and cable connectors are tight.

Electrical Wiring Inspect electrical wiring for frayed wires, loose connectors, etc.

Vehicle Interlock Place vehicle in NON-INTERLOCK mode and attempt to operate lift.

Decals Verify that lift decals are properly affixed, clearly visible, and legible.

Replace, if necessary.

Loading...

Loading...