Do not use E15 or E85 fuel

in this product. Only use un-

leaded gasoline containing

up to 10% ethanol. It is a violation of federal law

and will damage the unit and void your warranty.

Ne pas utiliser d’essence E15 ou E85 dans ce

produit. Utiliser seulement de l’essence sans

plomb ne contenant pas plus de 10 % d’éthanol.

Une telle utilisation représente une violation de la

loi fédérale et endommagera l’appareil et annulera

la garantie.

No utilice combustibles E15 o E85 con este

producto. Utilice únicamente gasolina sin plomo

que contiene hasta 10% de etanol. Esto constituye

una violación a la ley federal, dañará la unidad y

anulará la garantía.

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

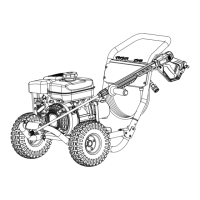

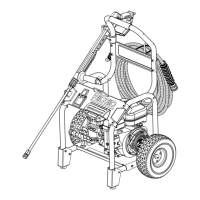

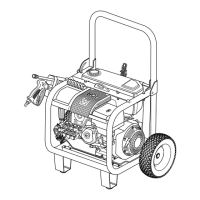

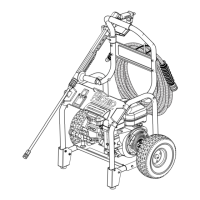

3300 PSI PRESSURE WASHER

NETTOYEUR HAUTE PRESSION

DE 3 300 PSI

LAVADORA A PRESIÓN DE 3 300 PSI

RD80956

To register your RIDGID

product, please visit:

http://register.RIDGID.com

Pour enregistrer votre

produit de RIDGID, s’il

vous plaît la visite :

http://register.RIDGID.com

Para registrar su producto

de RIDGID, por favor visita:

http://register.RIDGID.com

Your pressure washer has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using this

product. If you do not understand the warnings and instructions in the operator’s manual, do not use this product.

Ce nettoyeur haute pression à essence a été conçu et fabriqué

conformément à nos strictes normes de fiabilité, simplicité d’emploi

et sécurité d’utilisation. Correctement entretenu, cet outil vous

donnera des années de fonctionnement robuste et sans problème.

AVERTISSEMENT :

Pour réduire les risques de blessures, l’utilisateur doit

lire et veiller à bien comprendre le manuel d’utilisation

avant d’employer ce produit. Si tous les avertissements

et toutes les consignes de sécurités et instructions du

manuel d’utilisation ne sont pas bien compris, ne pas

utiliser ce produit.

Su lavadora de presión de gasolina ha sido diseñado y fabricado de

conformidad con nuestras estrictas normas para brindar fiabilidad,

facilidad de uso y seguridad para el operador. Con el debido cuidado,

le brindará muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA:

Para reducir el riesgo de lesiones, el usuario debe leer y

comprender el manual del operador antes de usar este

producto. Guarde este manual del operador y estúdielo

frecuentemente para lograr un funcionamiento seguro y

continuo de este producto

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

SAVE THIS MANUAL FOR FUTURE REFERENCE

NOTICE AVIS AVISO