This document is an operator's manual for a RIDGID gasoline pressure washer, models RD80746 and RD80947. It provides comprehensive instructions for safe operation, assembly, maintenance, and troubleshooting of the device.

The pressure washer is designed for cleaning various surfaces and objects using a high-pressure water stream. Its primary function is to remove dirt, mold, and other debris from decks, cement patios, house siding, cars, boats, motorcycles, outdoor furniture, and grills. The device utilizes a gasoline engine to power a pump that generates the high-pressure water.

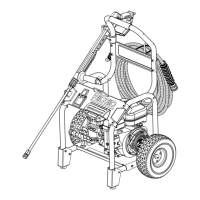

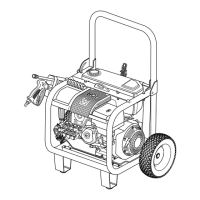

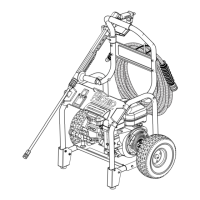

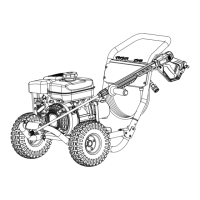

Key usage features include a trigger handle with a lock-out mechanism for safety and control, and a spray wand that allows the user to direct the water stream. The pressure washer comes with various nozzles, each designed for a different spray pattern and cleaning intensity. These include 25° for general purpose cleaning, 15° for tough jobs, 0° for spot cleaning or high-to-reach areas, and a Dual Power Soap Nozzle for detergent application. The Dual Power Soap Nozzle can be adjusted for long or short range cleaning, and the detergent dial allows for the use of either a built-in detergent container or external detergent bottles. The engine switch is used to start and stop the engine, working in conjunction with the recoil starter grip. A choke lever assists in starting a cold engine. The handle can be raised or lowered for user comfort and storage. For mobility, the pressure washer is equipped with wheels, allowing it to be tilted and rolled to the desired position.

Safety is a paramount concern, and the manual emphasizes several rules. Users are warned against directing the water stream at people, pets, or electrical devices, and to always wear safety glasses. The lock-out feature on the trigger handle prevents unauthorized use and accidental spraying. The manual also highlights the importance of using the correct nozzle for the job to avoid surface damage and never changing nozzles without engaging the lock-out. When handling fuel, users are instructed to refuel outdoors, avoid smoking, and clean up any spills immediately due to the highly flammable and explosive nature of gasoline vapors. The thermal relief valve is a safety feature that prevents water temperatures from reaching harmful levels by releasing a small amount of water, resetting once the water cools.

Maintenance features are detailed to ensure the longevity and optimal performance of the pressure washer. Regular checks include ensuring all bolts and nuts are securely tightened, and inspecting and cleaning the air filter. The air filter, if dirty, can cause starting difficulties, loss of performance, and shorten engine life, so it should be cleaned monthly and replaced annually. The manual provides instructions for washing the air filter with soapy water, rinsing, drying, and applying a small amount of motor oil before reinstallation. Oil changes are also covered, with instructions on draining old oil and refilling with new 4-stroke engine oil. Checking and cleaning the spark plug is another maintenance task, involving cleaning carbon deposits and adjusting the electrode gap. Nozzle maintenance is crucial for preventing excessive pump pressure and pulsing; the manual advises using the provided nozzle cleaning tool to clear any clogs and back-flushing with a garden hose. Proper storage is also outlined, including draining the fuel tank, engine oil, and all water from hoses and the pump, especially in frost-prone areas. The manual recommends using a fuel stabilizer and pump saver to enhance performance and extend the machine's life. Before storing, the auxiliary handle and spray wand should be removed and stored in their designated areas. For preparing the machine for use after storage, instructions include cleaning oil from the combustion chamber, wiping the spark plug, and refilling the fuel tank.