11

INSTALLATION

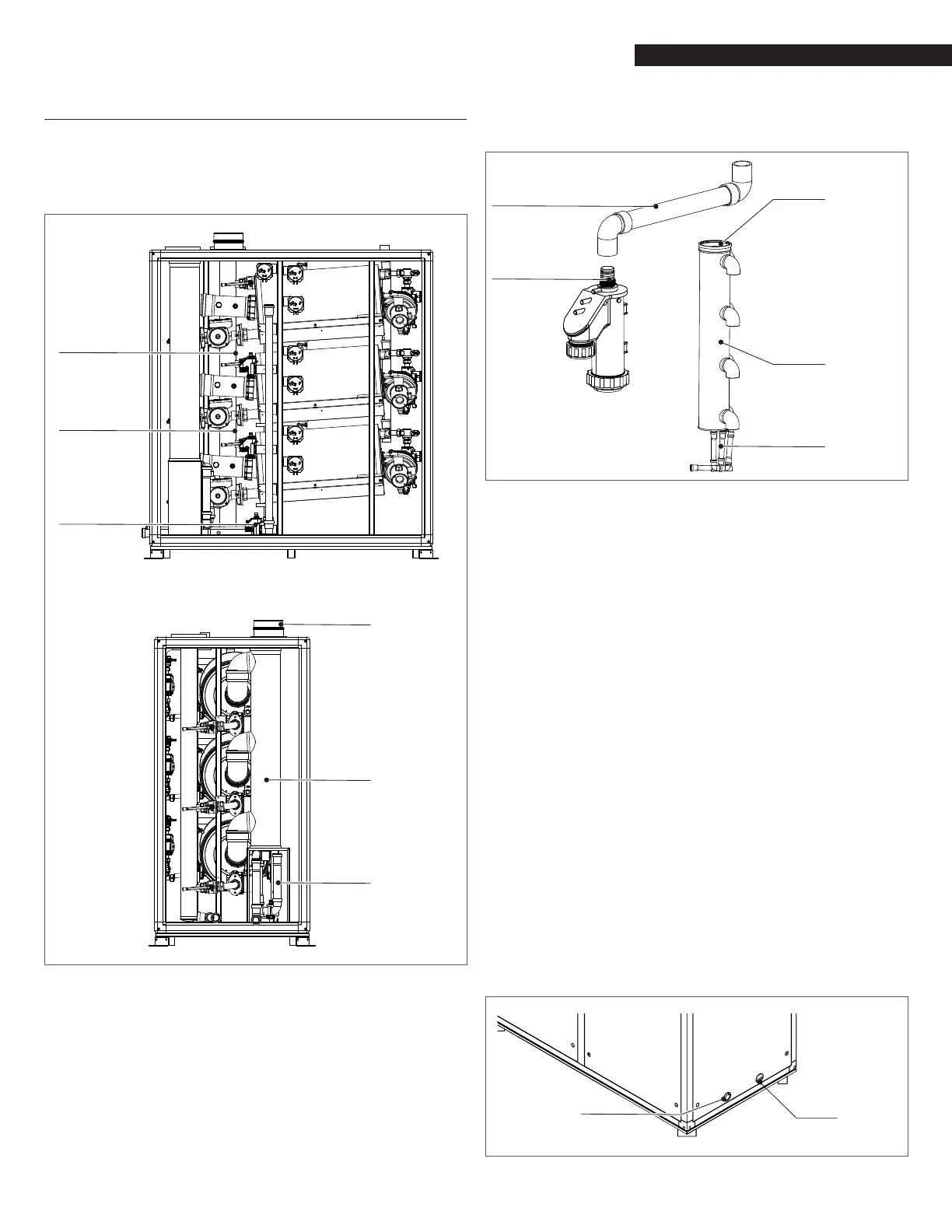

2.10 Condensate drain and piping

The Array Boiler is designed to condense water vapor from the ue

products. Each module of the boiler is equipped with a conden-

sate trap (see Fig. 11), while a syphon collects the condensate of

the vertical ue manifold.

water from the top

of the vertical flue

manifold BEFORE

to connect

the vent piping

Vertical Flue

Manifold

Syphon

Condensate

Trap

Condensate

Trap

Condensate

Trap

Fig. 11

Condensate Drain System

9

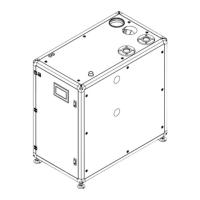

WARNING: At the Start-up and after prolonged shutdown of

the boiler, the condensate traps and the syphon must be lled

with water prior to restart it, otherwise combustion gases will

enter the room with a risk of an excessive level of carbon

monoxide.

The procedure for lling the traps and syphon with water is shown

on the Fig. 12:

Vertical Flue

Manifold

Syphon

Disconnect the

condensate pipe

Fill the trap

with water

Fill the syphon

the top of the

vertical flue

manifold

BEFORE to

connect the

vent piping

Fig. 12

Water Filling of Condensate System

− The installation must have provisions for suitable drainage

or collection of the condensate out of the boiler traps.

− The condensate water shall be discharged at atmospher-

ic pressure, by dripping into a suitable drain, and shall be

neutralized prior to draining per local codes.

− The condensate drain tube must pitch away from the boiler

(1/4” slope per foot) and must never reduce its diameter

downstream.

− Never use copper pipes or of other material not intended

for the specic purpose, because the action of condensate

will cause a rapid deterioration.

− Check that the condensate drain pipe is adequately sloping

towards the discharge point avoiding high points, which can

inhibit the ow of condensate. The condensate pipe must be

installed in such a way so as to avoid the freezing of the liquid.

9

WARNING: Verify condensate disposal / neutralization is in ac-

cordance with local, state and federal regulations.

If a oor drain is not available, a condensate pump can be used to

remove the condensate to drain. The maximum condensate ow

rate is 7.9 GPH for Array AR 1000, 13.9 GPH for Array AR 1500 and

15.9 GPH for Array AR 2000. The drain line must be removable for

routine maintenance.

9

CAUTION: Use PVC, CPVC, stainless steel, aluminum or polypro-

pylene for condensate drain piping (Fig. 12). DO NOT use carbon

or copper components.

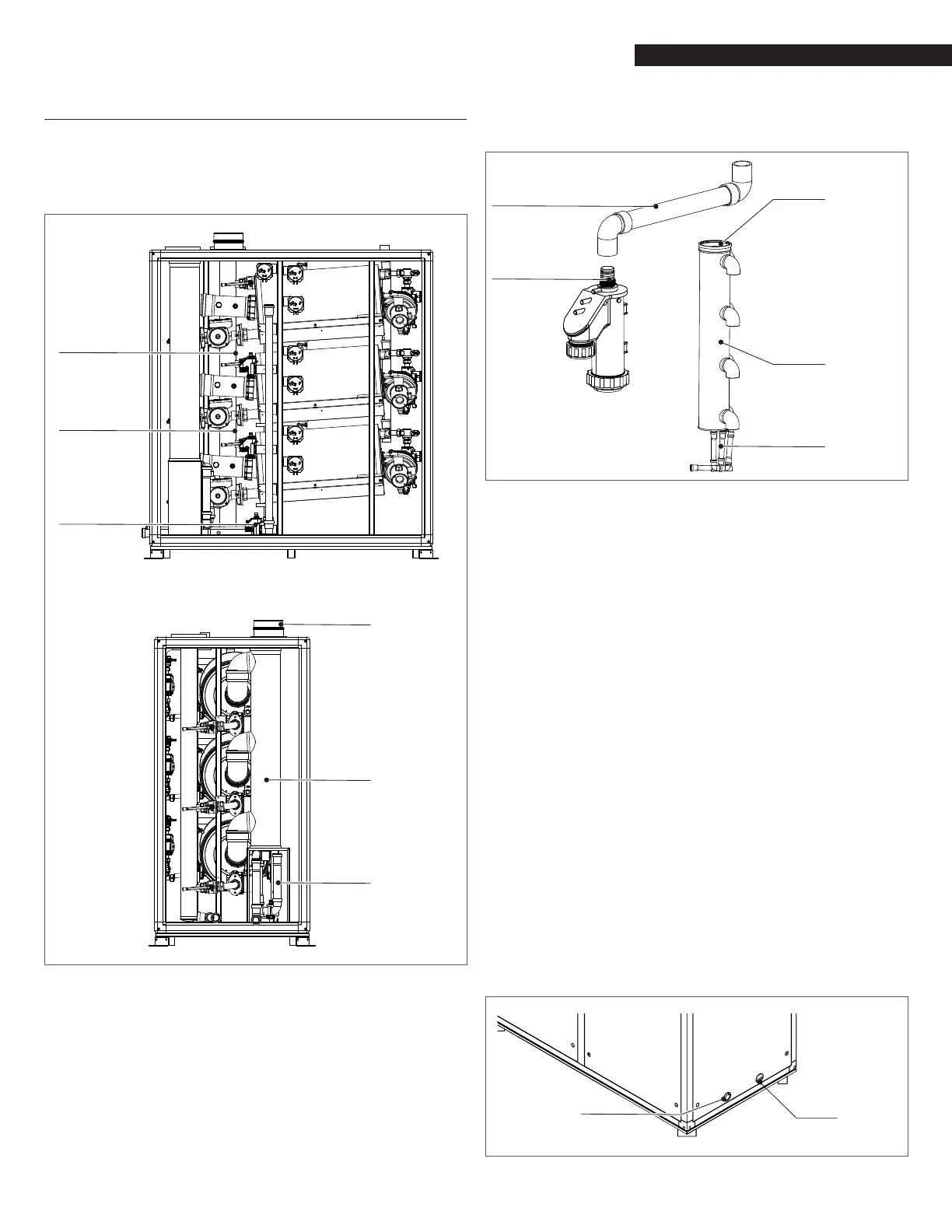

Condensate

Relief Valves

Manifold

Fig. 13

Condensate Drain and Relief Valves Manifold Locations

Loading...

Loading...