10

INSTALLATION

Excessive water hardness causing a lime buildup in the stainless

steel coils or tubes is not a fault of the appliance and is not cov-

ered by warranty. Water hardness must fall within the following

limits:

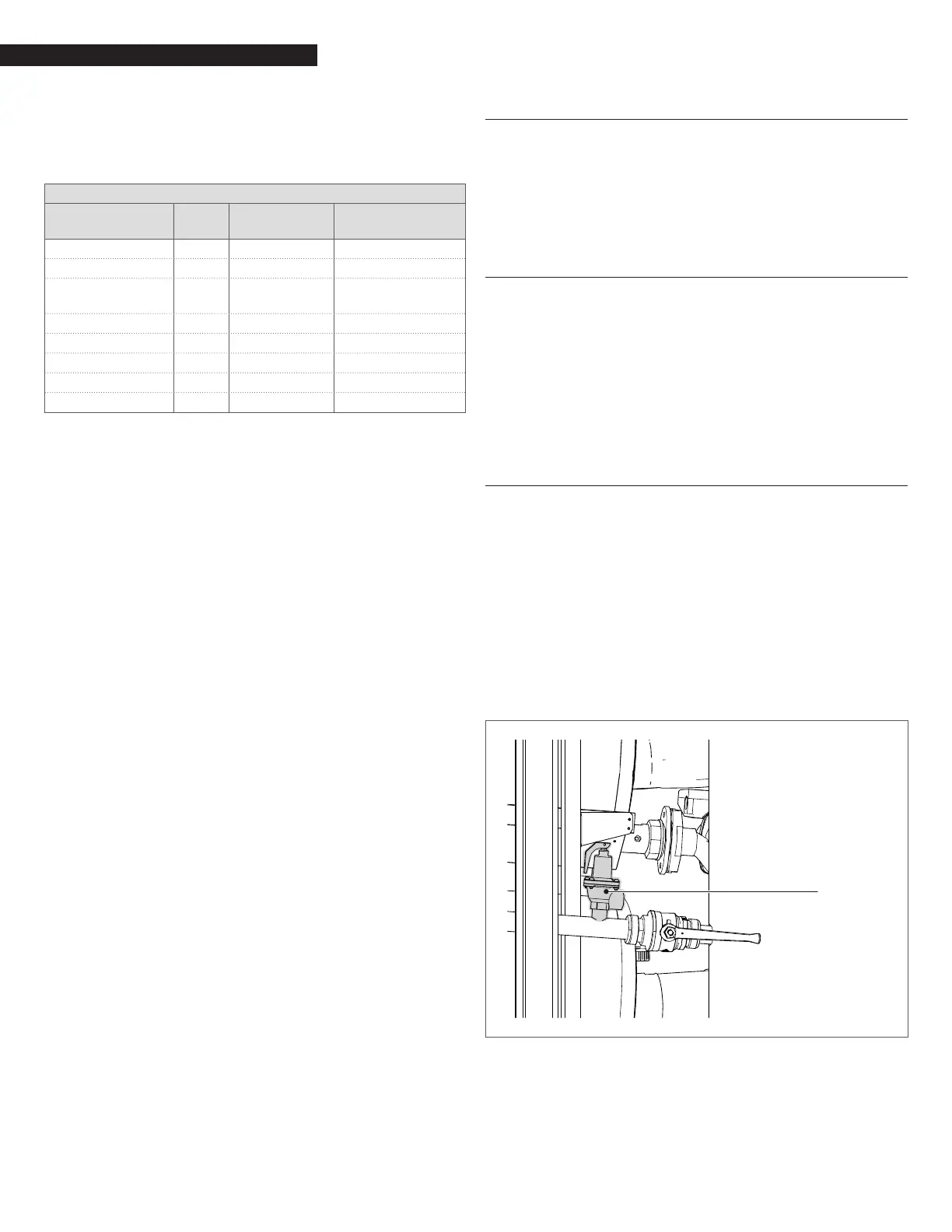

STEEL BOILERS - With furnace power > 500kBTU/h

Water used

for rst lling

Water with

system operating

ph 6 - 8 7.5 – 9.5

Hardness ppm < 50 < 50

Electrical Conduc-

tivity

ppm < 67

Chlorides ppm < 10

Sulphides ppm < 10

Nitrides ppm < 10

Oxygen in Solution ppm

Iron ppm < 0.5

− Use only untreated water to ll the system.

− Do not use TSP (tri-sodium phosphate).

− Do not use ll water treated with salt bedding type ex-

changers (ion exchanger).

− Never introduce non-approved boiler treatment or similar

additives.

− Consult a local water treatment specialist for recommenda-

tions if any of the above is outside the stated ranges.

− When using oxygen permeable PEX, the system must be

separated from the boiler by a heat exchanger.

− A correctly sized and working expansion vessel must be in-

stalled.

− Do not exceed the maximum permissible ow rate through

the boiler. Excessive ow can cause erosion damage to the

heat exchanger.

9

CAUTION: Before connecting the boiler to the heating system,

ush the heating system to remove sediment, ux, dirt, and

other foreign matter. The heat exchanger may be damaged by

sediment or corrosion.

9

CAUTION: Do not use cleaning uids that are not compatible

with the boiler materials, including acids (e.g. hydrochloric

acid and similar ones) at any concentration.

9

CAUTION: Introducing fresh water to the system increases the

oxygen presence and can cause corrosion of metallic compo-

nents. Immediately repair any drips or leaks in the system to

avoid constant introduction of air into the system.

9

CAUTION: Excessive uctuation in pressure changes in the sys-

tem can cause fatigue and stress on the heat exchanger. This

is detrimental to the integrity of the boiler and system com-

ponents, it is mandatory to maintain a constant operating

pressure.

9

CAUTION: For freeze protection use only propylene glycol, with

scale inhibitors, with a maximum volume [concentration] of

50% of glycol. Frost protection and inhibitor level has to be

checked annually during the regular scheduled maintenance

of the condensing boiler.

A minimum water pressure is required for optimum performance.

Minimum water pressure required: 7.25 psi (0.5 bar).

2.7 Low water cutoff

A low water cut off (LWCO) is installed on each boiler.

To check the functionality of LWCO go to the 905PB inner display,

access the Settings menu, select Test mode, and then click on

LWCO1. On the screen will appear the error “MN: Low Water Cutoff

Error”.

At this point press the reset button. The error will turn off.

2.8 High limit safety switch

A high limit safety switch is installed on each module of the boiler.

To simulate a high limit lockout at 208°F go to the 905PB inner

display, access the Settings menu, select Test mode, then click on

Max temp.

The control will display “MN: Max. Thermostat Lock Error”.

At this point press the reset button on the removable display to

restart the module.

The same test can be carried out as described at section “4.3.8

Module Test Screen” pag. 27.

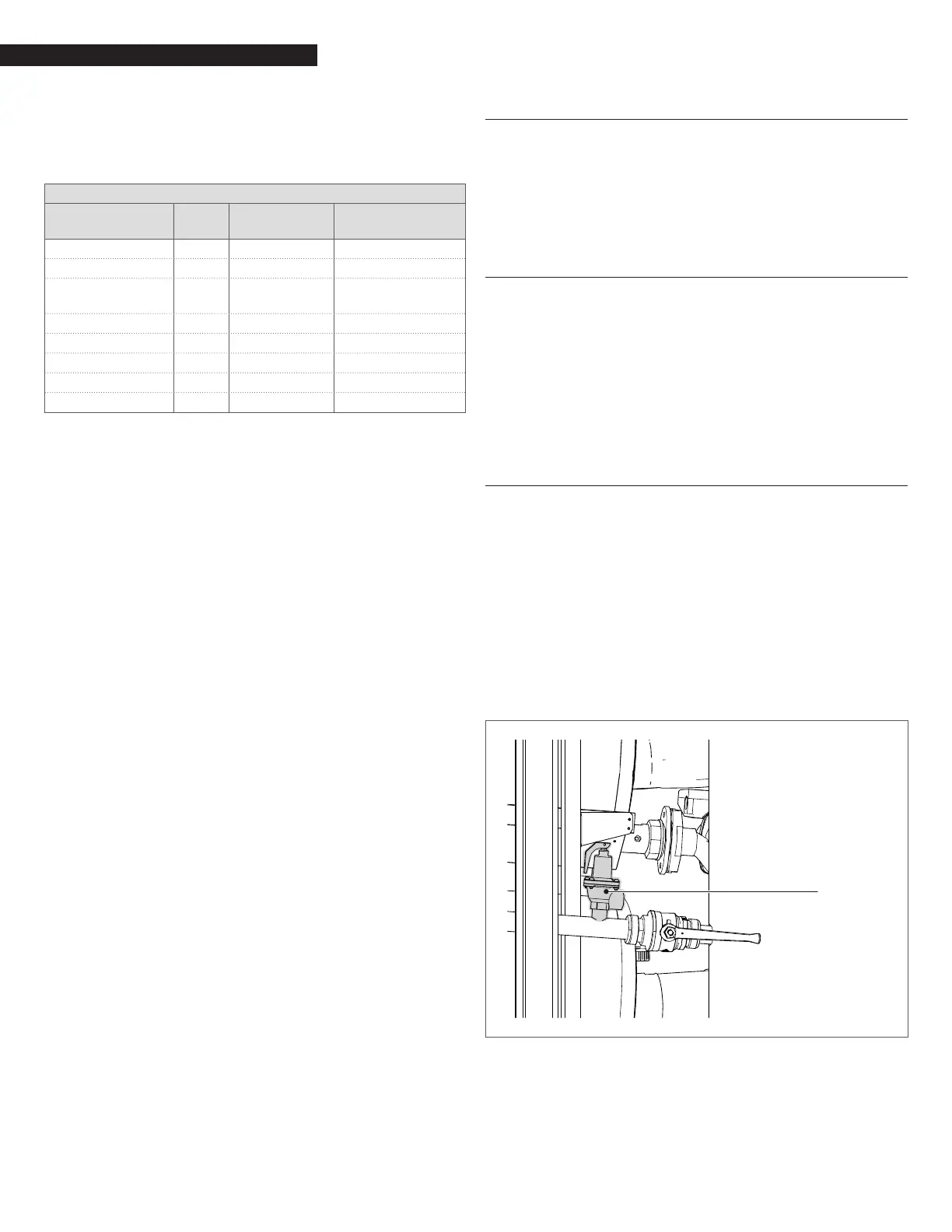

2.9 Pressure relief valve installation

ASME rated Pressure Relief Valves are factory installed in each Array

Boiler. The pressure rating for the relief valves is 75 PSI. The relief

valves are installed on each hot water horizontal manifold of the

boiler as shown in Fig. 10. The relief valves drain piping must be

connected to a nearby oor drain. In multiple unit installations

the discharge lines must not be manifolded together.

Each must be individually run to a suitable discharge location. Re-

lief valves should be manually operated at least once a year. If

a relief valve discharges periodically, this may be due to thermal

expansion in a closed water supply system.

Contact the water supplier or local plumbing inspector on how to

correct this situation.

Do not plug the relief valve.

75PSI Relief valve

(one for each module)

Fig. 10

Pressure Relief Valve Location

Loading...

Loading...