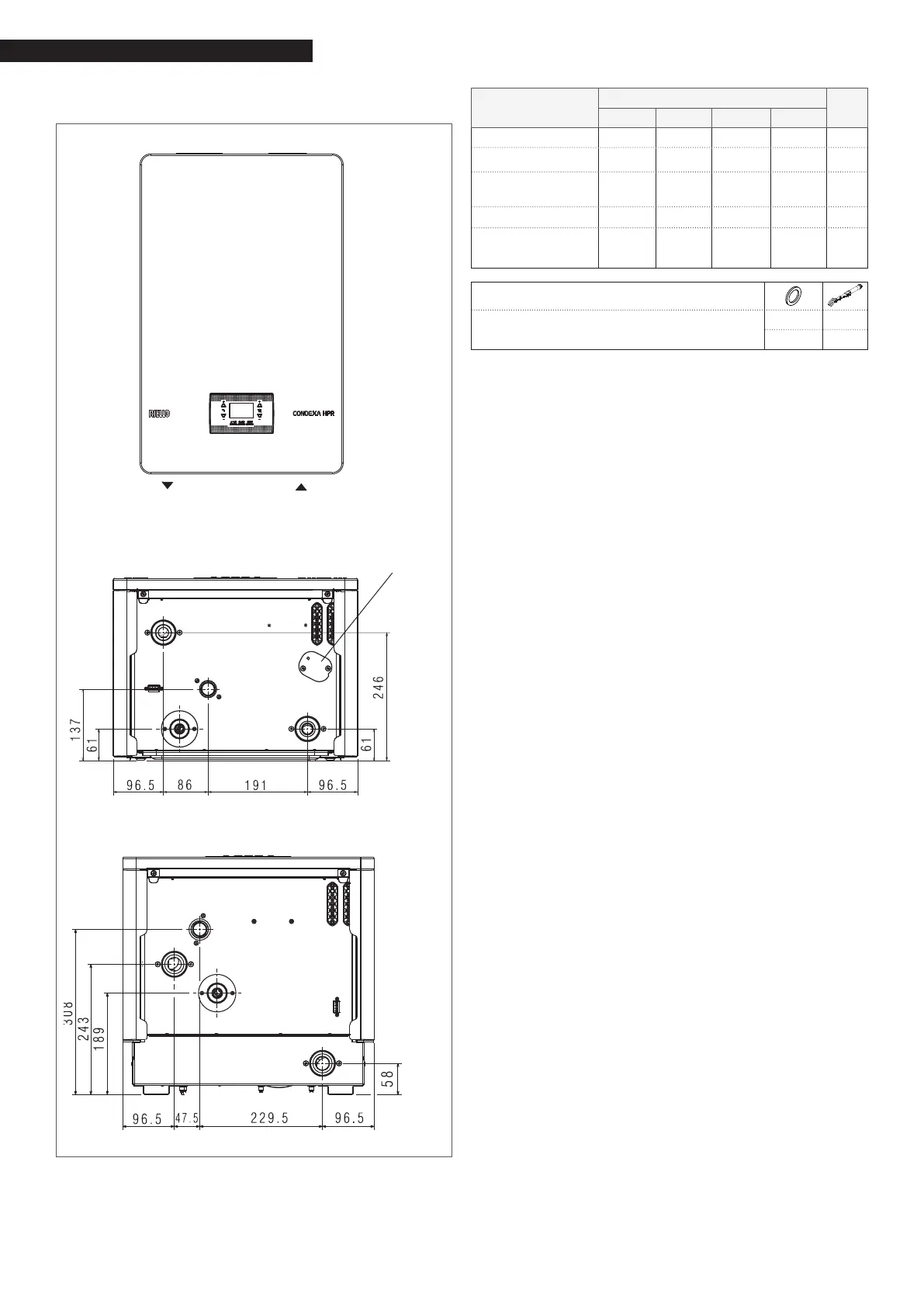

INSTALLATION

24

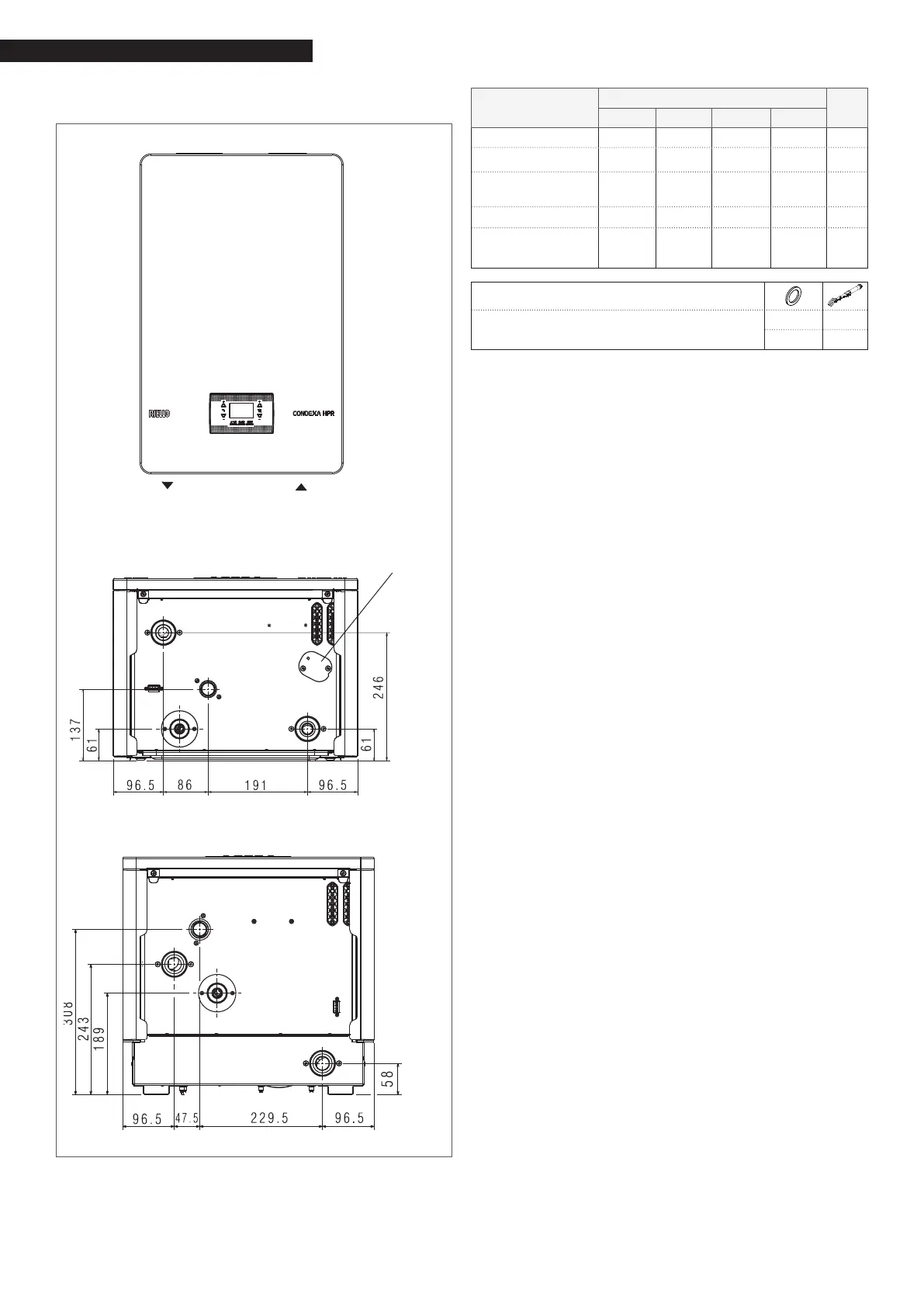

The dimensions and positioning of the thermal module

water ttings are shown in the table below.

diverting valve

connection

MI

RI

Condexa HPR 35-45

Condexa HPR 55-70

SC

Condexa HPR 35-45

Condexa HPR 55-70

G

G

SC

RI

RI

MI

MI

DESCRIPTION

Condexa HPR

35 45 55 70

MI (system delivery)

G 1" 1/2 M G 1" 1/2 M G 1" 1/2 M G 1" 1/2 M Ø

RI (system return) G 1" 1/2 M G 1" 1/2 M G 1" 1/2 M G 1" 1/2 M Ø

SC (condensate

discharge)

25 25 25 25

Ø

mm

G (gas inlet) G 3/4” M G 3/4” M G 3/4” M G 3/4” M Ø

diverter valve

connection

G 1” 1/2 M G 1” 1/2 M - - Ø

TIGHTENING TORQUE

Ø 3/4” 35Nm

Ø 1/2” 25Nm

9

Before connecting the boiler, the protection plugs

must removed from the delivery, return and con-

densate discharge pipes.

9

Before connecting the boiler, the system must be

cleaned. This step is vital when a replacement is

being made on a pre-existing system.

If the old generator is still installed in the system, when

cleaning you are advised to:

− add a de-scaling additive

− operate the system with the generator activated

for approx. 7 days

− discharge dirty system water and ush the system

out at least once with clean water

Repeat

the last step if the system is very dirty.

If the system is new or if the old generator is not tted

or available, use a pump to circulate the water with the

additive within the system for approx. 10 days, and then

carry out the nal washing procedure as described in

the previous point.

Once the cleaning operations have been completed, it is

advisable to add a suitable protective liquid to the sys-

tems water before installing the boiler.

To clean the internal water circuit of the heat exchanger,

contact the r

Aftersales Service.

a

Do not use incompatible liquid detergents, includ-

ing acids (for instance hydrochloric acid and simi-

lar) in any concentration.

a

Do not subject the heat exchanger to cyclical pres-

sure changes because fatigue stress is very danger-

ous for the system components.

Loading...

Loading...