INSTALLATION

28

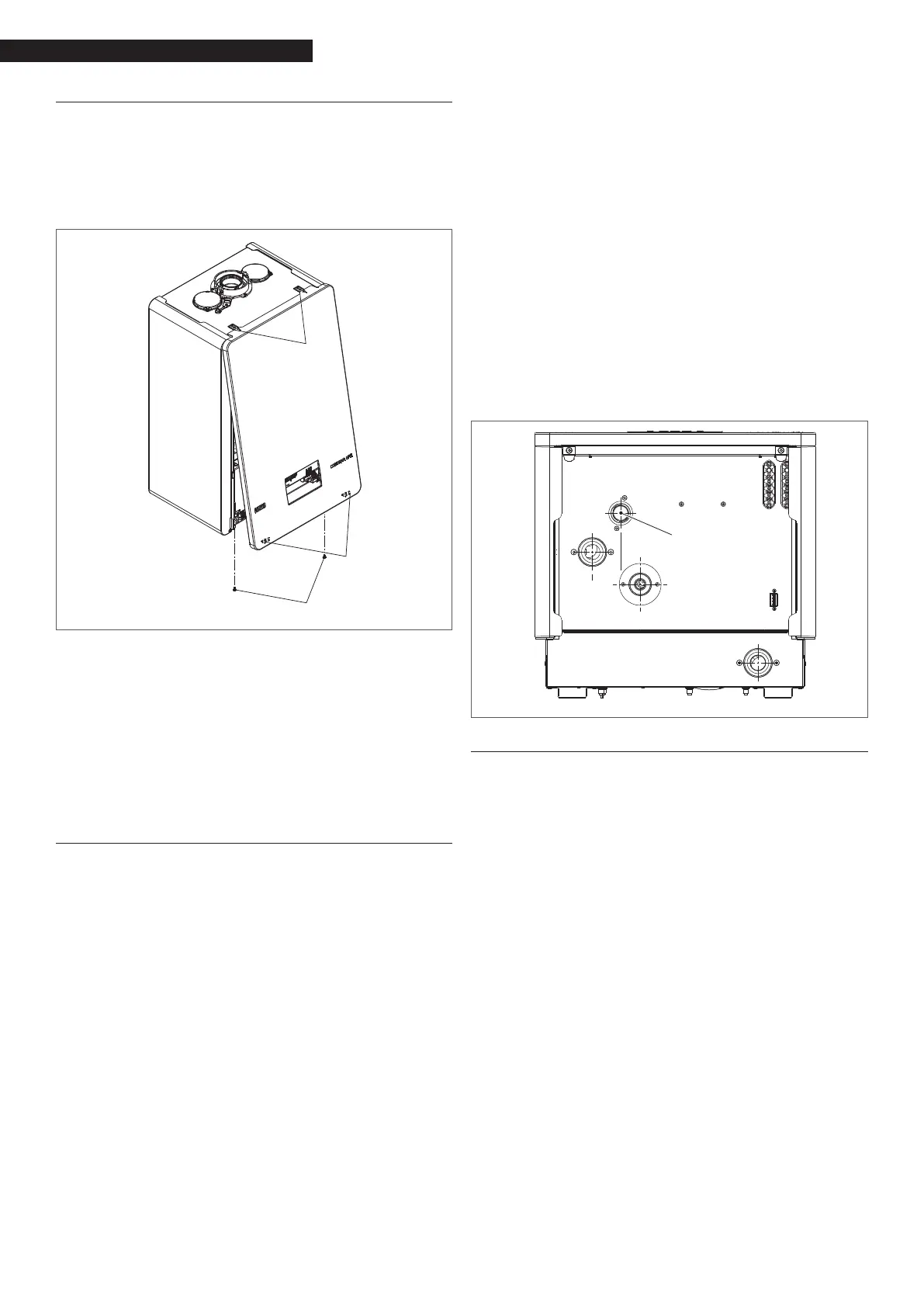

2.10 Removing the casing

To access the internal components, remove the casing as

explained below:

locate and loosen the 2 screws (A) xing the casing to

the boiler, levering the xing clips (C) and detaching

the lower part of the casing

raise the casing to release it from the upper tabs (B),

then remove it.

B

A

A

C

9

If the side panels are removed, ret them in their

initial position (referring to the label on the panel

itself).

9

If the front panel is damaged, it must be replaced.

9

The noise-absorbing panels in the front and side

walls ensure the airtight seal of the air supply duct

in relation to the place of installation.

9

It is therefore CRUCIAL to reposition the components

correctly to ensure the boiler seal.

2.11 Gas connections

The gas connection must be made respecting the instal-

lation regulations in force, and sized to ensure the cor-

rect gas delivery to the burner.

Before making the connection, check that:

9

The gas type is suitable for the appliance

9

If the appliance needs to be adapted for use with

another gasseous fuel, contact your local Aftersales

Service to have the necessary modications made.

These operations must not be carried out by the in-

staller under any circumstances.

9

The piping is thoroughly clean

9

The gas meter ow rate is capable of ensuring the

simultaneous use of all the appliances connected

to it. The appliance connection to the gas supply

line must be made in accordance with the current

regulations.

9

The intake pressure with the appliance OFF has the

following reference values:

− powered by methane gas: optimal pressure 20

mbar

− powered by LPG: optimal pressure 37 mbar

a

Do not use fuels other than those envisaged, for

any reason whatsoever.

While it is normal for the intake pressure to decrease while

the appliance is operating, it is a good idea to check that

there are no excessive pressure uctuations. In order to

limit the extent of these variations, the diameter of the

gas supply line must be dened according to the length

and the pressure drops of the line itself, from the meter

to the boiler.

9

If uctuations in the gas distribution pressure are

encountered, you are advised to install a pressure

stabiliser upstream of the appliance’s gas inlet. For

G31 gas supply, all the necessary precautions must

be taken to prevent the fuel gas from freezing in

the event of extremely low outdoor temperatures.

If the gas distribution network contains solid particles,

install a lter on the fuel supply line. When selecting it,

bear in mind that pressure drops due to the lter should

be as low as possible.

9

Once the installation is complete, check that the

joints are perfectly sealed.

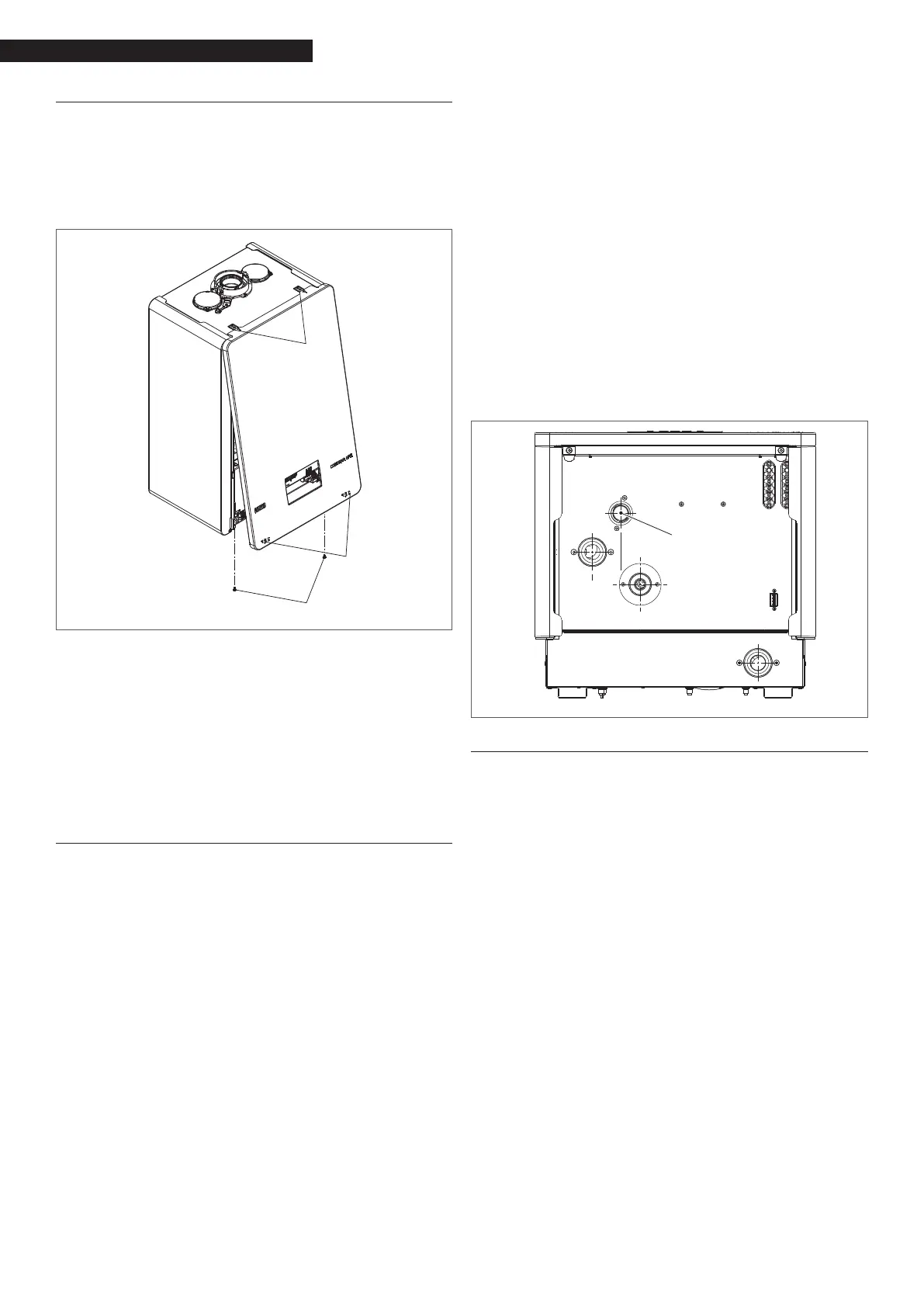

GAS 3/4" M

Discharging the ue gases

2.12 Electrical wiring

The CONDEXA HPR thermal module leaves the factory ful-

ly wired, and only needs to be connected to the main

power supply and the system components.

9

It is mandatory:

− to use an omnipolar magnetothermal switch, a

line disconnector, complying with CEI-EN stand-

ards (contact opening of at least 3mm)

− to refer to the wiring diagrams in this booklet

when connecting the system components and

carrying out any electrical task.

9

The use of adaptors, multiple sockets and exten-

sions to power the appliance is not allowed.

9

Any work on the electrical system must only be car-

ried out by qualied personnel in compliance with

all legal provisions, paying special attention to the

safety regulations.

9

The supply cable is not supplied as standard. The

connection to the mains supply must be made us-

ing FROR 3G1.5 type cables (standardised by CEI 20-

27) or the equivalent.

9

Secure the cables with ties to ensure they are cor-

rectly positioned inside the appliance.

9

It is vital that the electricity cables and those for

the low voltage system components (room/heating

request thermostat, outdoor temperature sensors,

etc.) are separated

.

9

The installer is responsible for ensuring the appliance

Loading...

Loading...