5

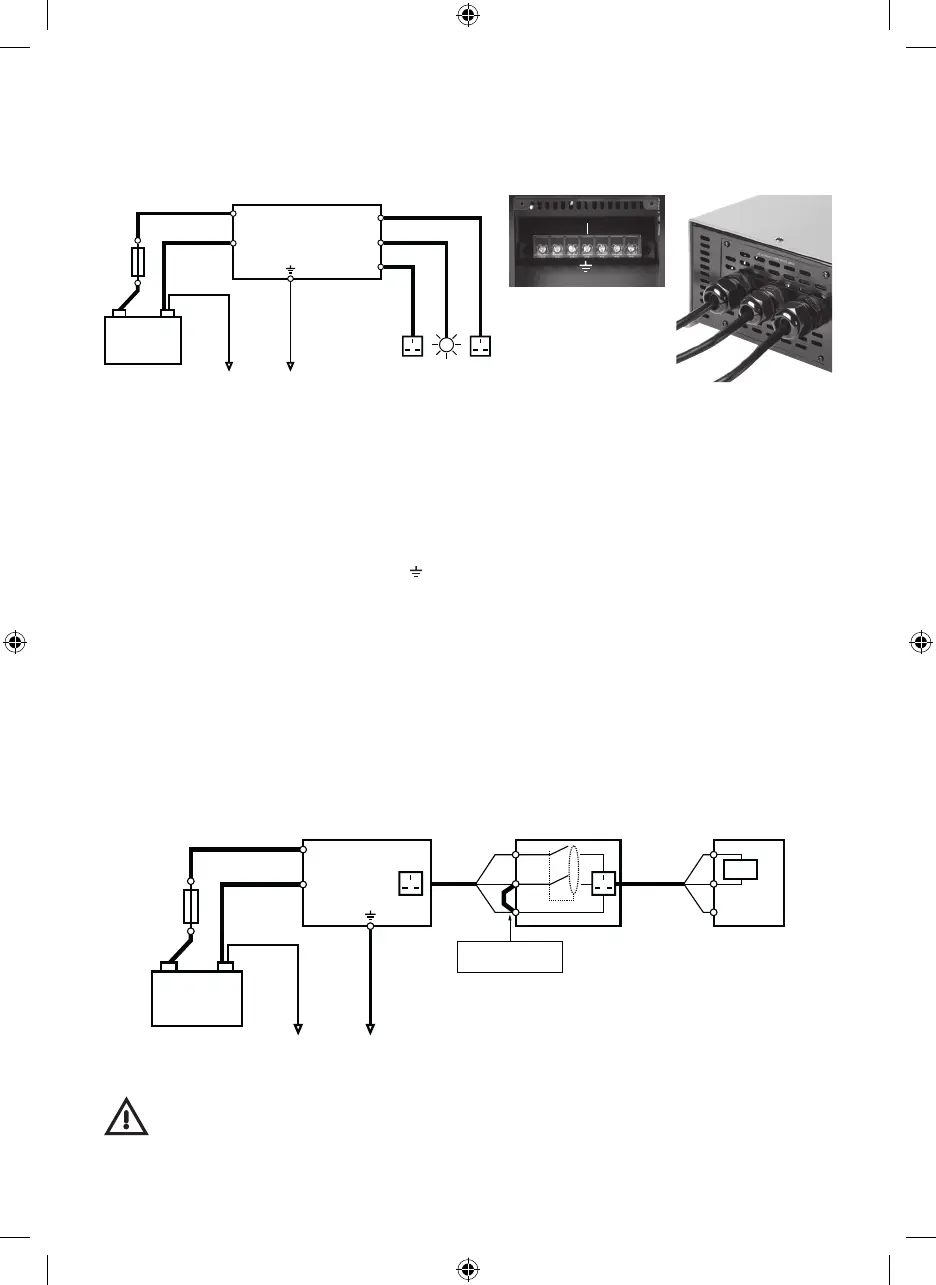

Fig3 – Integral RCD example

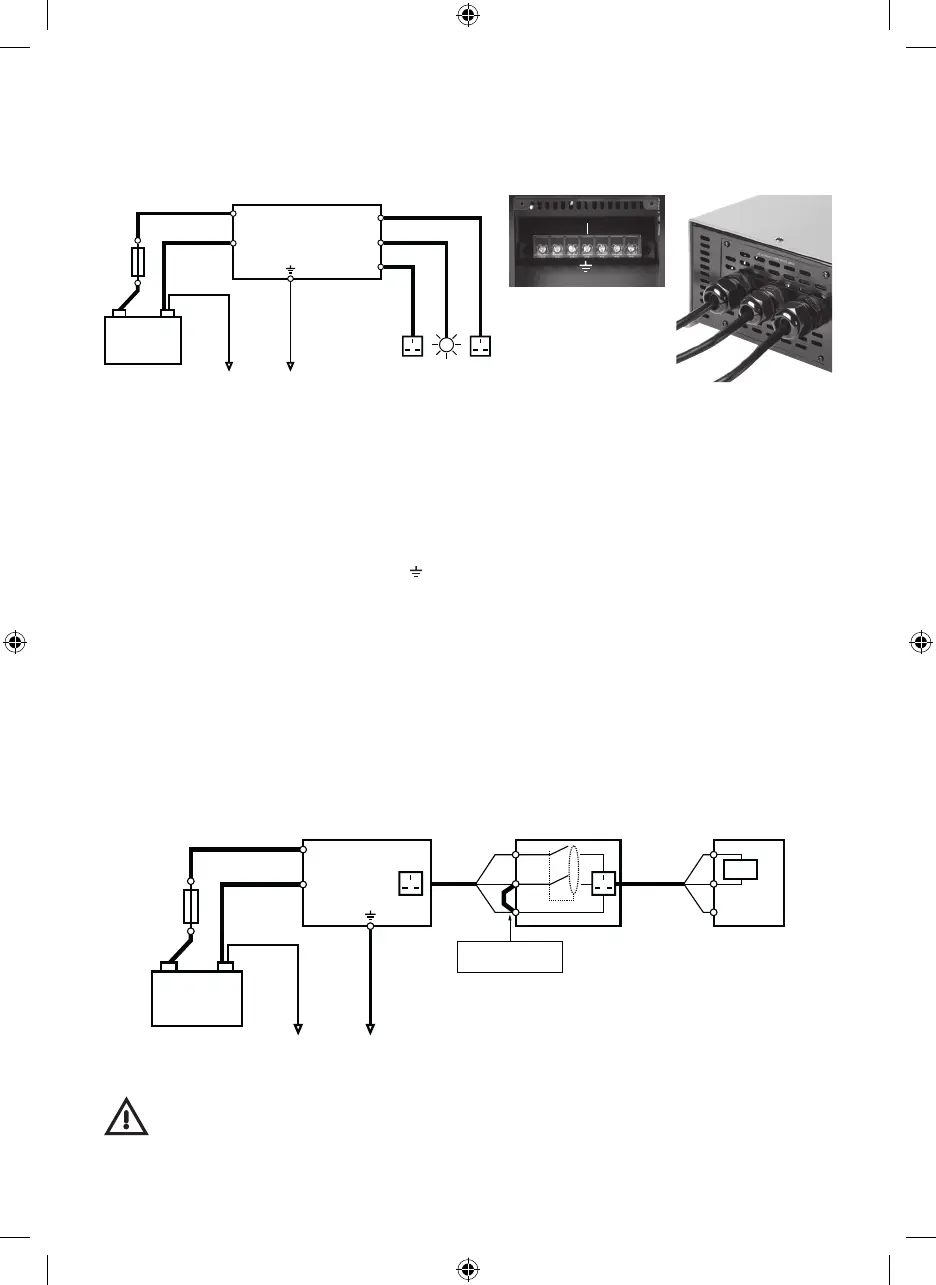

Fig5 – External RCD example

Fig4 – AC terminals Fig5 – Gland fitment

Caution

It is recommended the inverter is wired and tested by a qualified electrician

AC Output Connections - Models with integral RCD

To make installation simpler and provide a more integrated solution, some models are provided with internal

RCD protection and screw terminal connections. Fig3 below shows an example installation

AC Output Connections - models without integral RCD

An RCD device can still be used on models without this feature integrated into the inverter. The diagram

below shows recommended wiring for 230V sockets with an integral RCD. Note:- In order for an RCD device

to trip effectively when used in a vehicle, the neutral output from the inverter should be linked to the

earthing system of the installation. Fig5 below shows a recommended installation

1. Remove 4 x screws from cover plate to allow access to terminals

2. Knockout the required number of apertures and fit supplied cable glands

Outer glands are suitable for up to 2.5mm

2

3-core cable

Central gland is suitable for up to 1.5mm

2

3-core cable

3. Pass cables through gland assemblies then attach to 230V output terminals (see Fig4)

Live(L) = Brown, Neutral(N) = Blue, Earth(

) = Green/Yellow

Note:- It is recommended the supplied fork terminals are used for a more secure connection

4. Re-fit cover plate, fully tighten glands and check cables cannot move (see Fig5)

Inverter

Battery

Inverter

+

–

–

Vehicle

Chassis

Example outputs

Output 1

Output 2

Output 3

230V AC

F1

Inverter

Battery

Inverter

+

+

–

–

Vehicle

Chassis

Appliance230V Socket with integral RCD

Fit N-E link to ensure

RCD will trip

L

N

E

L

N

LOAD

E

F1

Earth

230V AC

Output1

{

{

{

LIVE

LIVE

LIVE

NEUTRAL

NEUTRAL

NEUTRAL

230V AC

Output2

230V AC

Output3

L1 L3N1 N2 N3L2

8pp A5 (PSW) UK Full Handbook v4.indd 5 07/04/2014 09:48

Loading...

Loading...