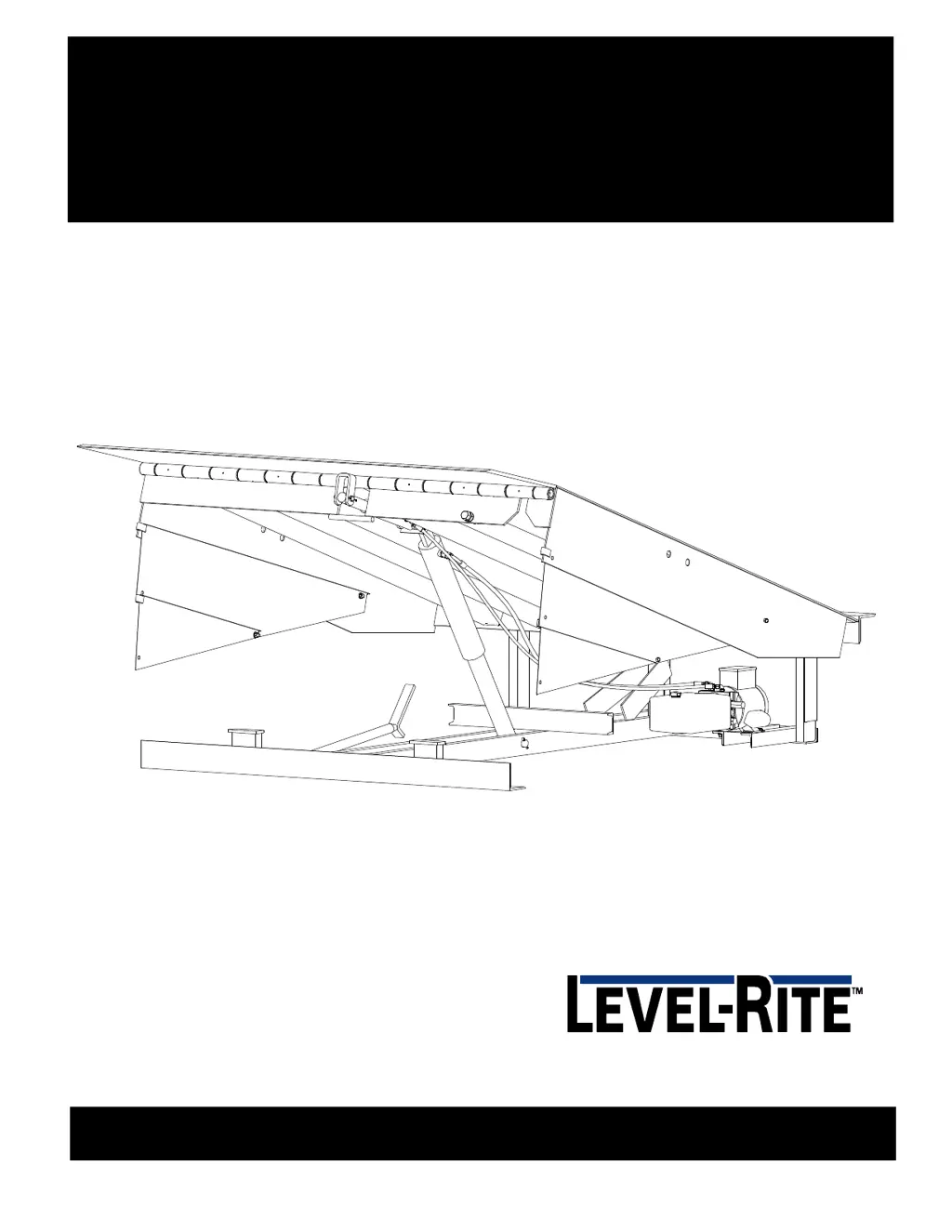

How to fix RITE-HITE LEVEL-RITE HL-800 platform if it does not raise and the motor is not running?

- MmatthewbradshawAug 14, 2025

First, check that the power is connected and that circuit breakers or fuses are not tripped. Ensure the motor and control box are wired per the wiring diagram. Replace the pushbutton operator or contact block if needed. If there is an overload relay, push the RESET button. Compare the customer power supply to the motor and control box ratings. Make sure all wires are correctly and solidly connected in the control box, motor junction box, and pit wall junction box. Check the interconnect limit switch and ARTD cam to ensure they are functional. Lastly, let the motor cool down in case the internal thermal overload has tripped; replace the motor if necessary.