2. WELDING GENERAL CRITERIA

ﻠﻟا ﺮﻴﻳﺎﻌﻣﺔﻣﺎﻌﻟا مﺎﺤ

2./5

2.2.7.

ﻲﻠﻳ ﺎﻤﻣ ﻖﻘﺤﺗ ﺖﻴﺒﺜﺘﻟا ءﺎﻨﺛأ:

ءﻮﻀﻟا رﻮﺤﻤﻟا ةاذﺎﺤﻣ يزاﻮﺘﻟا

ﻲﻠﺤﻤﻟا نﻮﻧﺎﻘﻟا ﻞﺒﻗ ﻦﻣ عﻮﺿﻮﻤﻟا قﺎﻄﻨﻠﻟ ﺎًﻘﻓو ثﻼﺜﻟا تﻻﺎﺤﻟا ﻚﻠﺗ ةﺎﻗﻼﻣ ﺐﺠﻳ

ﺔﻳرﺎﺴﻟا ﺢﺋاﻮﻠﻟاو.

2.2.8

ﺐﺤﺴﻟا ﻂﻐﺿ

P

t

ﻣ ﺎﻬﺳﺎﻴﻗ ﺐﺠﻳةرﻮﺳﺎﻤﻟا ﻊ/تﺎﻄﻣﺎﻘﻟا ﻲﻓ ﺔﺘﺒﺜﻤﻟا ﺔﺒﻴآﺮﺘﻟا.

ﻦﻣ ﻞﻗأ ﺎًﻤﺋاد نﻮﻜﺗ نأ ﺐﺠﻳ

P

1

وP

5

.

SET UP

2.2.1.

Pipes/fittings to be welded

a) They must have

same nominal outside diameter ( D )

same nominal thickness ( s )

D and s must respect the tolerance range established by

the National Legislation and regulations in force.

b) They must have the same product sigma ( σ ).

2.2.2.

Oval-shaped pipes

The oval-shaped percentage

must respect the tolerance range established by the

National Legislation and regulations in force.

2.2.3.

Scratches and notches

The percentage

must respect the tolerance range established by the

National Legislation and regulations in force.

(h = scratch/notch depth).

2.2.4.

Cleaning

Accurately clean the internal and external surfaces of the

ends to be welded.

Use only the cleaning products recommended by the

pipe/fitting producer.

2.2.5.

Rollers

Sustain the pipes with rollers in order to reduce fiction (and

therefore reduce the dragging pressure P

t

).

2.2.6.

Wind plugs

Apply the wind plugs to the ends not being welded in order

to avoid a stack effect.

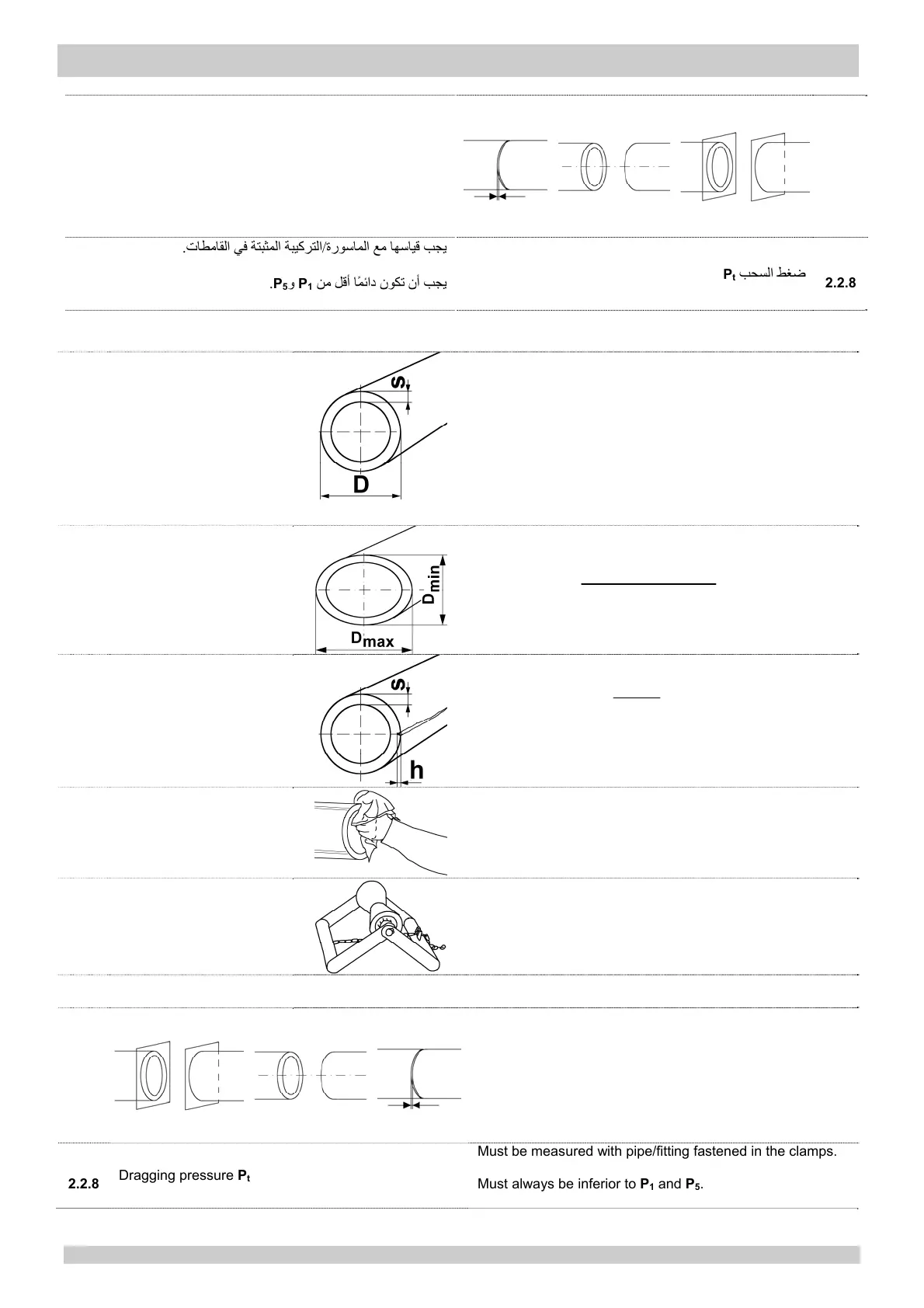

2.2.7.

While fastening check:

Parallelism Axle alignment Light

These three conditions must be met according to the range

established by the National Legislation and regulations in

force.

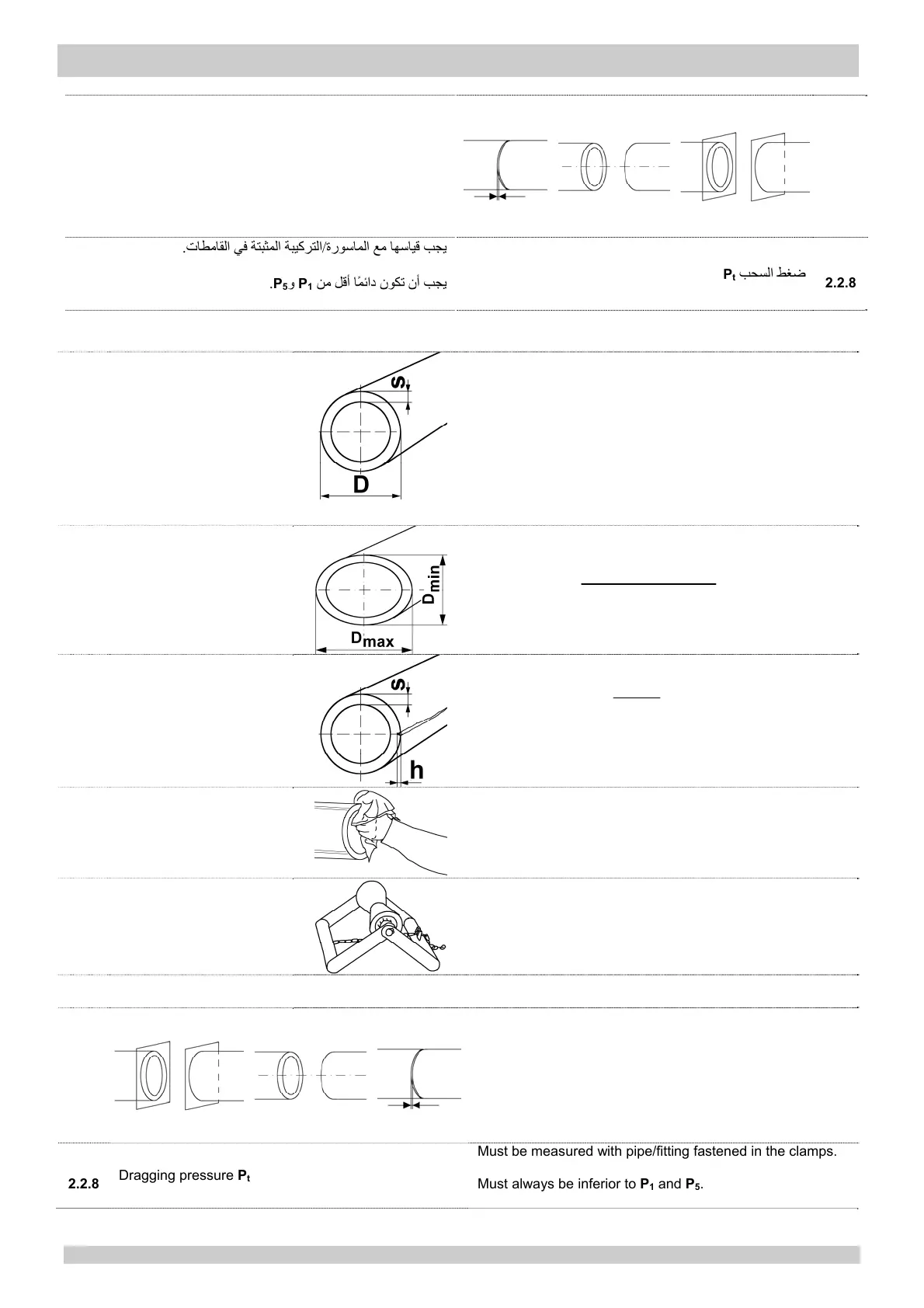

2.2.8

Dragging pressure P

t

Must be measured with pipe/fitting fastened in the clamps.

Must always be inferior to P

1

and P

5

.

x100

D

max

-D

min

D

h

s

x100

Loading...

Loading...