BLOCKSYSTEM FA-FT Pag. 30 REV. 04 10/07

UK

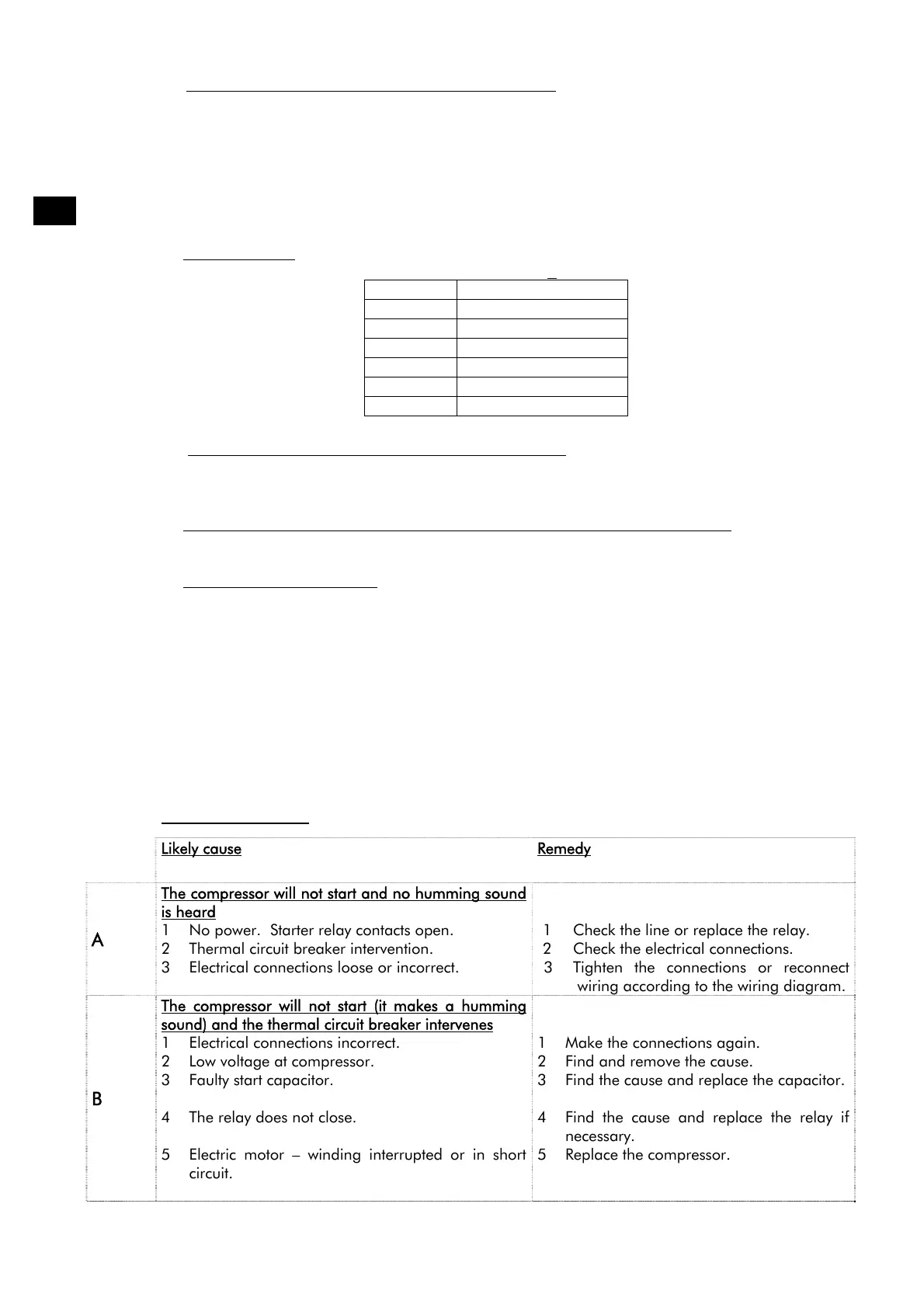

• Plug-in insulating panel kit for FA (supplied separately)

FA 1x250 - COD.99600133

FA 1x300 - COD.99600135

FA 1x350 - COD.99600137

By adding a plug, it is possible to change the assembly method from the standard saddle

version to the plug-in version (mounting instructions will be sent together with the insulating

plug-in panel).

• Different voltage

Es: FAM009Z001

1 230/1/50 Hz

2 400/3/50 Hz

3 110/1/60 Hz

4 220/3/60 Hz

5 220/1/60 Hz

6 460/3/60 Hz

8 230/3/50 Hz

• Additional electronic module for master/slave operation

Used to connect 2 Blocksystem units together in a cold room with the possibility for

synchronised operations (defrost, Blocksystem operation and temperature alarms display)

• Additional electronic module for monitoring ,recording and remote management

Makes it possible to connect the Blocksystem to a remote management system

• Remote management system

Used to monitor and programme the Blocksystem from a PC or data recorder. It makes

advanced management possible (communication via modem or GSM) for all Blocksystem

alarms.

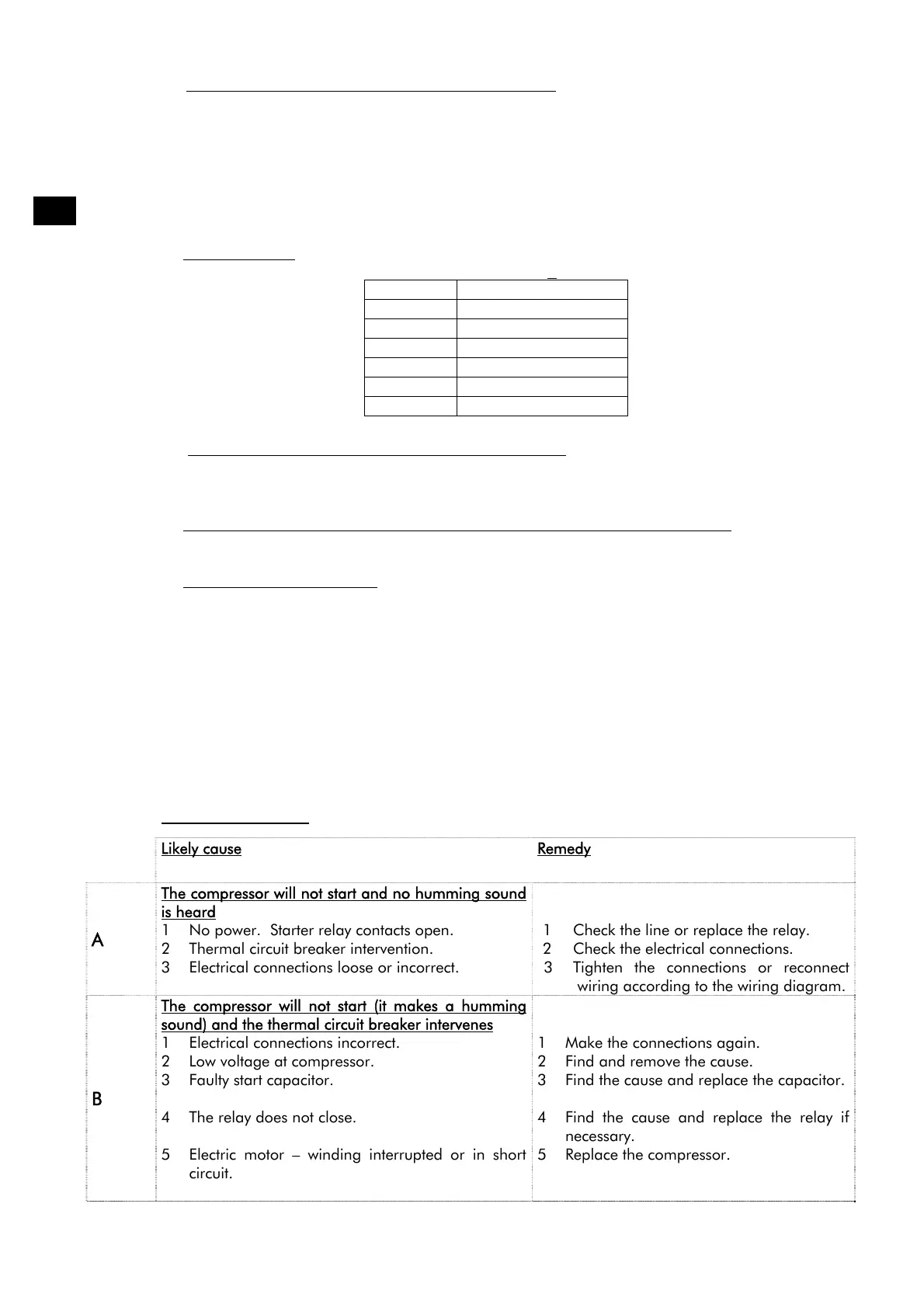

13.

TROUBLESHOOTING

Likely cause Remedy

A

The compressor will not start and no humming sound

is heard

1 No power. Starter relay contacts open.

2 Thermal circuit breaker intervention.

3 Electrical connections loose or incorrect.

1 Check the line or replace the relay.

2 Check the electrical connections.

3 Tighten the connections or reconnect

wiring according to the wiring diagram.

B

The compressor will not start (it makes a humming

sound) and the thermal circuit breaker intervenes

1 Electrical connections incorrect.

2 Low voltage at compressor.

3 Faulty start capacitor.

4 The relay does not close.

5 Electric motor – winding interrupted or in short

circuit.

1 Make the connections again.

2 Find and remove the cause.

3 Find the cause and replace the capacitor.

4 Find the cause and replace the relay if

necessary.

5 Replace the compressor.

Loading...

Loading...