ST-SP Pag. 59 Rev 02 05/13

UK

8

8

.

.

F

F

a

a

u

u

l

l

t

t

s

s

s

s

e

e

a

a

r

r

c

c

h

h

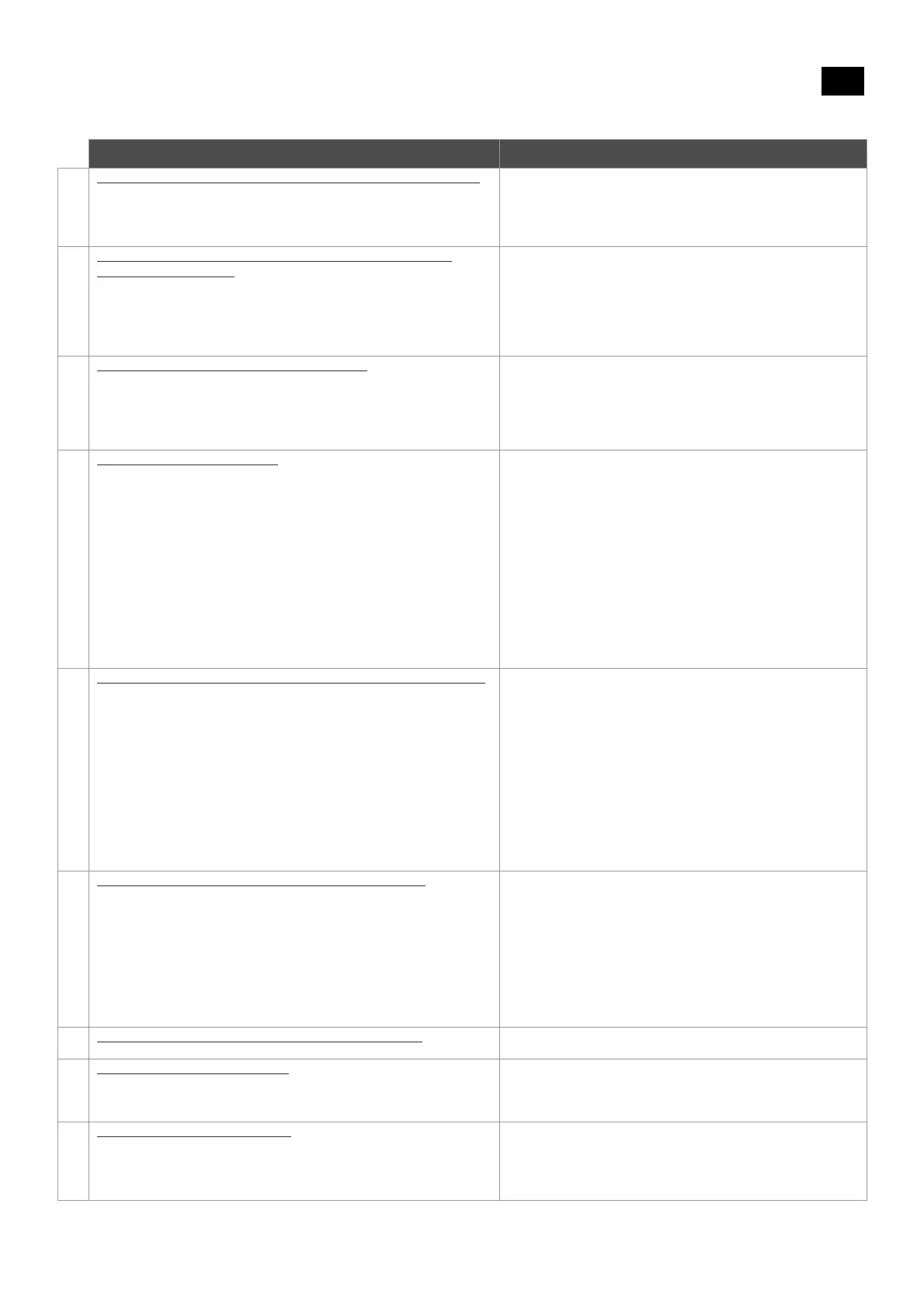

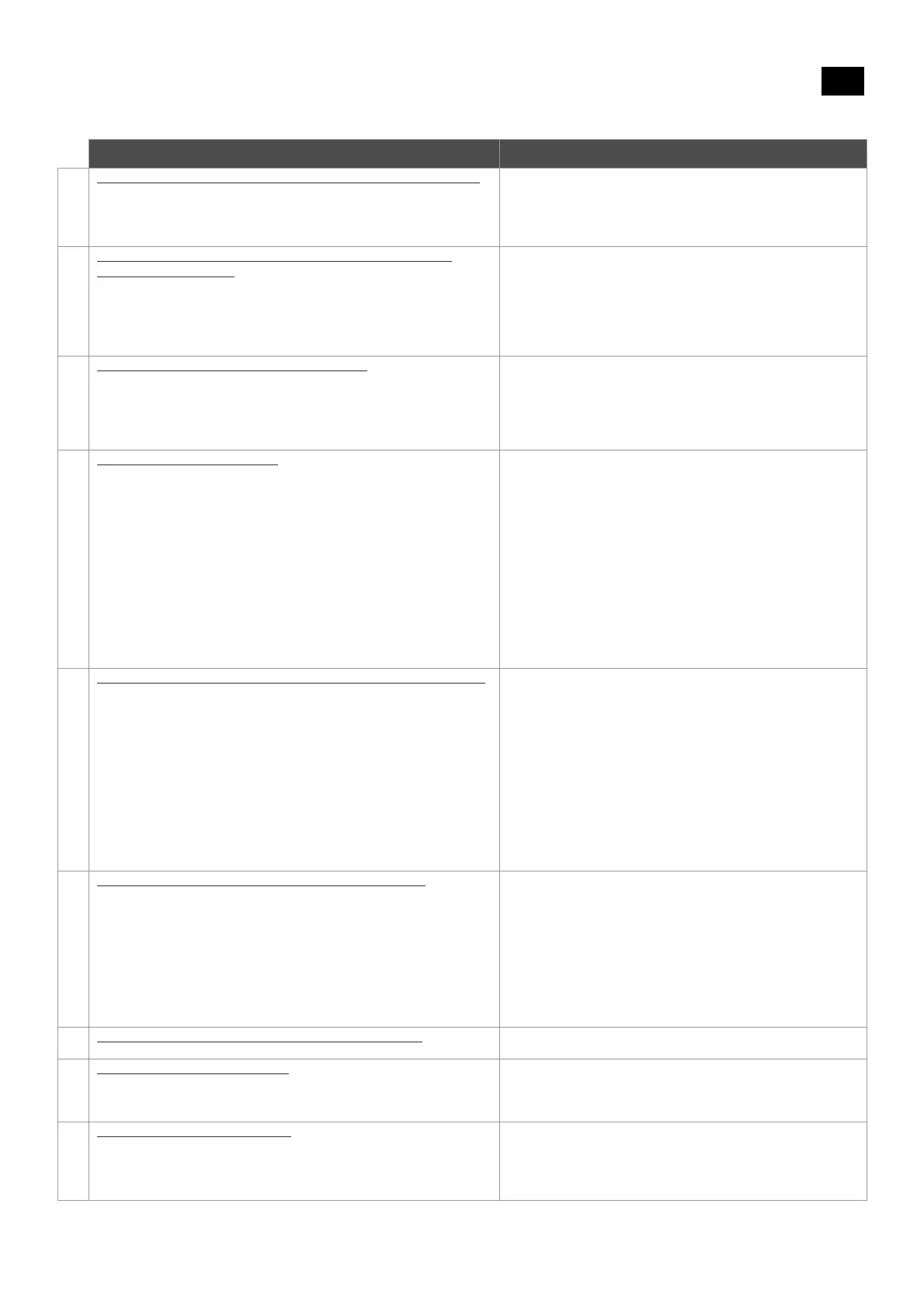

POSSIBLE CAUSES SOLUTIONS

A

The compressor does not start and does not release a humming sound

1 Lack of voltage. Start-up relay with open contacts.

2 Thermal cut-off intervenes.

3 Loose electrical connections or incorrect electrical connections.

1 Check the line or replace the relay.

2 Re-check the electrical connections.

3 Tighten or re-do the connections in accordance to the

wiring diagram.

B

The compressor does not start (releases humming sound) and the

thermal cut-off intervenes

1 Incorrect electrical connections.

2 Low voltage supply to the compressor.

3 Defective start-up of the condenser.

4 Relay does not close.

5 Winding of the electrical motor interrupted or in short-circuit.

1 Re-do the connections.

2 Identify the cause and eliminate it .

3 Identify the cause and replace the condenser.

4 Identify the cause and replace the relay if necessary.

5 Replace the compressor.

C

The compressor starts but the relay does not open

1 Incorrect electrical connections.

2 Low voltage supply to the compressor.

3 Relay blocked in closed position.

4 Excessive discharge pressure.

5 Winding of the electrical motor interrupted or in short-circuit.

1 Check the electrical circuit.

2 Identify the cause and eliminate it.

3 Identify the cause and eliminate it .

4 Identify the cause and replace the relay if necessary.

5 Replace the compressor.

D

Intervention of the thermal cut-off

1 Low voltage supply to the compressor (imbalanced phases on tri-

phase motors).

2 Defective thermal cut-off.

3 Defective running condenser.

4 Excessive discharge pressure.

5 Suction pressure too high.

6 Compressor overheated, hot return gas.

7 Winding of the compressor motor in short-circuit.

1 Identify the cause and eliminate it.

2 Check its characteristics and replace it if necessary.

3 Identify the cause and eliminate it .

4 Check the ventilation and any possible restrictions or

obstructions in the system circuit.

5 Check the sizing of the system. Replace the condensing

unit with a more powerful one, if necessary.

6 Check the refrigerant load; repair the potential loss and

add gas if necessary.

If the semi-machine does not have a safety valve, the load of

refrigerant gas must be lower than 10 kg.

7 Replace the compressor.

E

The compressor starts and circulates, with short-spanned function cycles

1 Thermal cut-off.

2 Thermostat.

3 Intervention of the high pressure meter, due to the insufficient

cooling of the condenser.

4 Intervention of the high pressure meter, due to the excessive load

of refrigerant gas.

5 Intervention of the low pressure meter, due to the scarce load of

refrigerant gas.

6 Intervention of the low pressure meter, due to the restriction or

clogging of the expansion valve.

1 See previous point (thermal cut-off intervention).

2 Small differential; correct adjustment .

3 Check that the motorized ventilator functions correctly or

clean the condenser.

4 Reduce the refrigerant load.

5 Repair the loss and add refrigerant gas.

If the

PARTLY COMPLETED MACHINERY does not have a safety valve, the

load of refrigerant gas must be lower than 10 kg.

6 Replace the expansion valve.

F

The compressor functions uninterruptedly or for long periods

1 Poor load of refrigerant gas.

2 Thermostat contacts blocked in closed position.

3 System insufficiently sized in function of the load.

4 Excessive load to cool or insufficient insulation.

5 Evaporator covered with ice.

6 Restriction in the system circuit.

7 Condenser clogged.

1 Repair the loss and add refrigerant gas.

If the

PARTLY COMPLETED MACHINERY does not have a safety valve, the

load of refrigerant gas must be lower than 10 kg.

2 Replace the thermostat.

3 Replace the system with a more powerful one.

4 Reduce the load and improve insulation, if possible.

5 Defrost.

6 Identify the resistance and eliminate it .

7 Clean the condenser.

G

Running condenser damaged, interrupted, or in short-circuit

1 Incorrect running condenser.

1 Replace the condenser with the correct type.

H

Start-up relay defective or burnt out

1 Incorrect relay.

2 Relay assembled incorrectly .

3 Incorrect running condenser.

1 Replace with the correct relay.

2 Reassemble the relay in the correct position.

3 Replace the condenser with the correct type.

I

Compartment temperature too high

1 Thermostat regulated too high.

2 Expansion valve under-sized.

3 Evaporator under-sized.

4 Insufficient air circulation.

1 Regulate correctly.

2 Replace the expansion valve with a suitable one.

3 Replace it increasing the surface of the evaporator.

4 Improve air circulation.

Loading...

Loading...