ST-SP Pag. 45 Rev 02 05/13

UK

4.2.1 Lifting

DANGER:

all lifting operations must be carried out under the direct supervision of a qualified mechanical

serviceman or technician appointed by the Manufacturer.

The lifting and subsequent positioning of the machine can be carried out by any suitable means ensuring effective and safe

handling (for example a hoist with a harness system).

To correctly carry out lifting operations, follow the instructions below.

Never use two lifting means simultaneously.

Never stand under suspended loads.

If steel wire ropes are used, always use a correct eye with the lifting hook.

If steel wire ropes are used, be careful not to create folds with a radius of curvature lesser than the one of the eyes at the end

of the rope.

Use ropes of suitable length so that the angle between the ropes and the horizontal plane is always greater than 45°.

4.2.2 Machine movement

For reduced distances, as in the case of transport to the assembly or storage locations of the machine, it is necessary to use lifting

equipment (for example, forklift and hoists) suitable for the dimensions and weight of the machine.

ATTENTION:

during all these operations follow the precautions necessary to avoid knocking and tipping over,

moving the machine in a manner not to loose balance.

DANGER:

ensure there are no unauthorised staff near the zone where the lifting, movement and unloading

operations take place and always keep a safe distance.

4.3 Installation

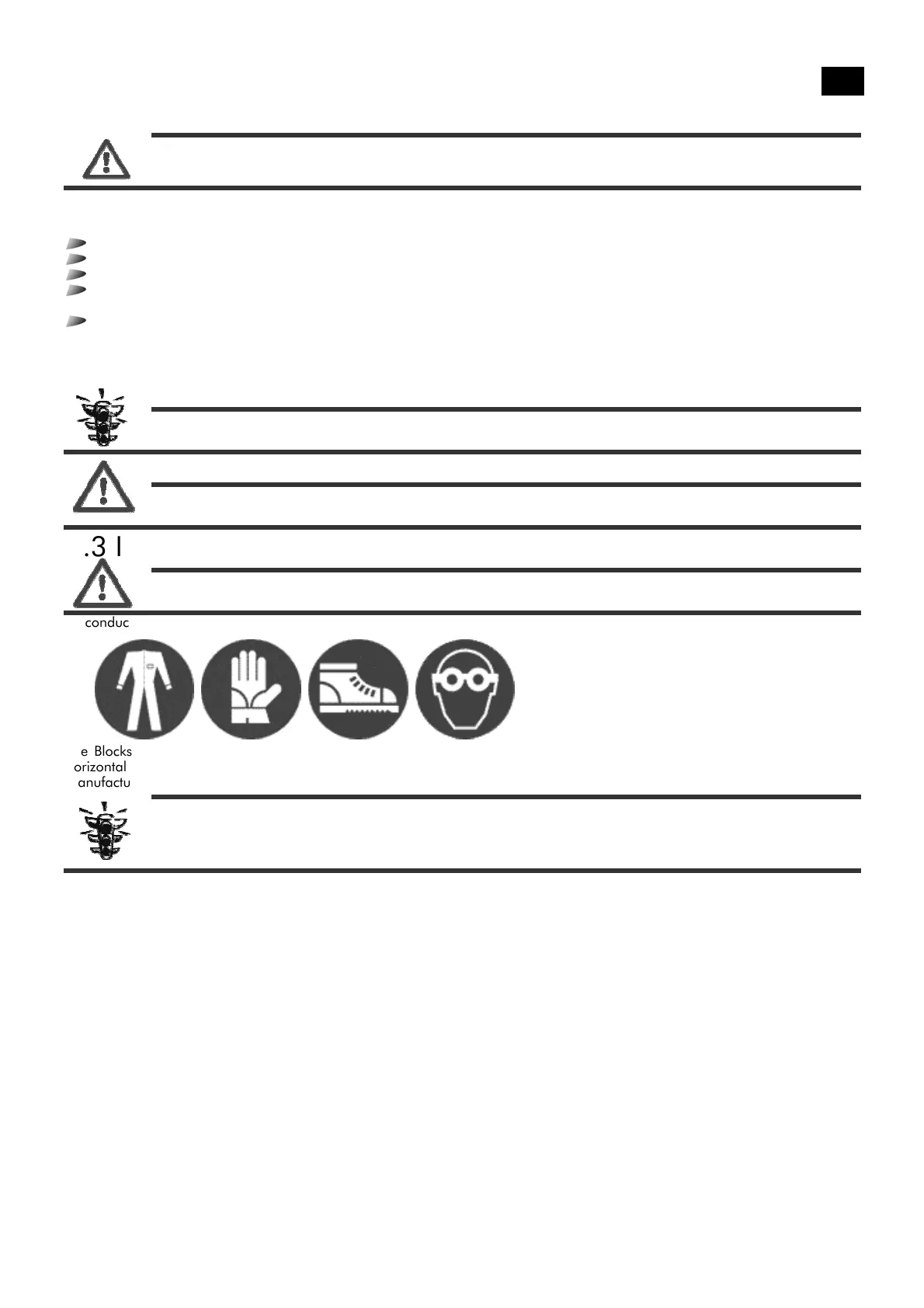

DANGER:

the Manufacturer cannot be held responsible for any damage to property and/or people arising from

improper operations carried out by unqualified, untrained or unauthorized staff.

To conduct the task in question, the following Individual Protection Devices are necessary:

The Blocksystem ST-SP must be installed in well ventilated areas. As well as this the Blocksystems ST must only installed on a

horizontal surface while the Blocksystem SP on a vertical one. In the case of any other type of installation contact the

manufacturer.

ATTENTION:

before installation it is necessary to develop a plan for refrigeration system defining: a) all components

of the system, including the condensing unit, the evaporator, the distribution, the thermostatic valve,

the front cell electric panel, the size of the pipes, any safety devices, etc.. b) the location of the plant; c)

the path of the pipes.

Leave enough space around the machine to carry out maintenance operations safely.

Also during installation leave enough space around the machine to carry out maintenance operations safely.

For correct machine operation, the following minimum thickness of the cell walls are recommended (insulating polyurethane):

MBP and HBP cell insulation thickness 60 mm; LBP cell insulation thickness 100 mm.

4.3.1 Blocksystem ST-SP Installation Methods

To install the machine follow the procedure below:

1. Raise the machine by a suitable means, with correct lifting hooks.

2. For the Blockystem ST, fix the condensation unit on the floor or ceiling with the 4 screws as shown in Picture 3. For the

Blocksystem SP, fix the condensation unit to the vertical wall with the 4 screws as shown in Picture 4, always leaving a

minimum ground clearance of 600 mm.

3. Continue by fixing the evaporator inside the cell with the 4 steel bolts (Picture 3 for ST picture 4 for SP).

4. Lengthen the discharge pipe of the evaporator tank with a rubber hose (minimum temperature resistance: 90 °C) to the

outside of the cell to create a siphon (Picture 3 for ST and Picture 4 for SP). N.B. in the case of the MBP and LBP models insert

the discharge resistance into the hose.

5. Make a hole in the wall of the cell (Picture 3 for ST and Picture 4 for SP) to pass the feeding and aspiration pipes and water

drain hose.

6. Make a hole to pass the following cables: power, evaporator fan, discharge resistance, defrost heater, and cell light.

Loading...

Loading...