5. OPERATION

IMR02L04-E3

5-25

Caution for using the Autotuning (AT)

When a temperature change (UP and/or Down) is 1 C or less per minute during AT, AT may not be finished

normally. In that case, adjust the PID values manually. Manual setting of PID values may also be necessary

if the set value is around the ambient temperature or is close to the maximum temperature achieved by the

load.

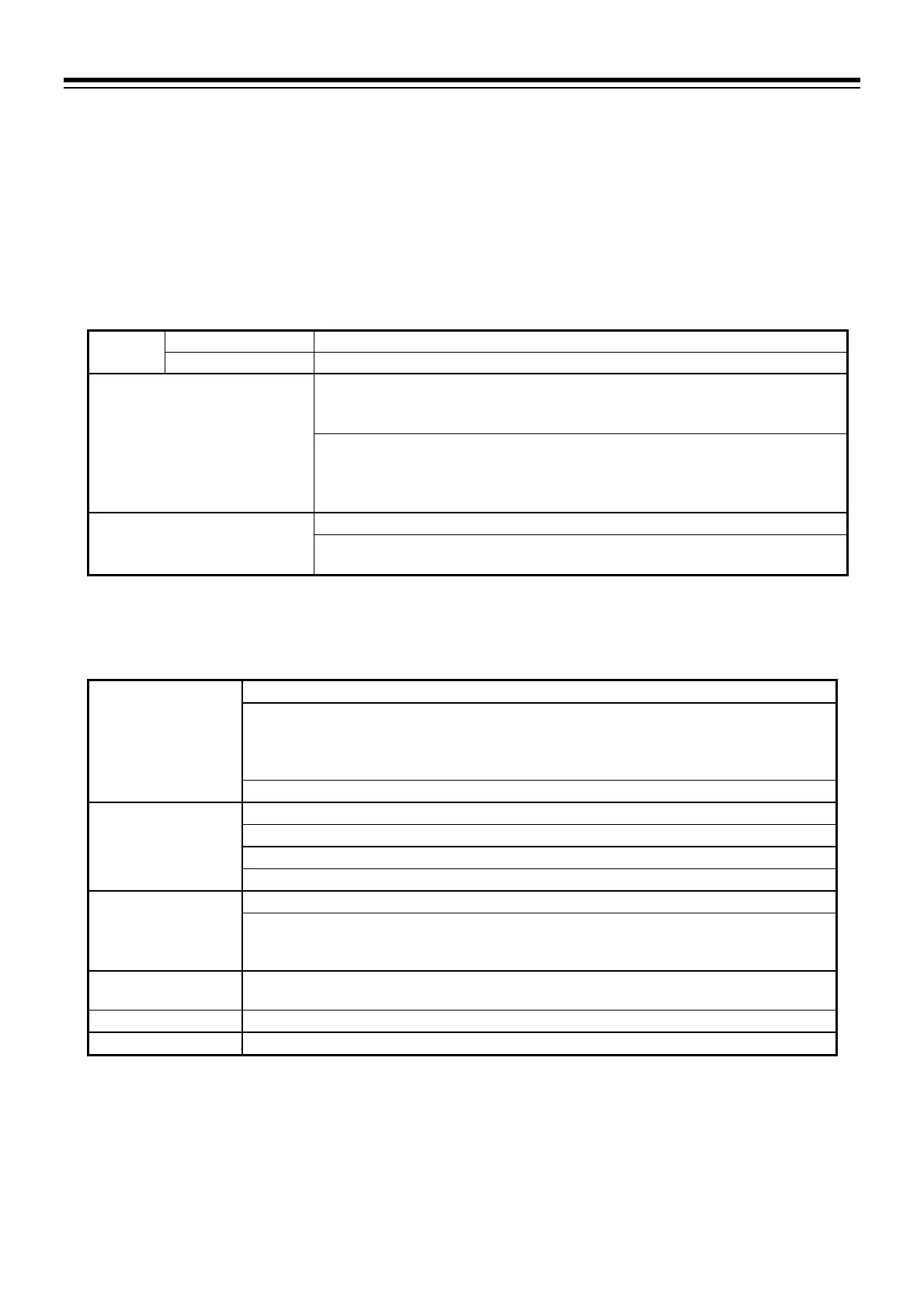

Requirements for AT start

Start the AT when all following conditions are satisfied:

To start AT, go to

PID/AT transfer [ATU] in Operation mode.

Operation

mode state

Operation mode transfer Program control mode or Fixed set point control mode

PID/AT transfer PID control (State before starting AT)

Parameter setting

PID control, Position proportioning PID control:

・Output limiter high (MV1) 0.1 %, Output limiter low (MV1) 99.9 %

・Output value with AT turned on 0.1 %, Output value with AT turned off 99.9 %

Heat/Cool PID control:

・Output limiter high (MV1) 0.1 %, Output limiter low (MV1) 99.9 %

・Output limiter high (MV2) 0.1 %, Output limiter low (MV2) 99.9 %

・Output value with AT turned on +0.1 %, Output value with AT turned off

0.1 %

Input value state

The Measured value (PV) is not underscale or over-scale.

Input error determination point (high) Measured value (PV) Input error

determination point (low)

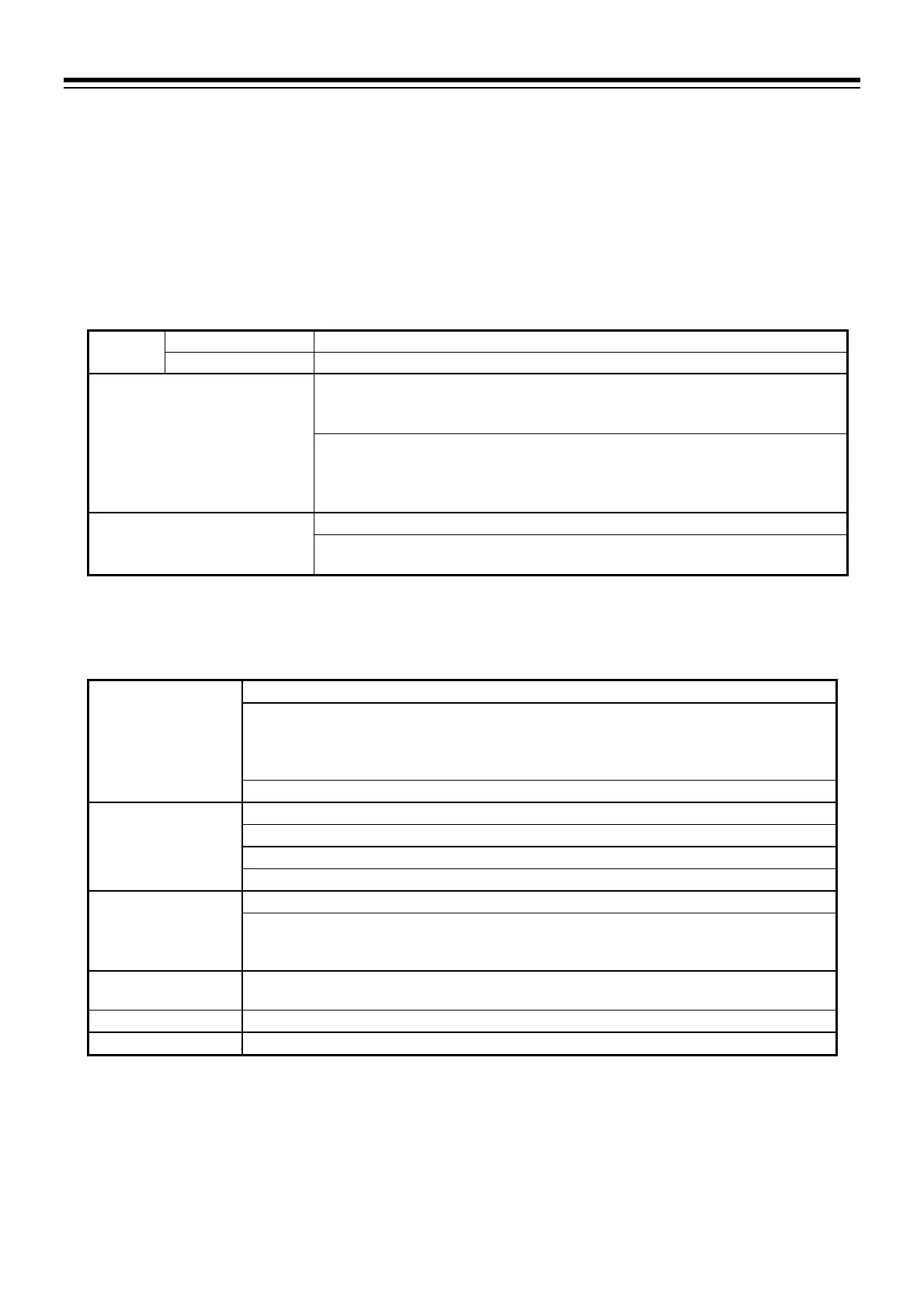

Requirements for AT cancellation

If the AT is canceled according to any of the following conditions, the controller immediately changes to

PID control. The PID values will be the same as before AT was activated.

When the Operation

mode is transferred

When the operation mode is changed to the Reset mode (RESET).

When AT is conducted in the Program control mode (RUN):

When switching to the Fixed set point control mode (FIX) or the Manual control mode (MAN)

When AT is conducted in the Fixed set point control mode (FIX):

When switching to the Program control mode (RUN) or the Manual control mode (MAN)

When the PID/AT transfer is changed to the PID control.

When the parameter is

changed

When changing Segment level or Set value (SV)

When the PV bias, the PV digital filter, or the PV ratio is changed.

When changing Output limiter high or low

When performing Step function

When the input value

becomes abnormal

When the Measured value (PV) goes to underscale or over-scale.

When the Measured value (PV) goes to input error range.

(Measured value (PV) Input error determination point (high) or Input error determination point

(low) Measured value (PV))

When the AT exceeded

the execution time

When the AT does not end in nine hours after AT started

Power failure When the power failure of more than 20 ms occurs.

Instrument error When the instrument is in the FAIL state.

Where to store computed PID value by regular Autotuning (AT)

For Program control mode (RUN):

AT-computed PID values are stored in PID memory group being set for each segment.

For Fixed set point control mode (FIX):

AT-computed PID values are stored in PID memory group being set by PID memory group number

[PID.GR] in the Fixed set point control mode (FIX).

Loading...

Loading...