2)

0

3)

4)

5)

Remove flywheel

from

crankshaft.

Apply

a

socket wrench over the flywheel

nut and give the wrench

a

sharp blow with

a

soft hammer. Remove nut and spring

washer. (EY14:

12

mm nut/EY18-3, EY23,

EY25-2, EY27-2: 14 mm nut)

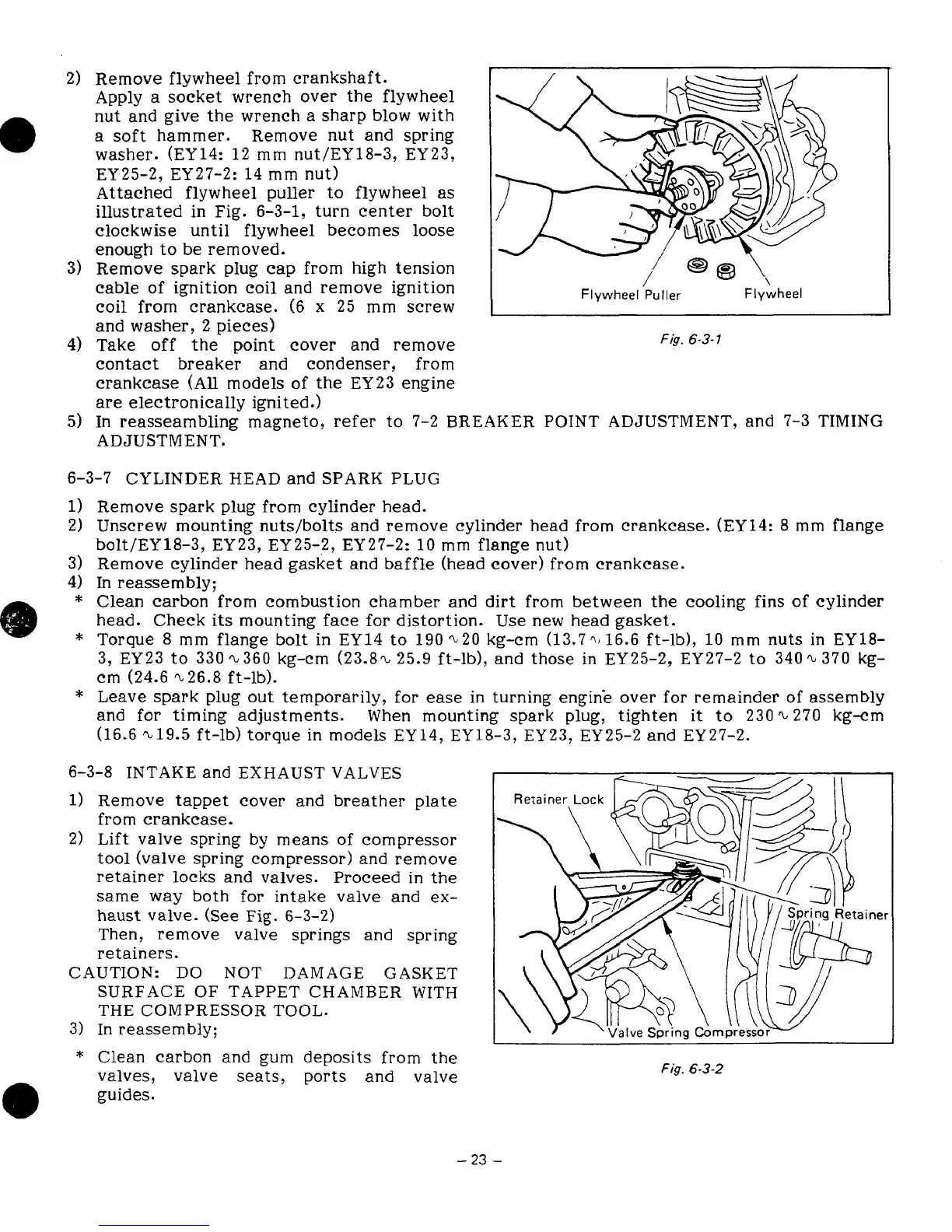

Attached flywheel puller

to

flywheel

as

illustrated in Fig. 6-3-1, turn center

bolt

clockwise until flywheel becomes

loose

enough

to

be

removed.

Remove spark plug cap from high tension

cable

of ignition

coil

and remove ignition

coil from crankcase.

(6

x

25 mm screw

and washer,

2

pieces)

Take off the point cover and remove

contact breaker and condenser, from

crankcase (All models of the EY23 engine

are

electronicallv ignited.)

I

Flywheel Puller Flywheel

Fig.

6-3-

7

In reasseambling magneto, refer

to

7-2 BREAKER POINT ADJUSTMENT, and 7-3 TIMING

ADJUSTMENT.

"

6-3-7 CYLINDER HEAD and SPARK PLUG

1)

Remove spark plug from cylinder head.

2)

Unscrew mounting nuts/bolts and remove cylinder head from crankcase. (EY14:

8

mm flange

3) Remove cylinder head gasket and baffle (head cover) from crankcase.

4) In reassembly;

bolt/EY18-3, EY23, EY25-2, EY27-2:

10

mm flange nut)

*

Clean carbon from combustion chamber and dirt from between the cooling fins

of

cylinder

head. Check

its

mounting face for distortion. Use new head gasket.

*

Torque

8

mm flange bolt in EY14

to

190 2.20 kg-cm (13.7.> 16.6 ft-lb),

10

rnm

nuts in EY18-

3,

EY23 to 330

%

360 kg-cm (23.8% 25.9 ft-lb), and those in EY25-2, EY27-2

to

340

%

370 kg-

cm (24.6 -26.8 ft-lb).

*

Leave spark plug out temporarily, for

ease

in turning engine over for remainder

of

assembly

and

for

timing adjustments. When mounting spark plug, tighten

it

to

230

Q,

270 kg-cm

(16.6 %19.5 ft-lb) torque in models EY14, EY18-3, EY23, EY25-2 and EY27-2.

6-3-8 INTAKE and EXHAUST VALVES

1)

Remove tappet cover and breather plate

from crankcase.

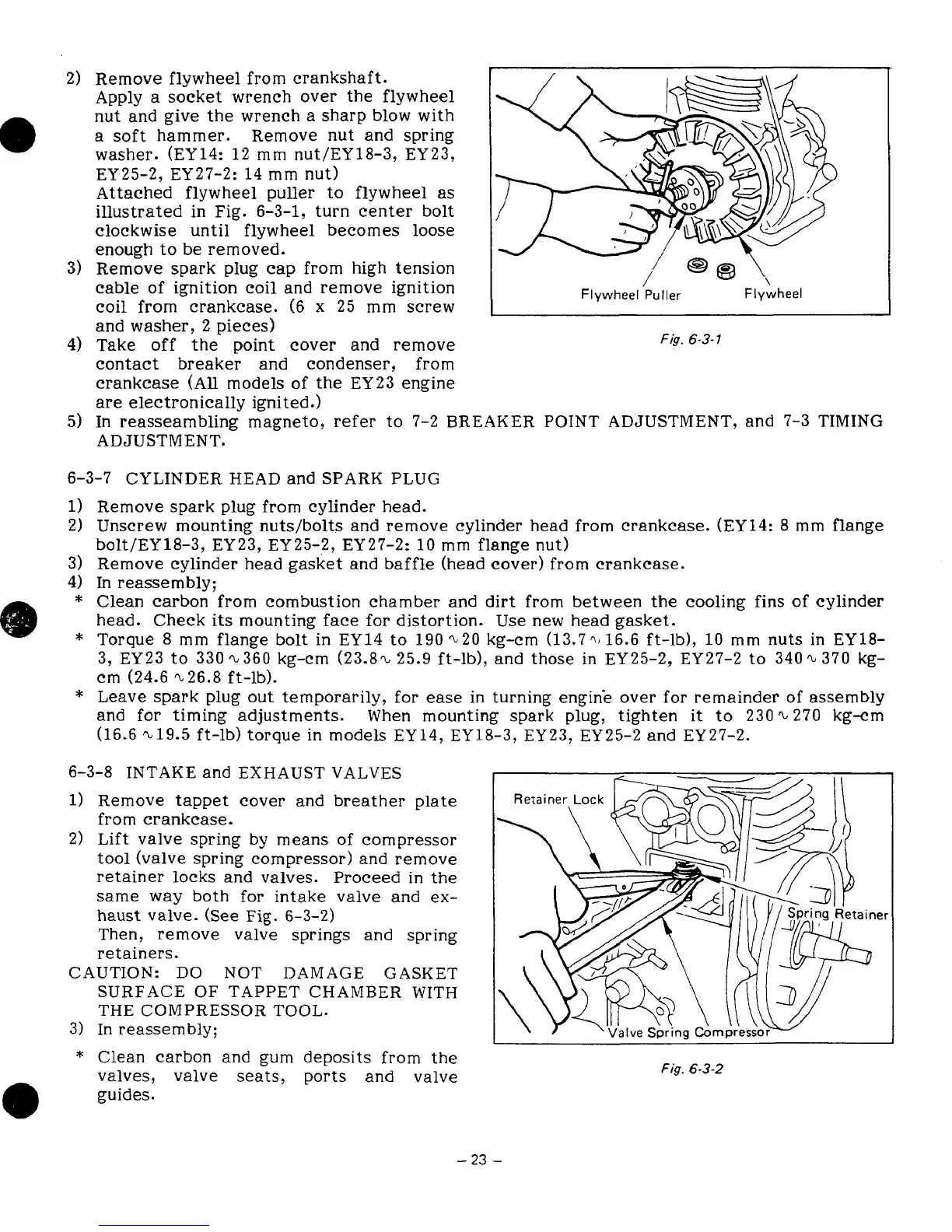

2) Lift valve spring

by

means

of

compressor

tool (valve spring compressor) and remove

retainer locks and valves.

Proceed

in

the

same way both

for

intake valve and ex-

haust valve.

(See

Fig.

6-3-2)

Then, remove valve springs and spring

retainers.

CAUTION:

DO

NOT DAMAGE GASKET

SURFACE

OF

TAPPET CHAMBER WITH

THE COMPRESSOR

TOOL.

3)

In

reassembly;

*

Clean carbon and gum deposits from the

I

Fig.

6-3-2

-

23

-

Loading...

Loading...