7.

MAGNETO

7-1

MAGNETO

The spark for ignition

is

furnished by

a

magneto in models EY14,

EY18-3,

EY23, EY25-2 and

EY27-2. In these models, magnetos manufactured

by

KOKUSAN DENKI K.K.

are

used.

(The

model

EY23

is

based on noncontact ignition system.)

The

magneto consists

of

a

flywheel, ignition coil, and breaker assembly (including condenser),

of

which flywheel

is

mounted on crankshaft and ignition

coil

and

breaker

assembly

are

mounted in

crankcase directly.

7-2

BREAKER POINT ADJUSTMENT

The

breaker points, which

are

mounted in

the

crankcase inside the flywheel should

be

checked twice

a

season

or

whenever the

ignition

spark

becomes weak. If

there

is

evidence

of

pitting

or

pyramidding,

the

breaker points must

be

corrected, and then

it

becomes necessary

to

readjust

the

gap

to

its

proper clearance. (0.35 mm, 0.014 inch)

The

normal

breaker

point opening

is

0.35

mm

at

full

separation. Since

the

spark timing

of

23O

is

regulated by

the

point opening, use

a

timing

light

to

obtain an accurate

spark

advance.

To

adjust

breaker

point opening, remove

starting pulley, blower housing and flywheel

from

the

engine and proceed

as

follows.

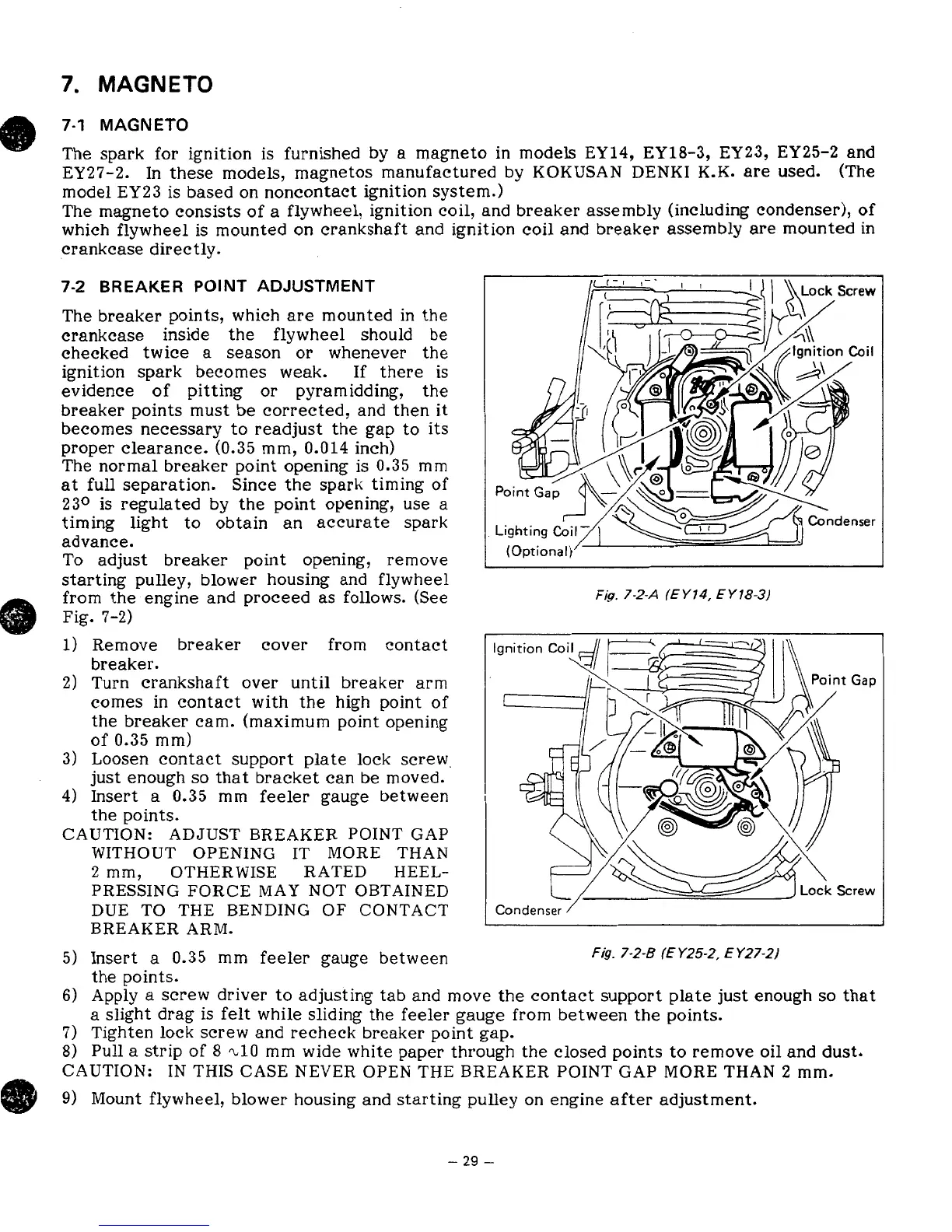

(See

Fig.

7-2)

1)

Remove

breaker

cover

from

contact

breaker.

2)

Turn crankshaft over until

breaker

arm

comes in contact with

the

high

point

of

the

breaker cam. (maximum point opening

of

0.35

mm)

3)

Loosen contact support plate

lock

screw,

just enough

so

that

bracket

can

be

moved.

4) Insert

a

0.35

mm feeler gauge between

the

points.

CAUTION: ADJUST BREAKER POINT GAP

WITHOUT OPENING

IT

MORE THAN

2

mm,

OTHERWISE RATED

HEEL-

PRESSING FORCE

MAY

NOT OBTAINED

DUE TO

THE

BENDING OF CONTACT

BREAKER ARM.

5) Insert

a

0.35

mm feeler gauge between

the points.

I

Fig.

7-2-A

(EY74, EY

18-31

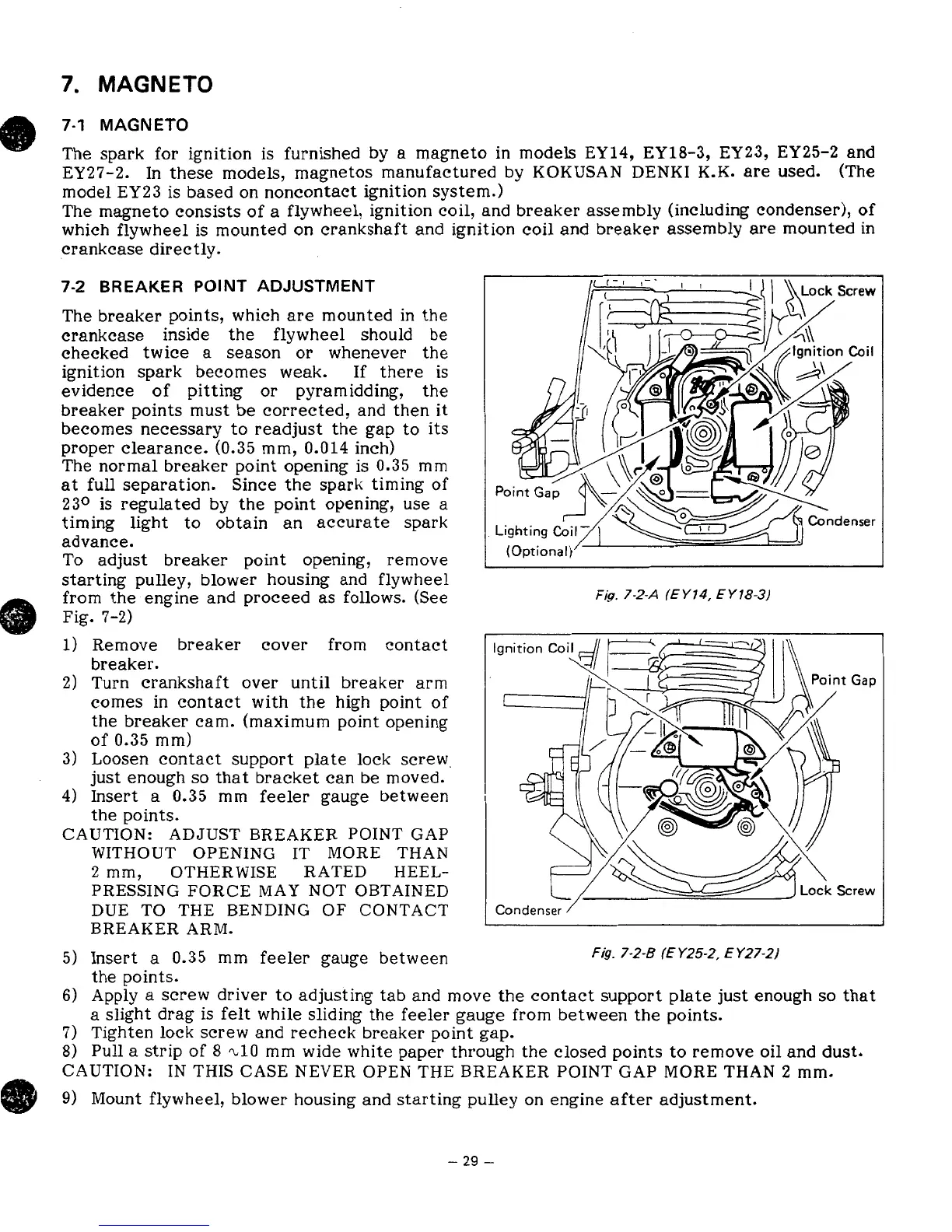

Fig.

7-2-6

(E

Y25-2,

E

y27-21

6)

Apply

a

screw driver

to

adjusting

tab

and move

the

contact support plate just enough

so

that

7)

Tighten

lock

screw and

recheck

breaker

point

gap.

8)

Pull

a

strip

of

8

%lo

rnm wide white paper through

the

closed

points

to

remove oil and dust.

CAUTION: IN THIS CASE NEVER OPEN THE BREAKER POINT

GAP

MORE

THAN 2

mm.

9)

Mount flywheel, blower housing and starting pulley on engine after adjustment.

a

slight

drag

is

felt while sliding

the

feeler gauge

from

between

the

points.

-

29

-

Loading...

Loading...