Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 63

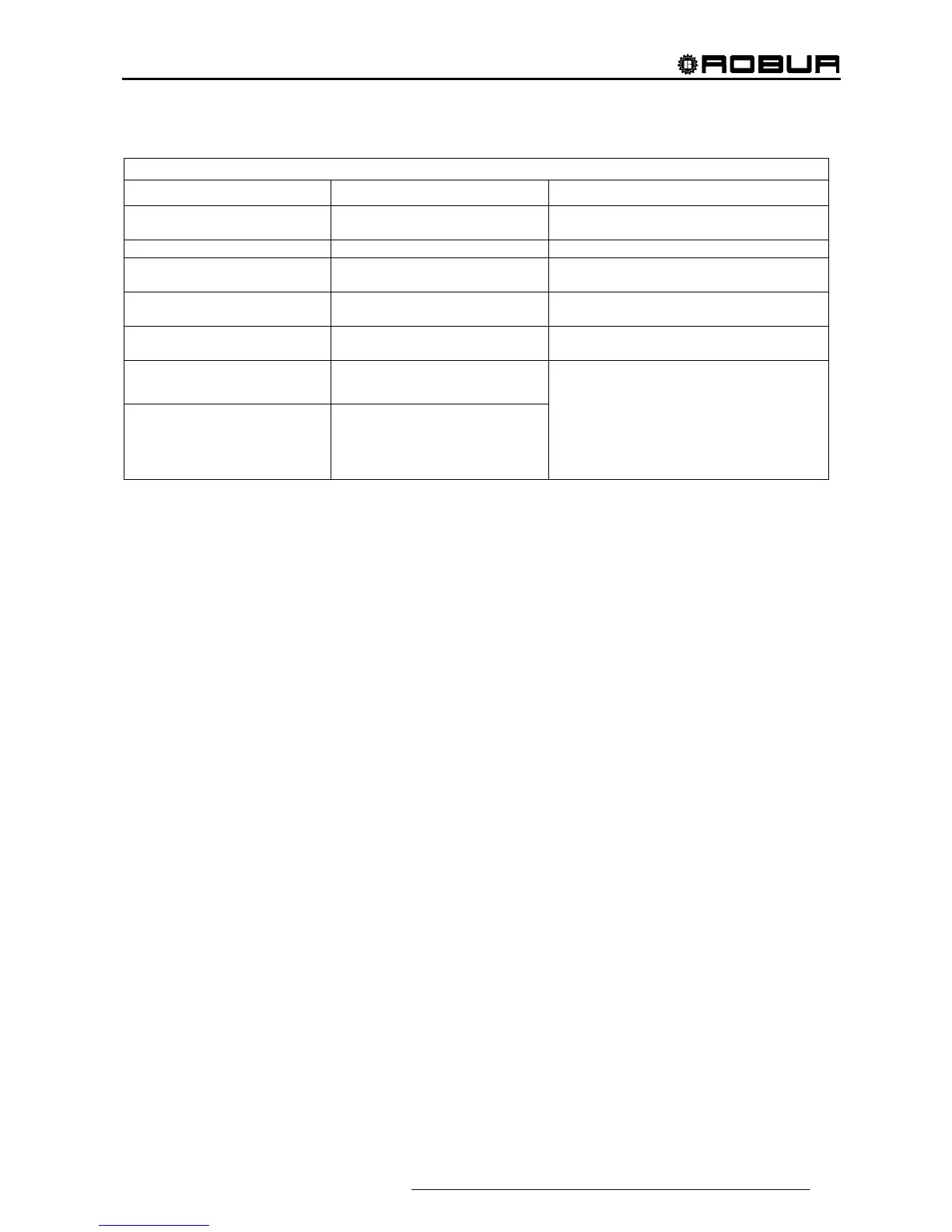

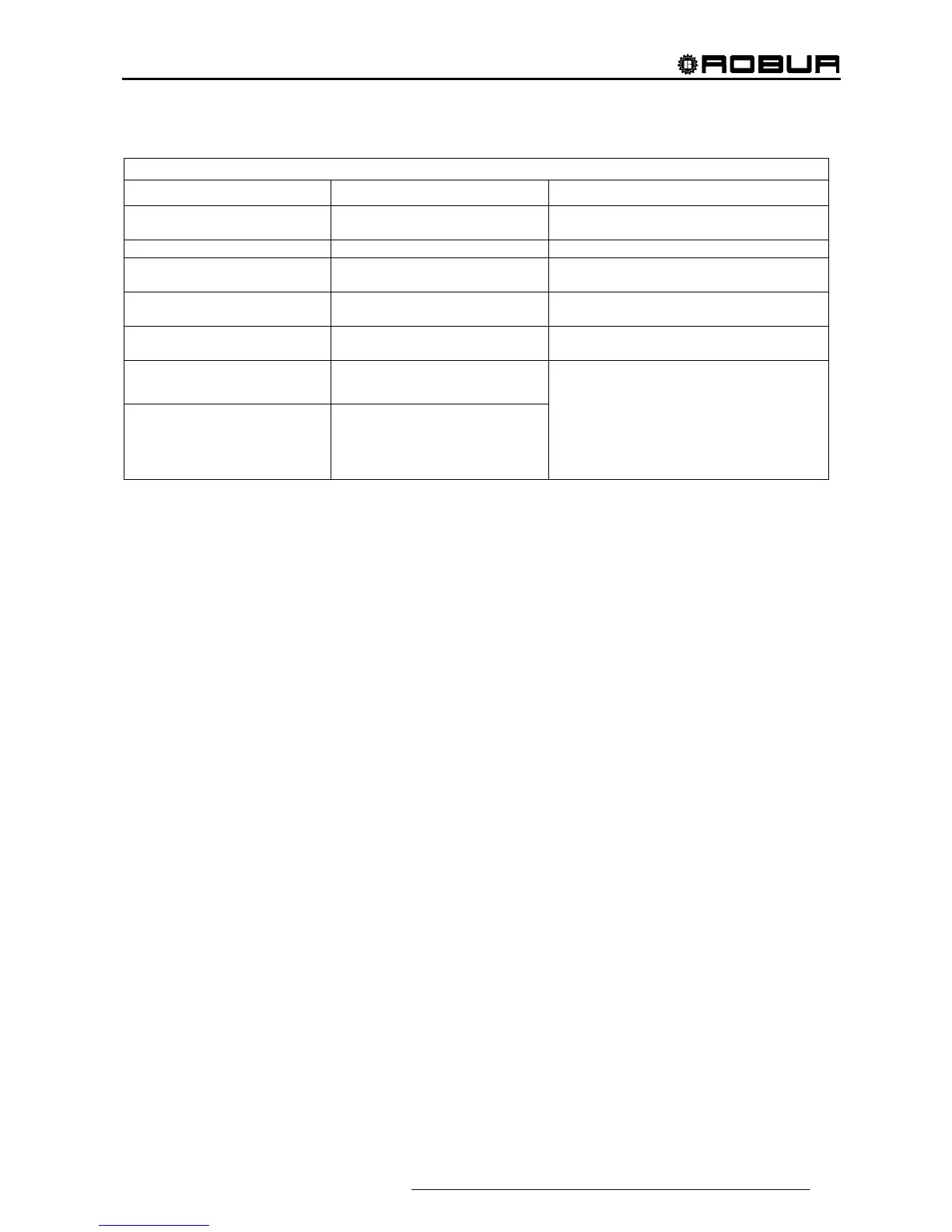

Default values of the parameters and indications for correct choice of their values (categories 4 - 7)

Default values

Parameter Value of Categ. 4 - 7 Recommended setting

Machine power 35 kW

Set the power value in kW of the single

machine belonging to the category

Priority 3 Set a value between 0 and 4

Prevention time 2 minutes

Set a value suited to the type of

machine used

Minimum activation time 3 minutes

Set a value suited to the type of

machine used

Number of stages 10

Use the maximum value possible for the

number of machines present

Enable integral

6 °C * minutes

(10,8 °F * minutes)

Disable integral

8 °C * minutes

(14,4 °F * minutes)

Use the semi automatic configuration

(refer to paragraph 4.4.2.5.4 Regulation

parameters 89), which calculates the

value of these parameters according to

the other data set for all categories; the

calculation is made when exiting the

configuration panel

Table 2 - REGULATION PARAMETER DEFAULT VALUES HEATING SERVICE (categories 4 - 7)

Guide lines for the calibration of the parameters on the basis of the observation of the behaviour of the

system.

The values for the automatically set integrals using the semi-automatic configuration refer to plants with

normal heat inertia.

If systems must be regulated with very low or very high inertia values, it is possible that the regulation

parameters are calibrated differently.

Several guide lines are given below:

• The first indicator of a well-regulated system is that in normal conditions (with constant load) there is

only one intermittent stage.

If, however, there are several intermittent stages in normal running conditions, the integrals must be

increased, both prevention and enabling.

• If the response to load or set point variations is too slow:

o reduce the integrals, both prevention and enabling;

o reduce the number of stages, only after having acted with the previous option.

• If a single stage is too intermittent:

o maximise the number of stages;

o increase the differential [default = 2°C (3,6° F)] without exaggerating so as not to shift too far

away from the set point.

• If too marked overshoots are observed (the temperature rises too much over the set point):

o reduce the prevention inhibition;

• If too marked overshoots are observed (the temperature falls too much below the set point):

o reduce the enabling inhibition;

When a set point is requested that is very near to the operational limits of the machines, if the load is low the

system will regulate badly as the machines will tend to go continuously into limit thermostating.

To prevent this phenomenon that largely worsens yield, it is necessary to intervene with the activation of the

climatic curves or, alternately, reduction of the set point (in heating mode).

In the case of systems with common pump, where the phenomenon is particularly marked, it is also possible

to intervene by reducing the number of stages.

Third party boiler water pump delay

Only for categories 4, 5, 6 and 7, for third party boilers, this parameter is also present. For a given category,

the parameter is present when assigned to boilers with dedicated water pumps controlled by the Robur

system; this has the purpose of establishing the switch off delay for this type of water pump. If more than one

Loading...

Loading...