LUBRICATION

ALWAYS STOP THE MANURE SPREADER AND DISCONNECT POWER BEFORE SERVICING,

REPAIRING, OR CLEANING. USE SAFE SHOP PROCEDURE AND EXERCISE CAUTION WHEN

WORKING ON THIS MACHINE!

It is extremely important to properly lubricate your new RODA machine before it is used for the first time. If

the mechanical drive components of your unit are not protected from shock and frictional abrasion, the wear

rate of these components will be vastly accelerated and their life span will be drastically reduced. For proper

care and maintenance, your machine should be serviced with engine oil, multipurpose grease, and fluids

specified below.

It is extremely important that the lubrication guide be followed. For lubricating bearings, use good quality

multipurpose grease. Pump the grease in slowly. Roller chains should be lubricated with engine oil, or a spray-

on chain lubricant and then the spreader operated under a no-load condition. This will allow the roller chains to

be thoroughly lubricated and thus minimize heat-up during operation.

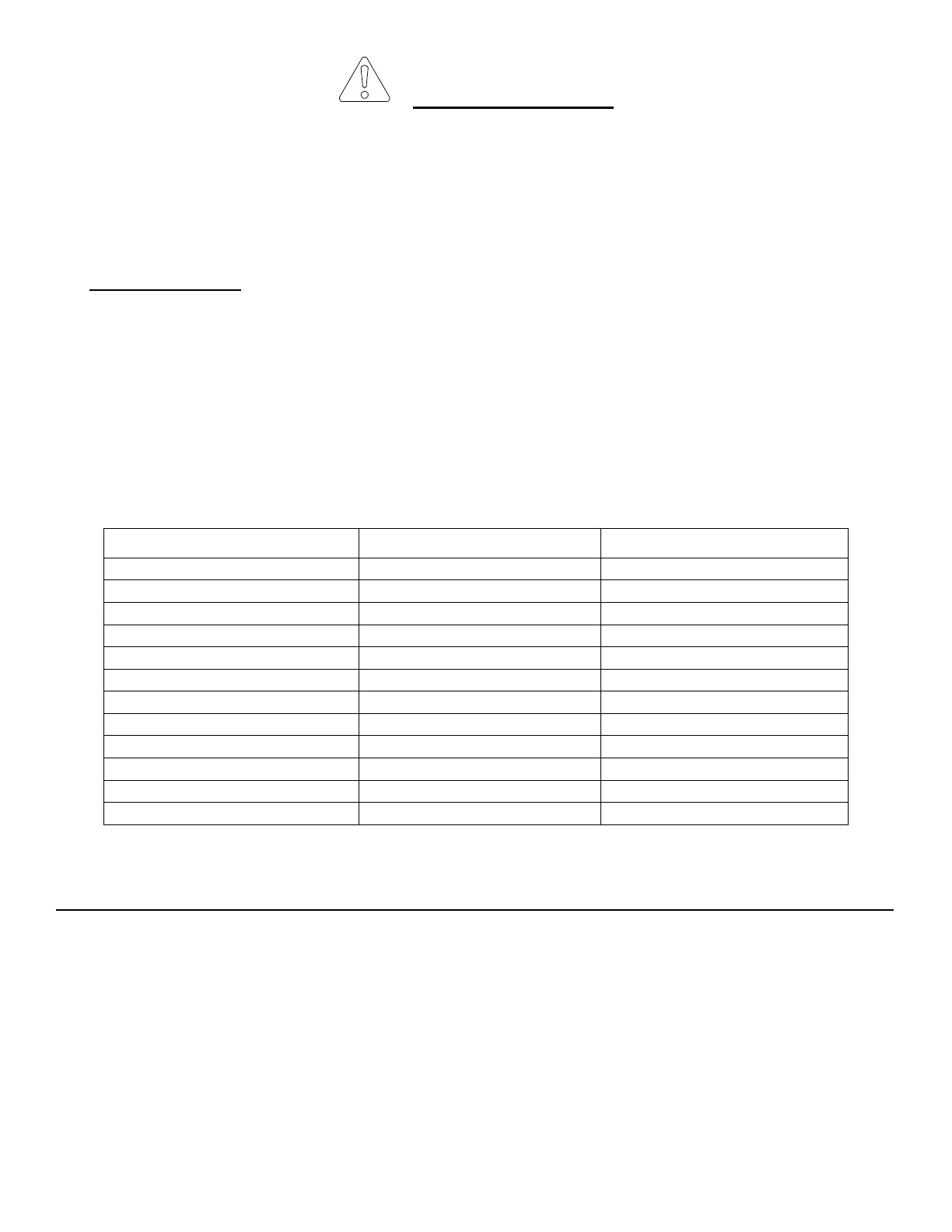

DESCRIPTION INTERVAL LUBRICANT

ROLLER CHAINS 15-20 HOURS OIL

APRON BEARINGS 15-20 HOURS GREASE

APRON GEAR CASE ANNUALLY EP90 GEAR LUBE

APRON CHAIN WHEN PARKED 30WT OIL

RIGHT ANGLE GEAR CASE ANNUALLY EP90 GEAR LUBE

GEARBOX KNUCKLE 15-20 GREASE

AXLE HUBS BI-ANNUALLY GREASE

PTO SHAFT 15-20 GREASE

SLIP CLUTCH BI-ANNUALLY GREASE

CAST FLANGE BEARINGS 15-20 HOURS GREASE

PILLOW BLOCK BEARING 15-20 HOURS GREASE

SLOP GATE PIVOT POINT 15-20 HOURS GREASE

ALWAYS REPLACE ALL SHIELDS AFTER MAINTENANCE AND LUBRICATION IS COMPLETE

12

Loading...

Loading...