If one only operates with one collar, the free side of the T-distributor has to be

closed by the closing nut. If a 3. or further freezing points are required, additional

T-distributors (accessory) can be connected to the T-distributor.

WARNUNG

displaces air! Do not use ROLLER’S Polar in submerged rooms (pits,

2

displaces air! Do not use ROLLER’S Polar in submerged rooms (pits,

2

The water (or other liquid) in the pipe can only be frozen when it is no longer

fl owing. All pumps must therefore be stopped and no liquid removed or allowed

to escape from the pipe. Before freezing, let the water cool down to room

Fully open the cylinder valve. The amount of CO

required is controlled auto-

2

required is controlled auto-

2

expands in the injector and forms dry ice with a

temperature of –79°C and freezes the water within the pipe. After a brief period,

frost will form on the pipe in the vicinity of the freeze collars. If frost does not

form in accordance with time given in the table, then this indicates that the

liquid within the pipe is still fl owing (check that all pumps have been switched

off and prevent any removal or outfl ow of water) or the water is too warm. While

work is in progress, the fl ow of CO

refrigerant must be maintained, and the

2

refrigerant must be maintained, and the

2

must fl ow out constantly between pipe and collar (pressure compensation).

2

must fl ow out constantly between pipe and collar (pressure compensation).

2

Always ensure a suffi cient supply of refrigerant by providing a stand-by cylinder.

The only way to determine the amount of remaining CO

is to weigh the cylinder.

2

is to weigh the cylinder.

2

If it is necessary to change the cylinder during work, it is essential that this proce-

dure should be complete within 7 minutes to prevent the ice pack from melting.

Once work is complete, close the cylinder valve and wait until the pressure in

the high-pressure hoses has returned to normal. Remove the high-pressure

hoses. Once the ice pack has

remove the handle pieces with injector from the freeze collar and remove the

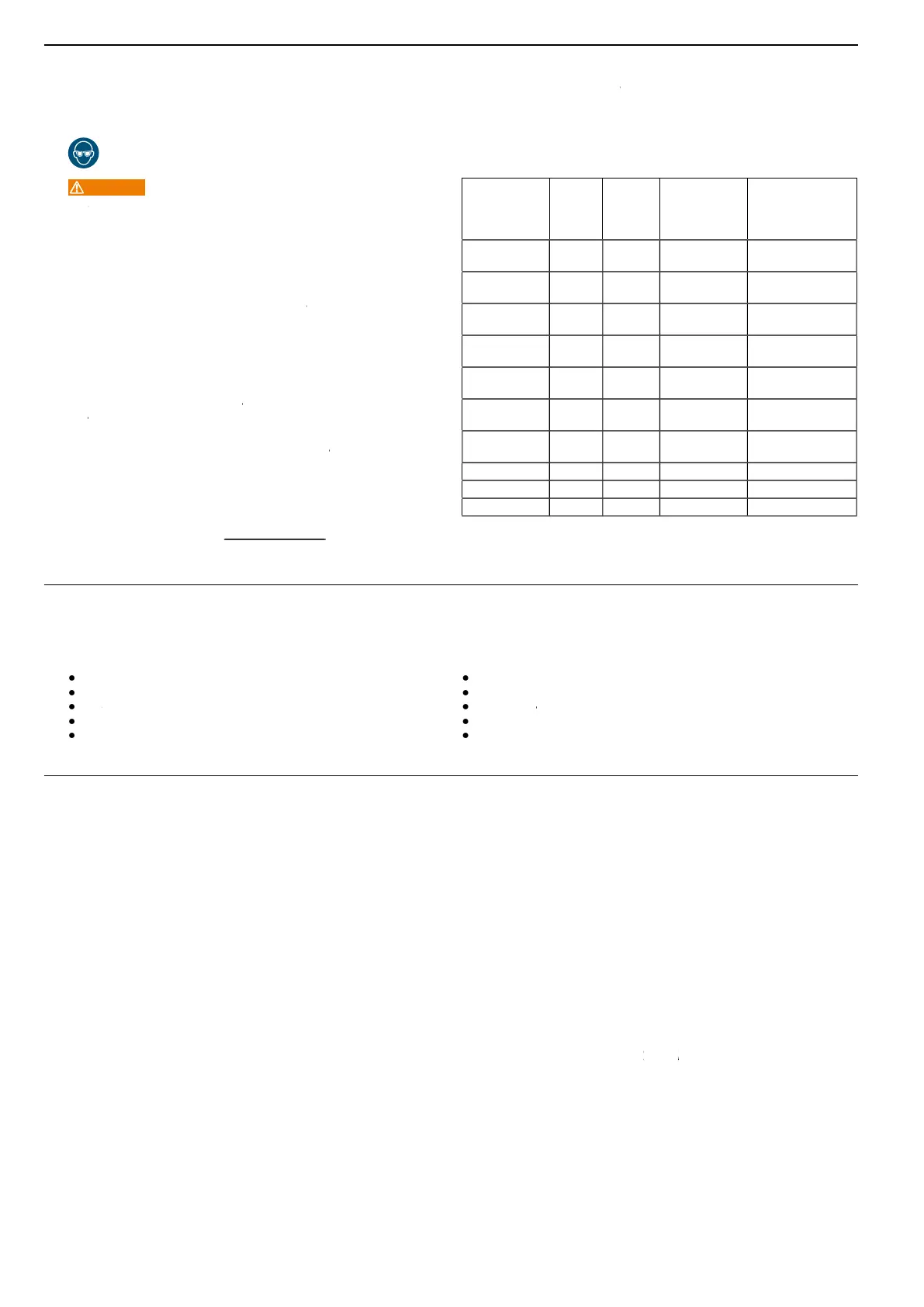

The freezing times and CO

requirements given in the table below are only to

2

requirements given in the table below are only to

2

be regarded as general guidelines and are valid for a water temperature of

approx. 20°C. The freezing times and refrigerant consumption values will there-

fore vary for higher temperatures. For freezing liquids in plastic pipes much

longer freezing times are generally required.

* Does not include work time

may not be thrown into the domestic waste at the end of use

but must be disposed of properly by law.

7. Manufacturer’s Warranty

The warranty period shall be 12 months from delivery of the new product to the

fi rst user. The date of delivery shall be documented by the submission of the

original purchase documents, which must include the date of purchase and the

designation of the product. All functional defects occurring within the warranty

period, which are clearly the consequence of defects in production or materials,

will be remedied free of charge. The remedy of defects shall not extend or

renew the warranty period for the product. Damage attributable to natural wear

and tear, incorrect treatment or misuse, failure to observe the operational

instructions, unsuitable operating materials, excessive demand, use for unau-

thorized purposes, interventions by the customer or a third party or other

reasons, for which ROLLER is not responsible, shall be excluded from the

Services under the warranty may only be provided by customer service stations

authorized for this purpose by ROLLER.

Complaints will only be accepted if

the product is returned to a customer service station authorized by ROLLER

without prior interference and in a fully assembled condition. Replaced products

and parts shall become the property of ROLLER.

The user shall be responsible for the cost of shipping and returning the product.

A list of the ROLLER-authorized customer service stations is available on the

Internet under www.albert-roller.de. For countries which are not listed, the

product must be sent to the SERVICE-CENTER, Neue Rommelshauser Strasse

4, 71332 Waiblingen, Deutschland. The legal rights of the user, in particular

the right to make claims against the seller in case of defects as well as claims

due to wilful violation of obligations and claims under the product liability law

are not restricted by this warranty.

This warranty is subject to German law with the exclusion of the confl ict of laws

rules of German International Private Law as well as with the exclusion of the

United Nations Convention on Contracts for the International Sales of Goods

(CISG). Warrantor of this world-wide valid manufacturer’s warranty is Albert

Roller GmbH & Co KG, Neue Rommelshauser Straße 4, 71332 Waiblingen,

For spare parts lists, see

→ Downloads → Parts lists.

Procedure in Case of Trouble

Frost does not form on the pipe.

Freezing time still too short.

Pay attention to freezing times according table.

Pumps not switched off, outfl ow of water.

Switch off pumps. Stop water removal.

cylinder is empty or cylinder valve is not open.

2

cylinder is empty or cylinder valve is not open.

2

cylinder or open cylinder valve.

2

cylinder or open cylinder valve.

2

Choke in cylinder connector with T-distributo

Filter in front of injector nozzle blocked up.

Filter in front of injector nozzle blocked up. Unscrew injector nozzle, push fi lter

carefully from the back through the handle piece

, clean fi lter (blow out).

Loading...

Loading...