17

RootsScrub B45 Series

Ÿ For reasons of safety during cleaning and/or maintenance

work in or on the tank, the tank lid - when lifted - must be

secured so as to prevent accidental closing or tilting down.

Ÿ The machine may be taken into operation only if all guarding

devices are fitted and in protective position. As far as

possible, cleaning should not be done by hand, but using

appropriate tools or equipment.

Ÿ Maintenance and repair work may be carried out only by

means of suitable tools and by the people trained in the

factory - for reasons of safety, only genuine Roots spare parts

may be used.

The electrical equipment of this machine uses a mains

voltage of 24 DC. Easy access to brush motor and vacuum

motor is possible after the upper part of the unit has been

titled to upside.

The suction turbine has been provided with a fuse having a

rating of 25A. It must be replaced by a fuse of same rating.

The brush motor is protected by a fuse having a rating of 35A.

When brush motor trips identify the cause and correct it

before trying to run the machine.

The fuses can be changed by removing the rear panel

assembly.

MAINTENANCE

- If there should be repeated cases of failure, look for

the reason.

- Any work at the electrical system has to be carried

out by specialized electricians only.

Maintenance Work

Compliance with our recommendations concerning

maintenance work will give you the certitude always having a

machine at your disposal, which is ready to work and in good

operating condition.

Please contact your local Roots Multiclean distributor; the

people there will be glad to perform that work for you. There

well trained personnel and genuine Roots spare parts are at

your disposal.

Ÿ Well trained personnel and genuine Roots spare parts

are at your disposal.

Ÿ In case of any inquiries or orders for spare parts, please

always quote the machine's serial number mentioned on

the nameplate.

Ÿ The name plate is fixed in the rear side of the machine.

Ÿ When cleaning or servicing the machine, and when

replacing any parts, shut off the machine and on principle

disconnect the power plug from the power supply.

Electrical System

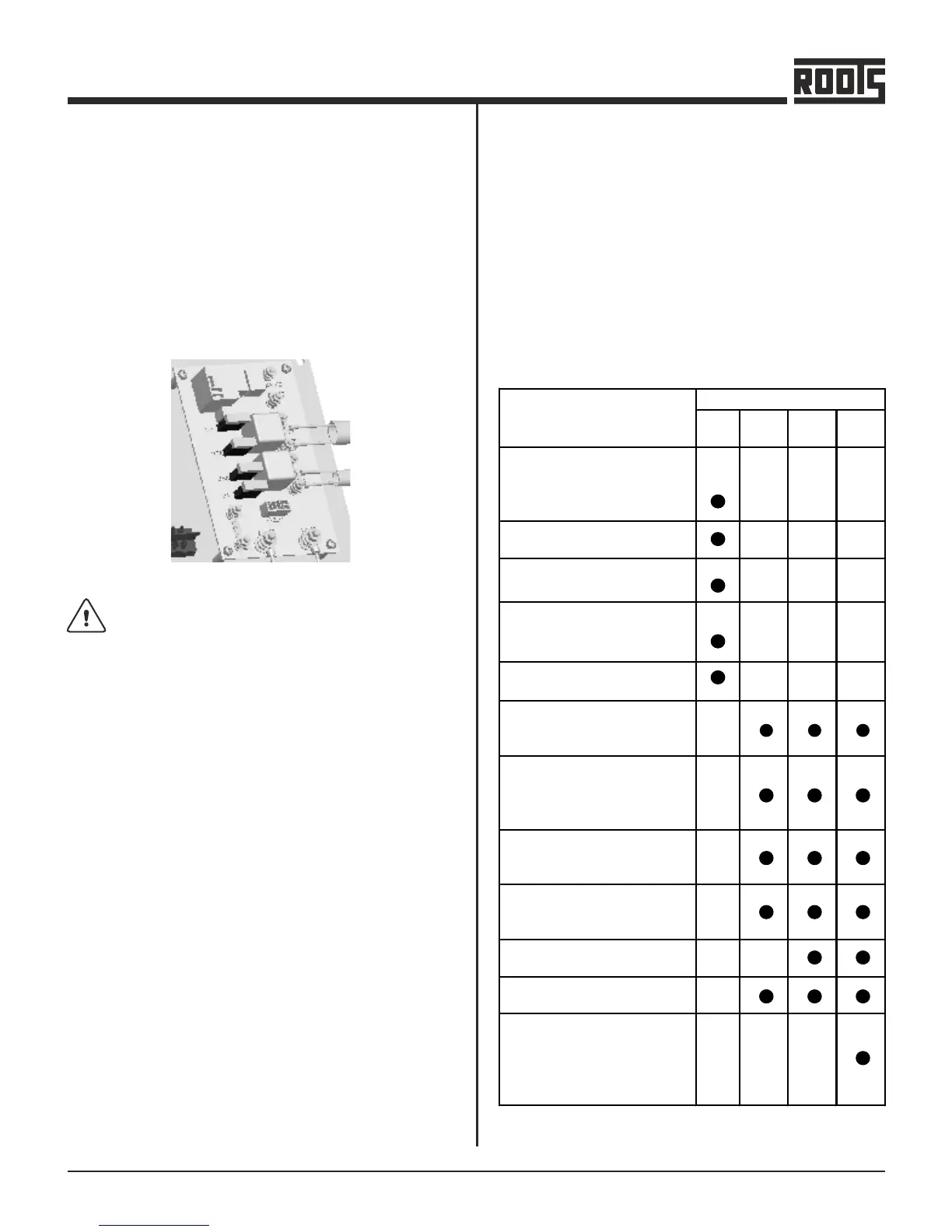

Maintenance Schedule

Daily

Every

50

Every

100

Every

200

Service Hours

Maintenance Schedule

Check connection - extension

cables and plugs for good

condition; discard Defective

cables immediately

Empty and clean the dirty water

tank

Check the sealing strips of

squeegee for good condition

Check the float for proper

operation

Check the squeegee for possibly

collected foreign matter and

clean it, if required

C h e c k t h e s u c t i o n h o s e

between squeegee and Dirty

water tank

Check the caps of both Fresh

and dirty water drain hose;

c h e c k t h e m f o r s m o o t h

operation

Remove carbon dust from the

suction motor, check the carbon

brush for smooth operation and

wear; renew as required

Check the squeegee sealing

strips for wear; renew them if

required

Check the brush for tight fit and

wear; renew them if required

Check the tank lid seal; renew if

it is required

Check the fresh water infeed to

the brush

Loading...

Loading...