MODEL F73(17603)

37

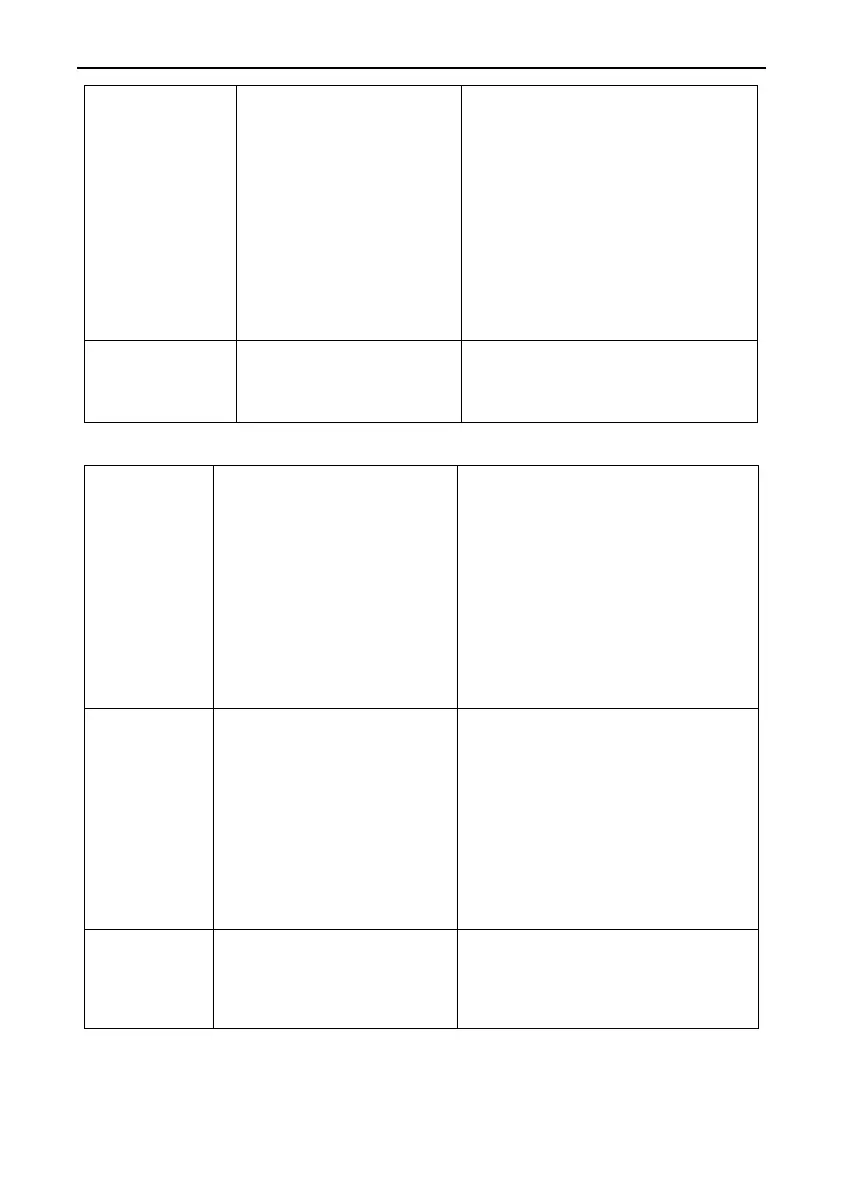

4. Softener fails

to draw brine.

A. Line pressure is too

low.

B. Brine line is plugged.

C. Brine line is leaking.

D. Injector is plugged.

E. Internal control leak.

F. Drain line is plugged.

G. Sizes of injector and

DLFC not match with

tank.

A. Increase line pressure.

B. Clean brine line.

C. Replace brine line.

D. Clean or replace injector.

E. Check valve body and change

if necessary.

F. Clean drain line flow control.

G. Select correct injector size and

DLFC according to the P20

requirements.

5. Unit used too

much salt.

A. Improper salt setting.

B. Excessive water in

brine tank.

A. Check salt usage and salt

setting.

B. See problem no.6.

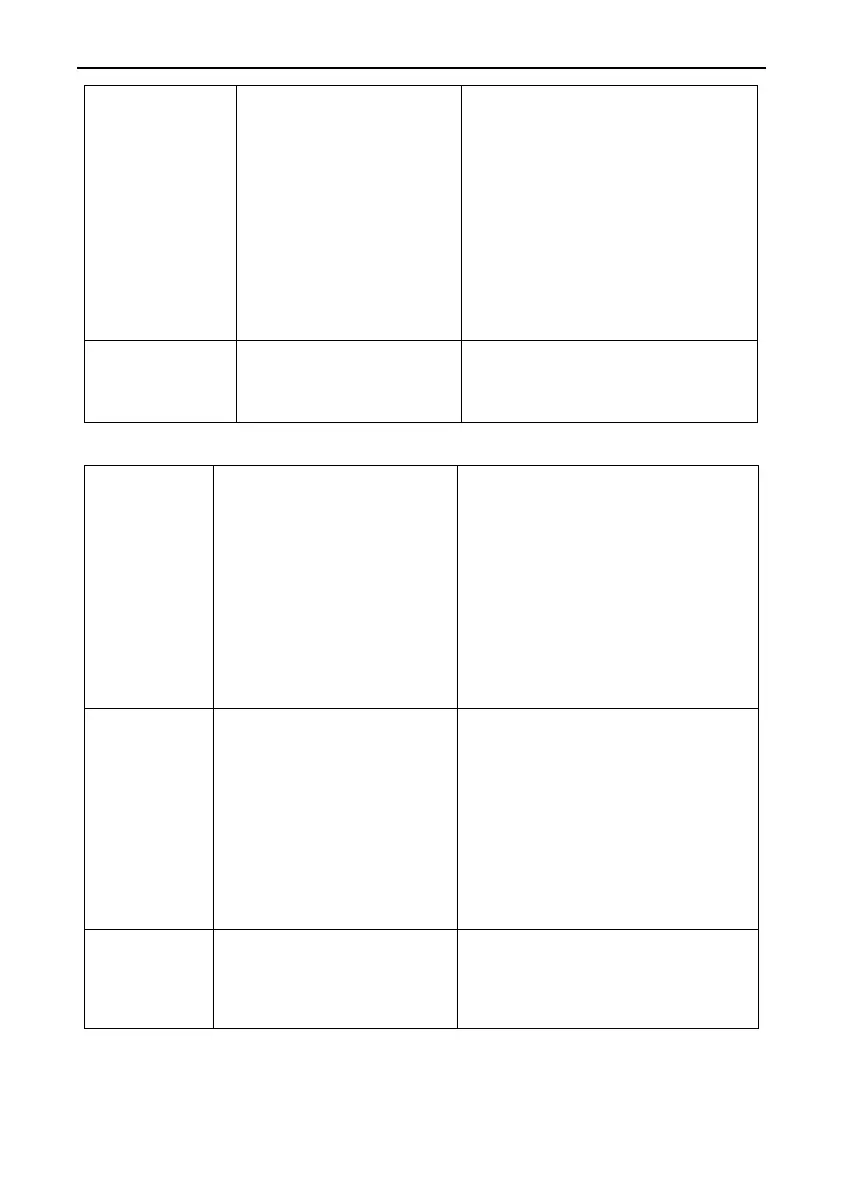

6. Excessive

water in brine

tank.

A. Overlong refilling time.

B. Remain too much water

after brine.

C. Foreign material in brine

valve and plug drain line

flow control.

D. Not install safety brine

valve but power failure

whiling salting.

E. Safety brine valve

breakdown.

A. Reset correct refilling time.

B. Check the injector and make

sure no stuff in the brine pipe.

C. Clean brine valve and brine line.

D. Stop water supplying and restart

or install safety brine valve in salt

tank.

E. Repair or replace safety brine

valve.

7. Pressure

lost or rust in

pipe line.

A. Iron in the water supply

pipe.

B. Iron mass in the softener.

C. Fouled resin bed.

D. Too much iron in the raw

water.

A. Clean the water supply pipe.

B. Clean valve and add resin

cleaning chemical, increase

frequency of regeneration.

C. Check backwash, brine draw

and brine tank refill. Increase

frequency of regeneration and

backwash time.

D. Iron removal equipment is

required to install before softening.

8. Loss of

resin through

drain line.

A. Air in water system.

B. Bottom strainer broken.

C. Improperly sized drain

line control.

A. Assure that well system has

proper air eliminator control.

B. Replace new strainer.

C. Check for proper drain rate.

Loading...

Loading...