30

Start-Up

5.0 SYSTEM START-UP AND REFRIGERANT CHARGING

5.7 Indoor Air-Flow Verication

Correct indoor air-flow and proper supply air

distribution is critical to system comfort, efficiency

and reliability. Excessive indoor air-flow results in

elevated humidity levels in the cooling mode and

excessive air noise. Low indoor air-flow reduces

system capacity and can result in coil icing and

compressor failure in the cooling mode and can

cause nuisance high pressure switch tripping and

increases power consumption in the heating mode.

Fortunately, when the RD17AZ outdoor unit is matched

to the correct air-handler or furnace/coil combination

and are controlled by the communication EcoNet

TM

Control Center, the indoor air-flow is automatically

controlled to the proper level based on the model

data stored in the UODC. When the indoor blower is

operating, the EcoNet

TM

Control Center will display

the indoor air-flow in the Service Menu of the control.

The approximate indoor air-flow is also displayed in

100 CFM [47 l/s] increments by a flashing LED on the

air-handler or furnace control board while the blower

is operating (one flash per 100 CFM [47 l/s]) for

installations where a conventional 24VAC thermostat

is used.

Once the system is operating in the Charging Mode,

confirm the indoor air-flow is close to those values in

the table below. If the displayed indoor air-flow is not

reasonably close to the value in the table, confirm

cooling dehumidification is disabled, the indoor air-

flow trim adjustment is set to 0%, and verify the

model numbers of the indoor and outdoor units are

an approved combination by the manufacturer. Once

the indoor air-flow is verified, the indoor air-flow trim

adjustment may be changed to suit the installation

and should be done prior to final charge adjustment.

NOTICE: AHRI rated indoor air-flow may differ

slightly from values in the table below.

NOTE: All indoor air-ow trims must be adjusted

using the bluetooth contractor's app.

The refrigerant charge for all systems should be

checked against the Charging Chart located inside the

access panel cover.

WARNING:

The top of the compressor

shell is hot. Touching the compressor top may result in

serious personal injury.

CAUTION:

R-410A pressures are

approximately 60% higher (1.6 times) than R-22

pressures. Use appropriate care when using this

refrigerant. Failure to exercise care may result in

equipment damage or personal injury.

Charge for all systems should be checked against the

Charging Chart inside the access panel cover.

IMPORTANT: Do not operate the

compressor without charge in the system.

Addition of R-410A will raise high-side pressures

(liquid and discharge).

NOTICE: System maintenance is to be

performed by a qualified and certified technician.

The optimum refrigerant charge for any outdoor unit

matched with an indoor coil/air handler is affected

by the application. Therefore, charging data has

been developed to assist the field technician in

optimizing the charge for all mounting configurations

(UF – Upflow, DF – Downflow, LH – Left-Hand

Discharge, and RH – Right-Hand Discharge). Refer to

the charging chart inside the access panel cover on

the unit and choose the appropriate column for the

specific application being installed or serviced. New

installations utilizing either an RCF indoor coil installed

on a gas furnace, RH3VZ or an RHMVZ series air

handler in the downflow or horizontal right-hand

discharge may require removal of some refrigerant

since the factory charge could result in an overcharge

condition for short line length applications.

The following method is used for charging systems in

the cooling and heating mode. All steps listed should

be performed to ensure proper charge has been set.

For measuring pressures, the service valve port on

the liquid valve (small valve) and the true service port

located between the two service valves are to be

used.

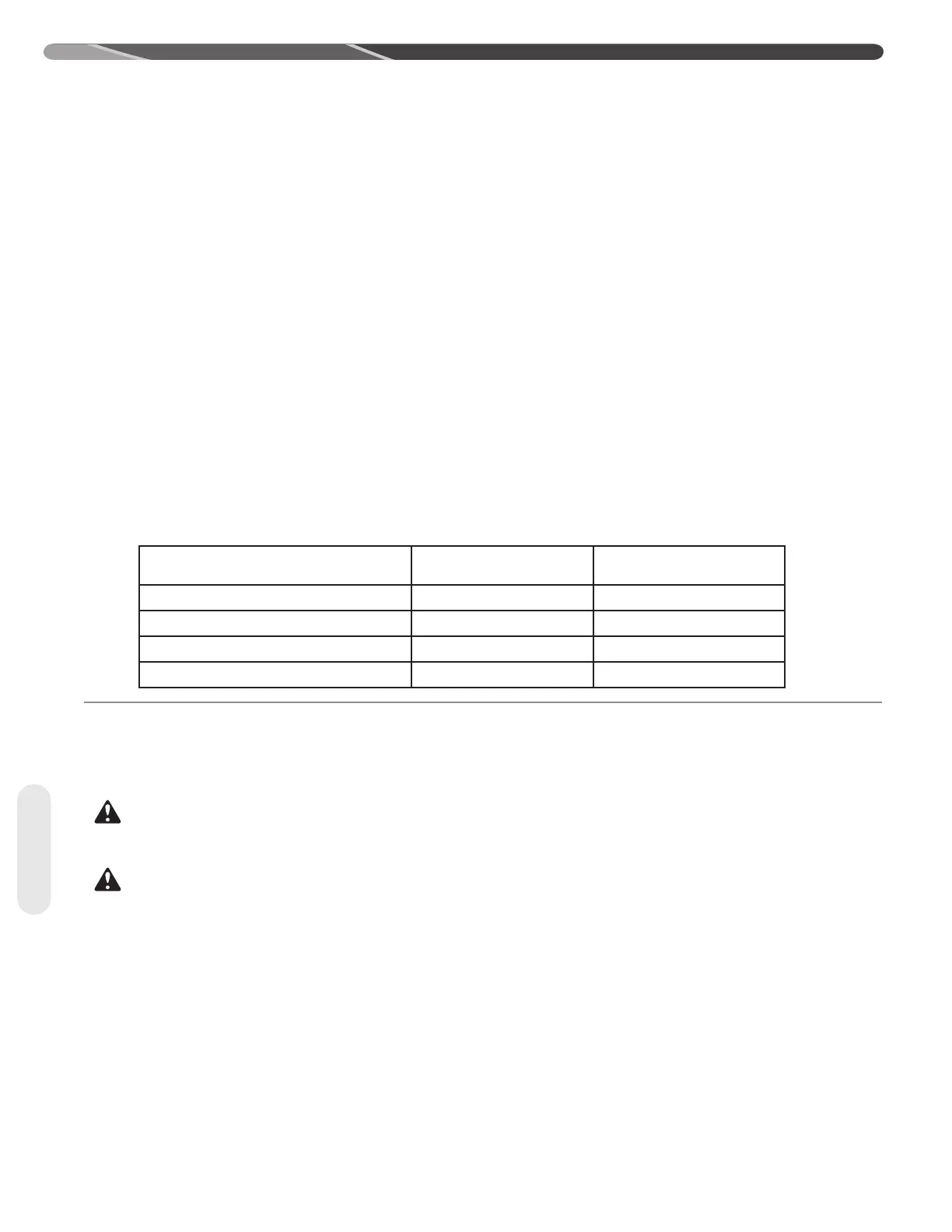

5.8 Refrigerant Charging

Outdoor Unit

Model No.

Displayed Indoor CFM

Cooling Mode

Displayed Indoor CFM

Heating Mode

RD17AZ24AJ3CA 750 750

RD17AZ36AJ3CA 1125 1125

RD17AZ48AJ3CA 1450 1450

RD17AZ60AJ3CA 1800 1800

Loading...

Loading...