36

7.0 COMPONENTS & CONTROLS

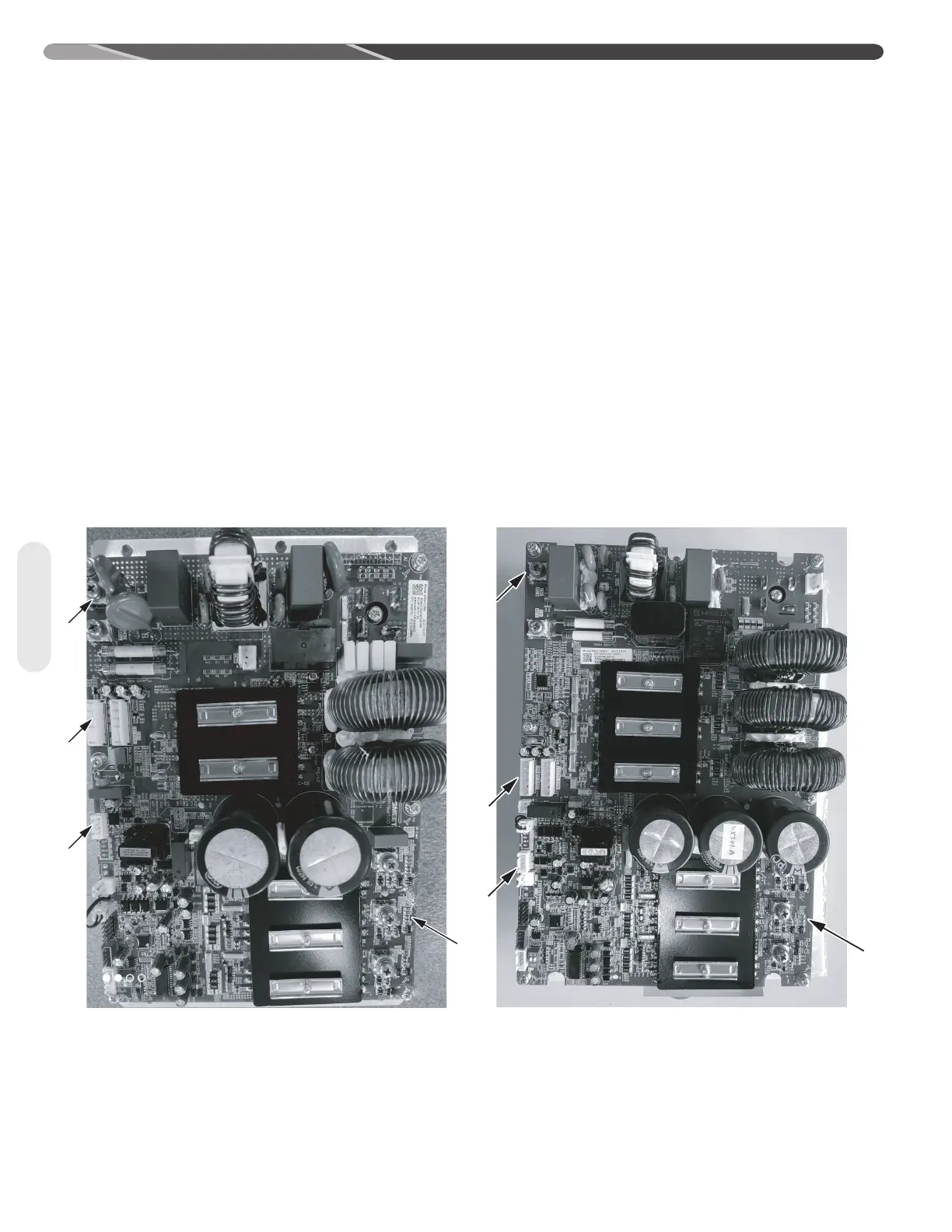

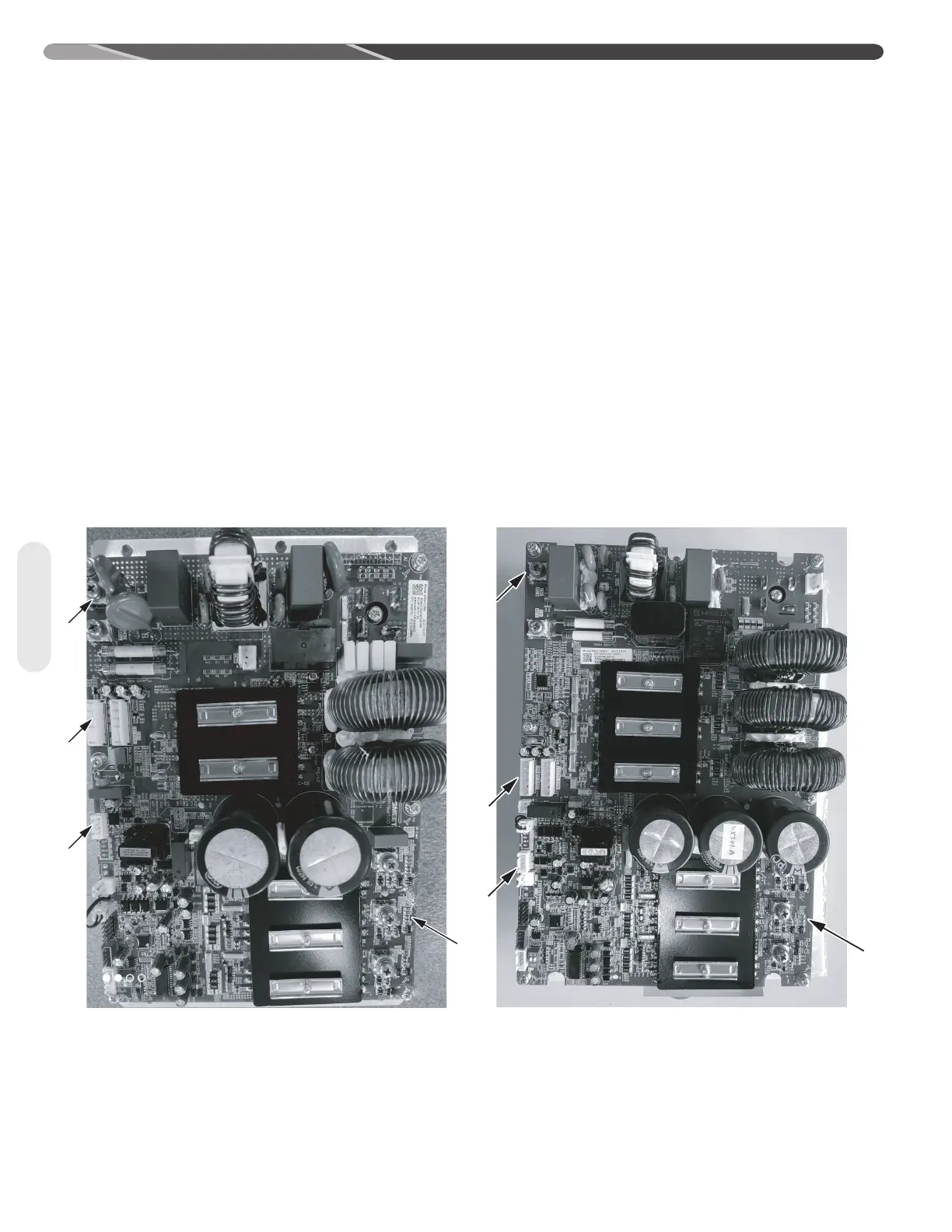

7.2 Power Inverter Compressor

Control

RD17AZ outdoor units are equipped with a power

inverter that varies the compressor speed to match

the changing capacity needs of the conditioned

space. The inverter interfaces with the Universal Out-

door Control (UODC) which communicates the level

of system capacity that is required to the inverter

based on input from the EcoNet

TM

Control Center

or conventional 24VAC 2-stage thermostat. The

inverter converts incoming single phase power to

simulated variable frequency 3-phase power that is

connected to the 3-phase compressor motor. Each of

the four (-)P20 models has a unique inverter specifi-

cally designed and qualified for that specific model to

provide reliable operation under the most extreme

conditions. Each inverter is programmed to monitor,

input current, input voltage, Compressor speed and

Fan speed. When the inverter identifies a condition

that could potentially result in compressor or inverter

damage, it automatically reduces the compressor

speed until a more reliable operating condition is

obtained or shuts the compressor completely off

if necessary. Once safe operating conditions are

attained, the inverter will gradually increase the com-

pressor speed in an attempt to meet the capacity

demand as long as the operating conditions remain

within the safe operating range of the compressor

and inverter.

1. RS485 Communication

2. Input Power

3. Drive Output

4. OD Fan Motor

Components

2/3 Tons 4/5 Tons

Loading...

Loading...