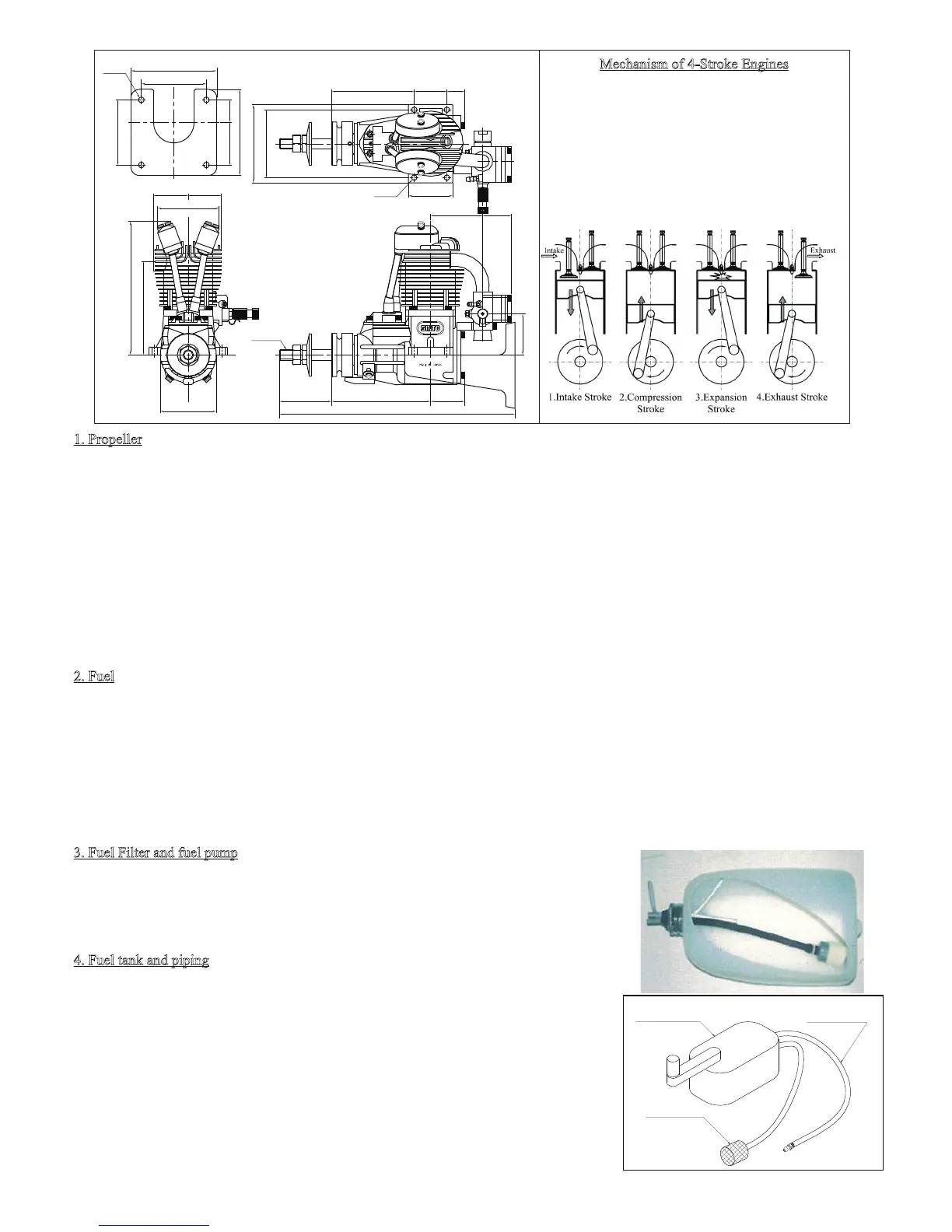

Mechanism of 4-Stroke Engines

The 4-Stroke engine provides 4 individual piston

movements as illustrated below. The “Stroke”

means the piston movement from the Top Dead

Center to the Bottom Dead Center. In the 4-Stroke

engine, one cycle of operation in change of gas

state inside the cylinder and valve movement are

completed at every 4 strokes of piston that is every

2 revolutions of the crankshaft. Formally the

engine is called the 4-stroke one-cycle engine.

1. Propeller

Depending on the airframe, please adopt the standard size in the data and use a reliable product which is generally on the market. (Carbon

made prop is recommended)

Since a large-diameter prop is used, please maintain sufficient balance. Since an imbalanced prop is vibratory and dangerous with lowered

performance, please maintain balance with a balancer. Moreover, a cracked prop is dangerous. Please be sure to check any time and

replace it with a new one if it’s cracked.

*Prop and fuel consumption

If the load is large (the diameter & pitch of the prop is large) for the engine characteristics, the air-fuel mixture should be rich. Thus the

main needle has to be opened. That is, even if the revolution is low, the fuel consumption is high. Conversely, when the load is small and

the revolution is high, the fuel consumption is lowered because the main needle can be closed.

In order to decrease the fuel consumption and prolong the engine life, a propeller should be used whose revolution is maximized when the

throttle-valve is fully opened, while using an airframe which enables all flights with about 90% of the output of the propeller. In this case,

the throttle valve will be further throttled during horizontal flight. On the contrary, an airframe which can only deliver performance in

fully open condition will suffer worsening fuel consumption and life.

2. Fuel

The fuel is mixture of commercial regular gasoline and reliable oil for 2-stroke. (In addition, unleaded high-octane gasoline is not neces-

sarily required for our engine.) [Example of oil]

・ POWER LUBE (KLOTZ ORIGINAL TECHNIPLATE)

・ KLOTZ GS RC model LUBE

・ CASTROL POWER1 TTS Racing, etc.

For the mixture ratio, please be sure to use “gasoline : oil = 20 : 1” or richer by volume ratio. Any damage caused by the fuel used, in

which the oil ratio is lower than 20:1 ratio, is not warranted.

Since gasoline is a dangerous material, be careful of its storage, use, and transport enough. (The evaporative emission and exhaust smoke

of gasoline have a harmful effect on a human body. Also, if gasoline is leaked, there is danger of fire etc.) Please note that we takes no

responsibility for accidents, health damages, etc which occur during storage, use and transport of gasoline.

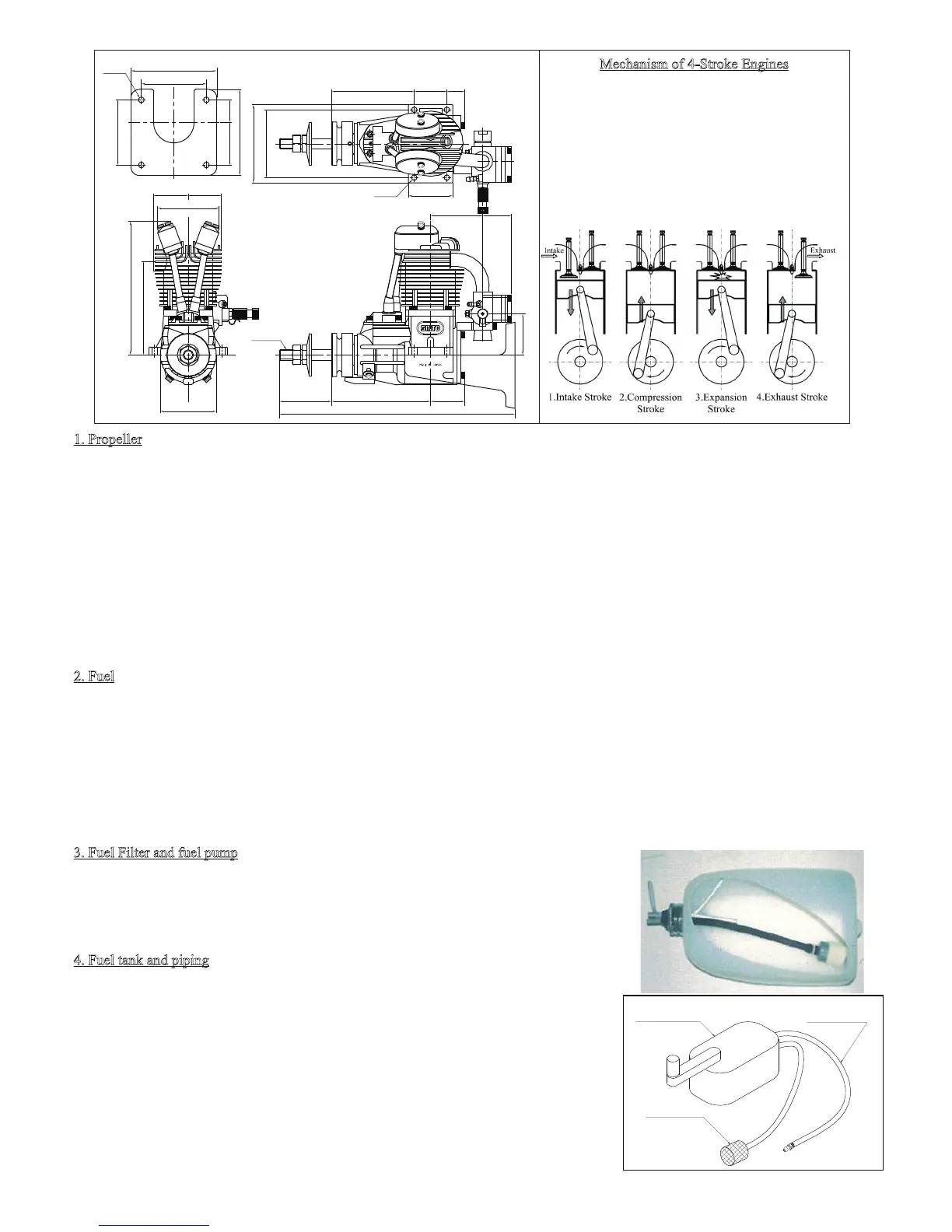

3. Fuel Filter and fuel pump

Since commercial gasoline has many impurities, please be sure to use a reliable filter for

the admission port of the gasoline fuel pump (Fig.2) or the filter with weight in the fuel

tank as the following picture shows.

Without using a filter, the performance of the carburetor is not delivered, resulting in

failures.

4. Fuel tank and piping

For the capacity (about 200cc-250cc), refer to the data and select the best of commercial

product. Please be sure to use a filter with weight. To avoid entrain any impurities to the

carb, piping with “Fuel feeding pipe” and “Air inhalation pipe” (Fig.3) is recommended.

*Please be sure to use “gasoline-proof” products for the tank lid rubber, piping, and

tubing. Some of the products for glow fuel can’t be used for gasoline. Please check

carefully if there’re any clack of the piping, tubing, connection, and tank. All of the

connection part should be bound by thin Nylon strap or wire to avoid fuel leakage or air

induction to the fuel line. (If there are any leakages, the performance of the engine

decreases dramatically.)

*The tank should be placed within the range of 200mm from the engine center to the tank

center. When performing an acrobat with a large change in fuel level or that requiring an

excessive movement of throttle, the tank must be placed at a position close to the engine

as much as possible.

*When provide “Air inhalation pipe” as Fig.3, arranging the tube above the fuel level

(Fig.4) is the effective way of fuel leakage prevention.

Loading...

Loading...