21

ENGLISH

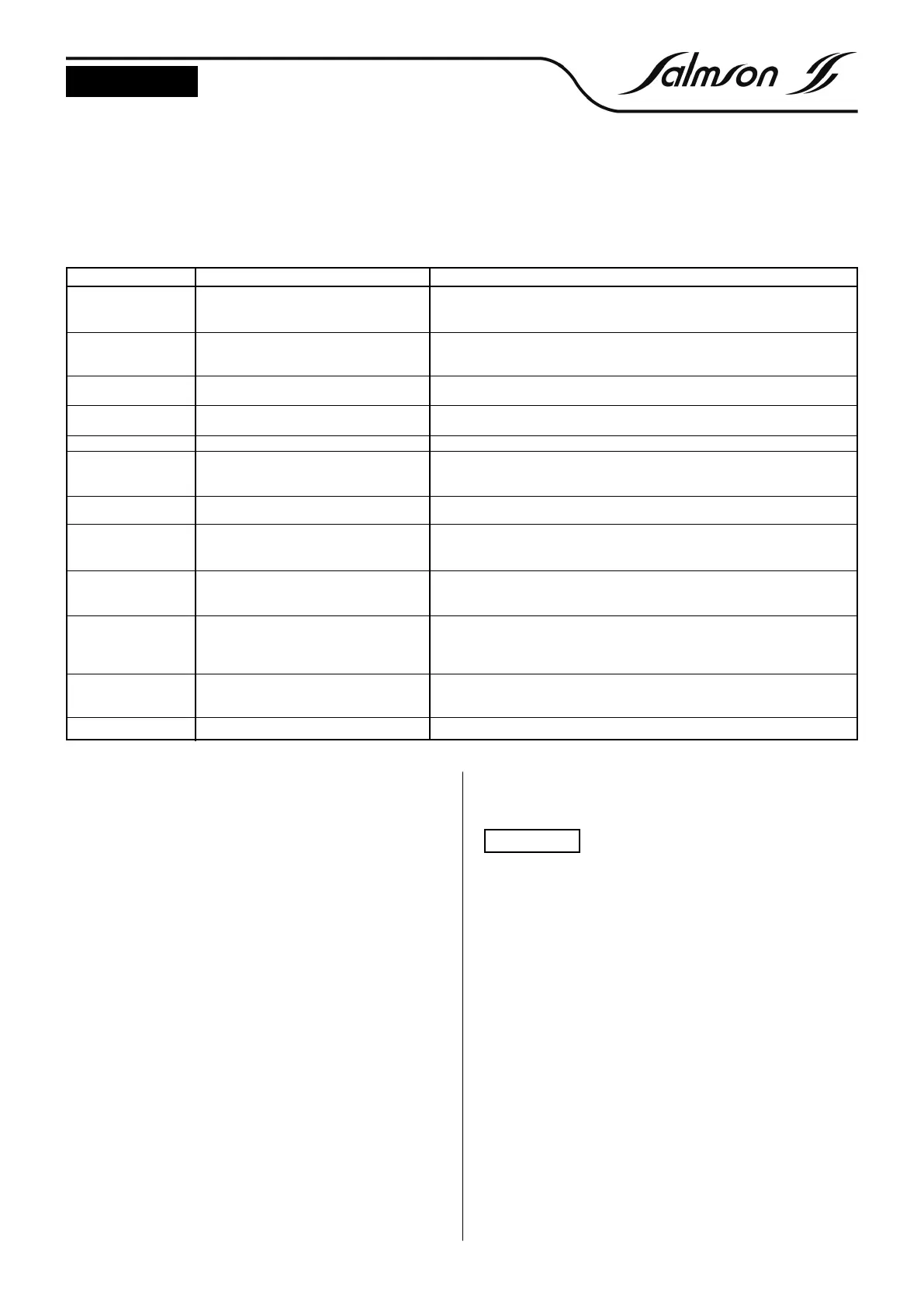

8. PROBLEMS, CAUSES AND REMEDIES

In case of system faults perform the following checks :

- Check for presence of foreign matter in the reservoir (in the bell).

- Check electrical connection (faulty fuse).

9. RETROFITS AND ACCESSORIES

9.1 Accessor

ies

Accessor

ies m

ust be or

dered separately.

- Electronic level sensor 0-1 mWS (4-20mA) with 10, 30 or 50m

connection cable.

- Safety barrier (zener barrier) in housing with connection cable

- Float switch.

-

Isolating switch amplif

ier for float switch for use in potentially explo-

sive areas.

-

Switch cabinet for outdoor installation (other accessories, e.g. swit-

ch cabinet heater, FI protection switch etc. available.

9.2 Assembly

- Mount switchgear.

- Perform settings.

- Functional check and start-up.

9.3 Electronic level IPAE sensor with zener barrier

For use in potentially explosive areas, a safety barrier (zener barrier)

m

ust be inserted between the sensor and the switch box.

9.3.1 Assembly

Electrical connection to terminals 25 and 26 :

The connection is m

ade as f

ollo

ws :

- Isolate control box from the power supply.

- Remove terminal cover from control box.

- Open housing with zener barrier.

-

Connect electronic sensor to zener barrier.

- Connect the connecting cables of the zener barrier to terminals 25

and 26 in the control box.

- Connect zener barrier to the potential equalisation (PA) (min. 4.0

mm

2

cooper).

Strictly follow the safety precautions for the zener

barr

ier

.

-

Close housing co

vers.

- Functional check and start-up.

Subject to technical alterations !

Indication in display

P1: Therm. fault 1

P2: Therm. fault 1

P1: Therm. fault 2

P2: Therm. fault 2

P1 : or P2 :

Overcurrent

P1 : or P2 : no load

Max. water level alarm

Max. water level float

Runtime alarm

Switch-on point

below switch-off point

Max. water level

below switch-on point

Switch-on point

above peak load

Faulty operation of

float switch

Interface < 3 mA

Fault description

Winding protection contact (WSK) of pump 1

or 2 has tripped (contact between terminals

31/32 or 38/39 has opened)

Winding protection contact (WSK) of pump 1

or 2 has tripped (contact between terminals

32/33 or 39/40 has opened)

The set motor limiting value has been excee-

ded

Phase L2 is not present or the control is opera-

ted without load

Level has exceeded the max. water level setting

Contacts of the float switch for max. water

level are closed, both pumps are activated or

are already active.

Triggered after third runtime changeover

The settings for switch-on and switch-off point

overlap

The setting for the max. water level alarm lies

below the switch-on point

The switch-on point of the base load pump

lies above the switch-on point of the peak

load pump

Plausibility check, float switches not connec-

ted in correct order

Current signal less than 3 mA

Remedy

Check pump; if clogged, remove foreign matter, if present. Check motor for sufficient

cooling (dry run)

Check pump; if clogged, remove foreign matter, if present. Check motor for sufficient

cooling (dry run)

Check motor current and set rated current; correct, if necessary

Check power supply; check pump and pump cable

Check pump for function or level setting

Check pumps for function or check float switch

Check pumps for function

Check level settings

Check level settings

Check level settings

Check float switches, check electrical connections

Check level sensor, check electrical connections

If the malfunction cannot be removed, please consult your sanitary and heating specialist or SALMSON Customer Service

If faults have occurred, they are shown alternately in the bottom line

on the display.

ATTENTION !

Loading...

Loading...