S&C ELECTRIC COMPANY

s

INSTRUCTION SHEET

716-501

Page 13 of 26

August 12, 2002

INSTALLATION — Continued

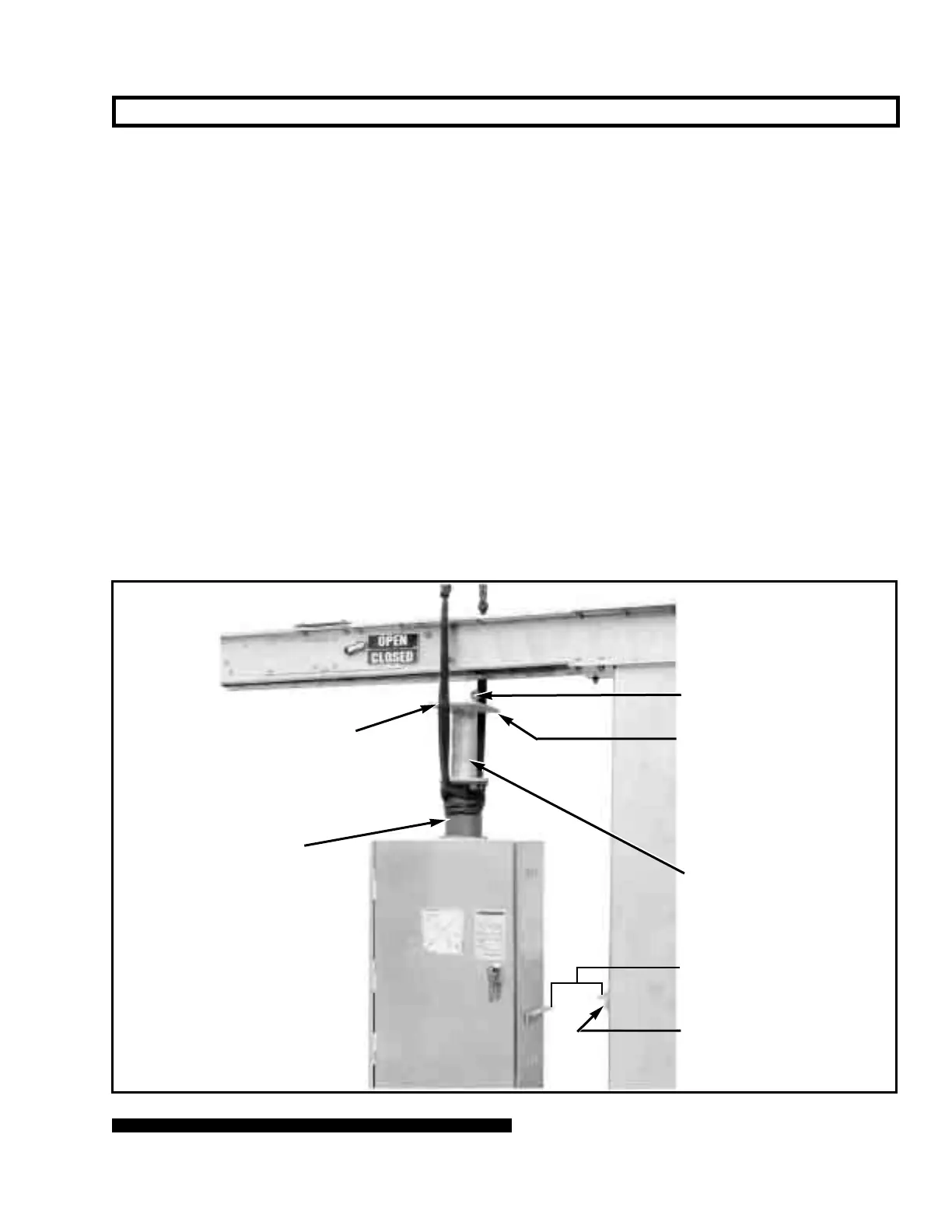

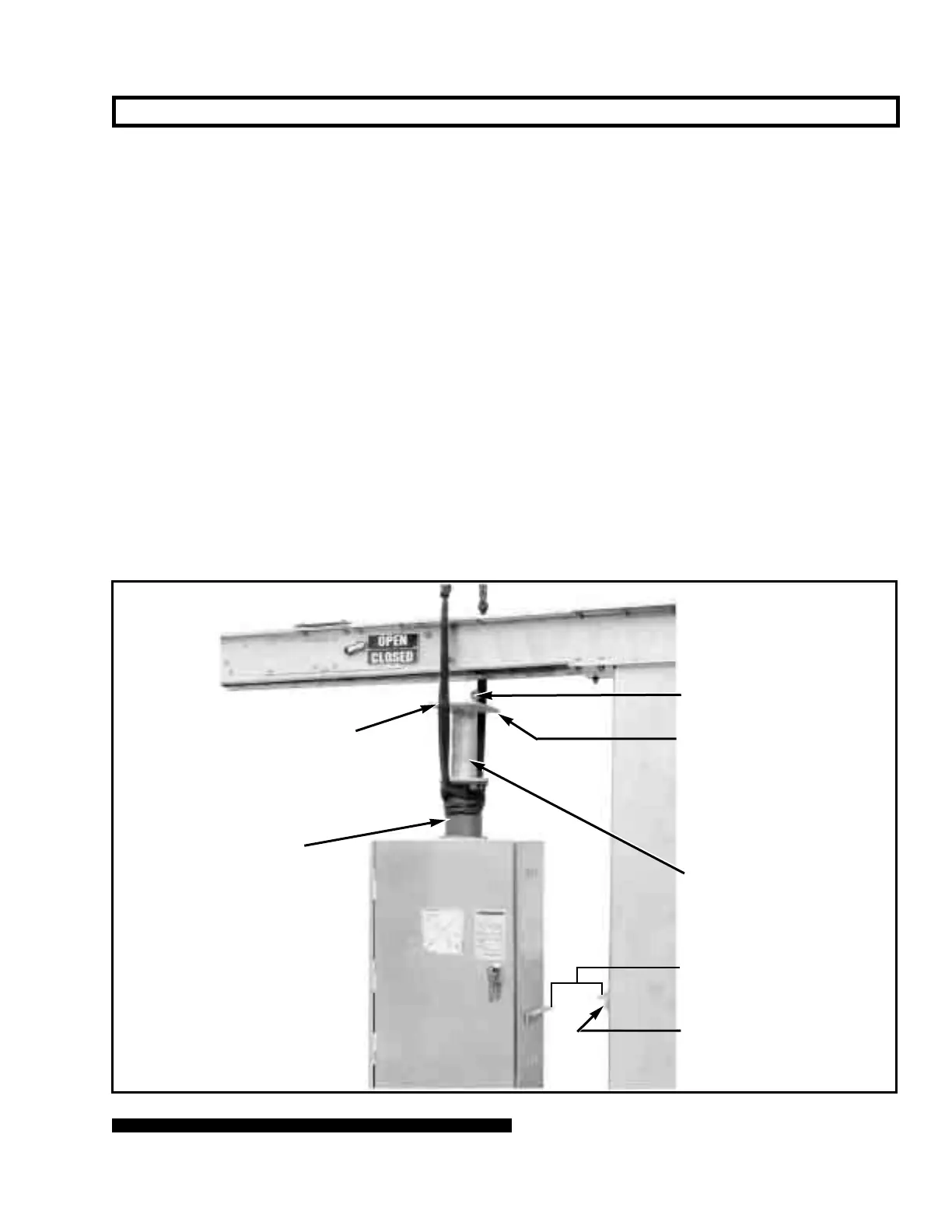

Figure 6. Hoisting operator into position.

Step 10

Attach the operator support angle to the appropriate

mounting pedestal using two ⁵⁄₈—1114 hex-head galva-

nized steel cap screws, four flat washers, and two self-

locking hex nuts furnished. Refer to the catalog drawing

and Figure 6. Then attach the operator support plate to

the angle on the side of the operator enclosure and to the

operator support angle on the mounting pedestal using

four ¹⁄₂—131¹⁄₂ hex-head galvanized steel cap screws,

flat washers, and self-locking hex nuts furnished. Securely

tighten the screws. See Figures 1 and 6. On Circuit-

Switchers utilizing two or three mounting pedestals,

insert the hole plugs furnished into all unused holes in the

pedestals.

Step 11

Attach the support arms to the mounting pedestals as

shown on the catalog drawing, using ⁵⁄₈—111¹⁄₂ hex-

head galvanized steel cap screws and flat washers fur-

nished. The screws should only be loosely attached at this

time.

Step 12

For Circuit-Switchers rated 69 kV through 138 kV: Refer

to the catalog drawing and attach the interrupter-end and

disconnect-end support arm channel assemblies

to the

support arms, using clip angles, ¹⁄₂—131³⁄₄ hex-head

galvanized steel cap screws, flat washers, and self-locking

hex nuts furnished.

For Circuit-Switchers rated 161 kV and 230 kV: Refer to

the catalog drawing and attach the interrupter-end and

disconnect-end support arm channel assemblies to the

support arms, using clip angles, ¹⁄₂—131³⁄₄ hex-head

galvanized steel cap screws (at the outboard pole-units),

¹⁄₂—132 hex-head galvanized steel cap screws (at the

center pole-unit), flat washers, and self-locking hex nuts

furnished.

Level the support arm channel assemblies to the same

elevation as the cross base, then tighten the associated

cap screws securely. Now securely tighten the

⁵⁄₈—111¹⁄₂ hex-head galvanized steel cap screws which

attach the support arms to the mounting pedestals.

Torque the cap screws to 160 foot-pounds.

A single support arm and support arm channel assembly are used on

69-kV Circuit-Switchers with 48-inch phase spacing, for attachment at the

interrupter end. Further, a disconnect-end support arm angle is furnished

in lieu of a disconnect-end support arm channel assembly.

Operator support tube

mounting plate

Uni-ball coupling

Operator support tube

Stored-energy housing

Holes for ¹⁄₂—131³⁄₄

hex-head galvanized steel

cap screws, flat washers,

and self-locking nuts

⁵⁄₈—1114 hex-head

galvanized steel cap

screws, flat washers, and

self-locking nuts

Operator support angles

Loading...

Loading...