Installation

12 S&C Instruction Sheet 716-500

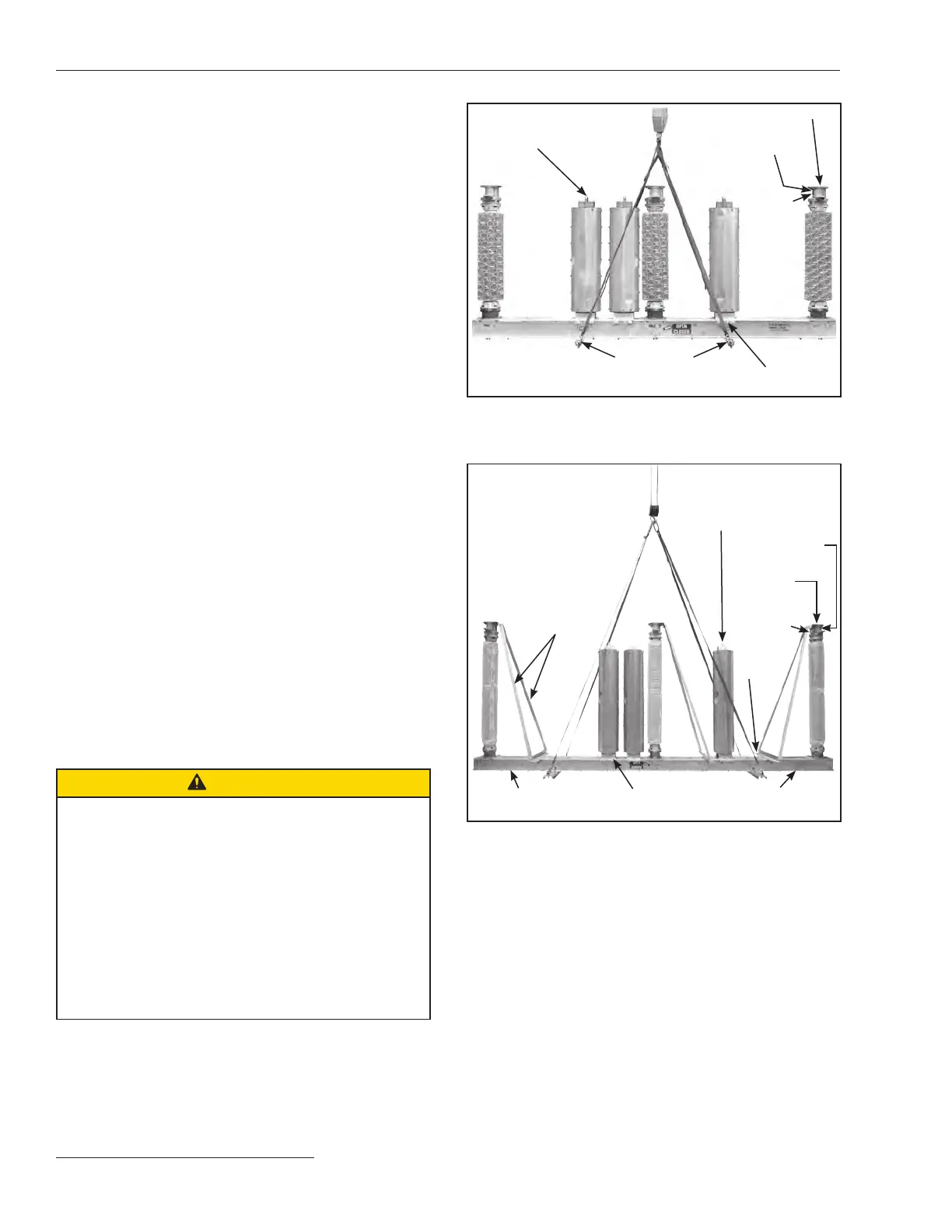

STEP 3. For circuit-switchers rated 69 kV through 138 kV:

Attach the lifting angles to the circuit-switcher

base using ½-13 x 1¼ hex-head galvanized steel cap

screws, at washers, and nuts furnished. See

Figure 5. Securely tighten the cap screws, and then

attach four suitable lifting slings to the lifting an-

gles. Unbolt the base from the shipping skids and

lift the base—with interrupters and insulating

support columns attached—on top of the mounting

pedestals as shown on the catalog drawing. Avoid

sudden starts and stops. Verify that the SWITCH-

POSITION indicator on the base is visible on the

desired side. (This is also the side on which the

operator door will open.) See Figure 5.

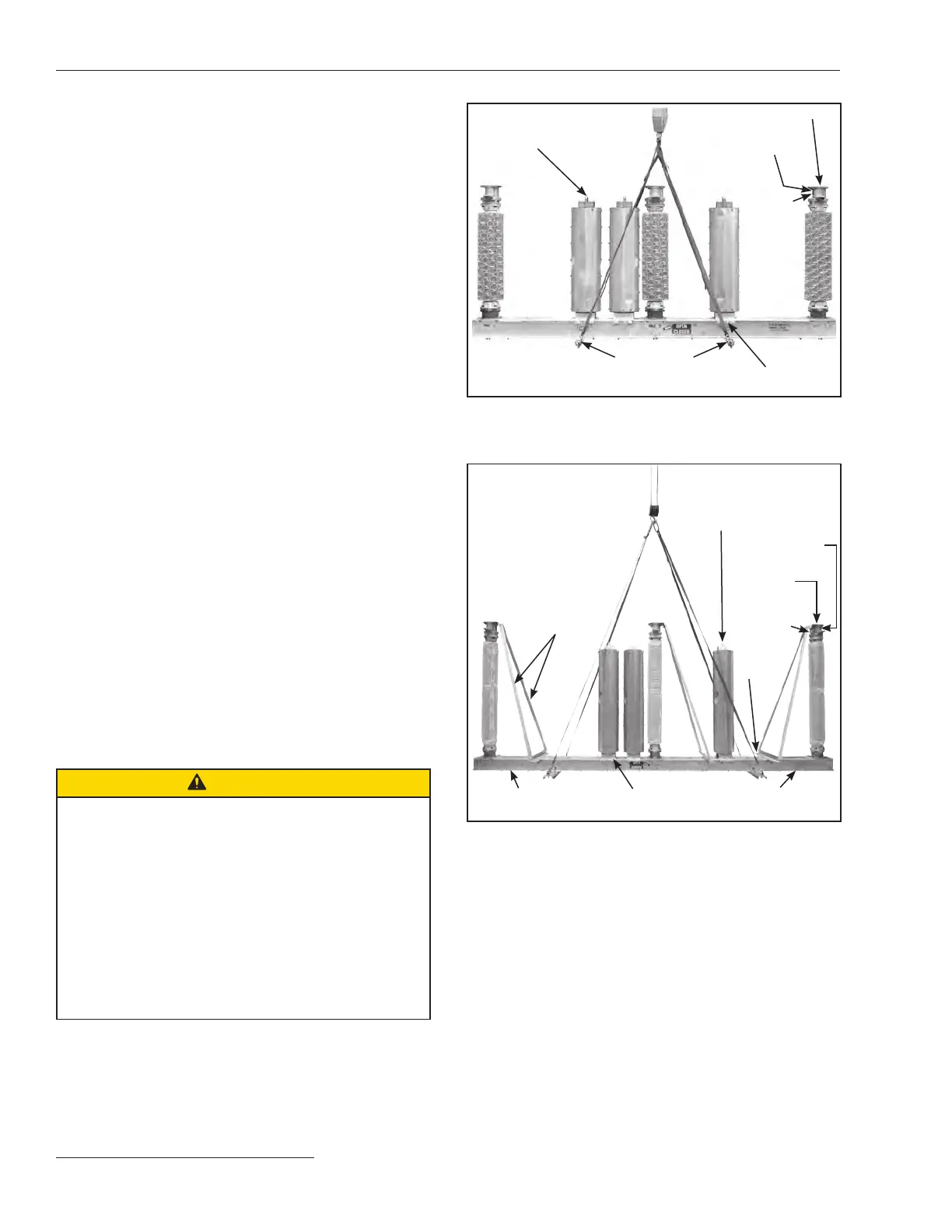

For Circuit-Switchers rated 161 kV and 230 kV:

Attach four suitable lifting slings to the eyebolts

connected to the two inboard shipping channels.

See Figure 6. Unbolt all four shipping channels

from the shipping supports. Also unbolt and dis-

card the two outboard shipping channels from the

circuit-switcher base, as shown in Figure 6, but

retain the associated ½-13 x 1¾ galvanized steel

cap screws, flat washers, and nuts. Do not unbolt

the two inboard shipping channels from the circuit-

switcher base. Now, lift the base—with interrupters

and insulating support columns attached (including

the support angles and support braces for the insu-

lating support columns)—on top of the mounting

pedestals, as shown on the catalog drawing. Avoid

sudden starts and stops. Verify that the SWITCH-

POSITION indicator on the base is visible on the

desired side. (This is also the side on which the

operator door will open.) See Figure 6.

Remove and discard the three sets of support

angles and their associated hardware. Also remove

and discard the three support braces and their asso-

ciated hardware. Leave the shipping covers on top

of the insulating support column transition boxes.

CAUTION

The operator directly drives the interrupters open and

closed through a high-speed power train leading from

the top of the operator, through a horizontal interphase

linkage enclosed in a steel-sheathed box-type base, to

reciprocating-action insulated operating rods that pass

through the center of the insulating support columns.

Permanently lubricated bearings are used throughout

the power train. The high-speed base has been fully

pre-assembled and adjusted at the factory. DO NOT

disassemble the high-speed base or high-speed

power train. Damage to the high-speed base and

personal injury may result.

Interrupter lifting

bracket

Shipping cover

Access

cover

Transition box

Lifting angle

Interrupter shipping bracket

and clamps

Figure 5. Hoist the high-speed base using a crane, 69-kV through

138-kV circuit-switchers.

Support angle

Interrupter lifting bracket

Access

cover

Shipping

cover

Transition

box

Support

brace

Outboard shipping

channel (removed)

Outboard shipping

channel (removed)

Interrupter shipping

bracket and clamps

Figure 6. Hoist the high-speed base using a crane, 161-kV and

230-kV circuit-switchers.

Loading...

Loading...