Installation

16 S&C Instruction Sheet 716-500

STEP 11. Attach the interrupter to its insulating support

column as follows:

(a) Remove and discard the shipping cover on top of

the transition box. See Figure 11 on page 14, inset.

(b) Thoroughly wire-brush the top of the transition box

and mating surface on the interrupter, and

immediately apply a liberal coating of Burndy

Penetrox® A (available from Burndy Corporation)

or equivalent aluminum-connector compound to

the brushed surfaces.

(c) Remove the four 5∕16-18 × ¾ hex-head stainless-steel

cap screws used to attach the access cover to the

side of the transition box. Remove the cover and

place it and the hardware on a clean surface. See

Figure 11 on page 14. Also remove the cloth bag

containing the hardware that will be used for con-

necting the interrupter coupling to the operating

rod link in Step 11(f).

(d) Make certain the positioning mark stamped on the

bottom of the interrupter is aligned with the

position mark stamped on the top of the transition

box. See Figure 14.

(e) Lower the interrupter onto the transition box. One

of the ½-13 stainless steel studs on the interrupter

is longer than the other three to aid in aligning the

interrupter with the transition box. Reattach a

½-inch Belleville washer and a ½-12 stainless steel

hex nut, retained from Step 9, to each of the four

studs. Lubricate the nuts to facilitate tightening.

Tighten each nut securely.

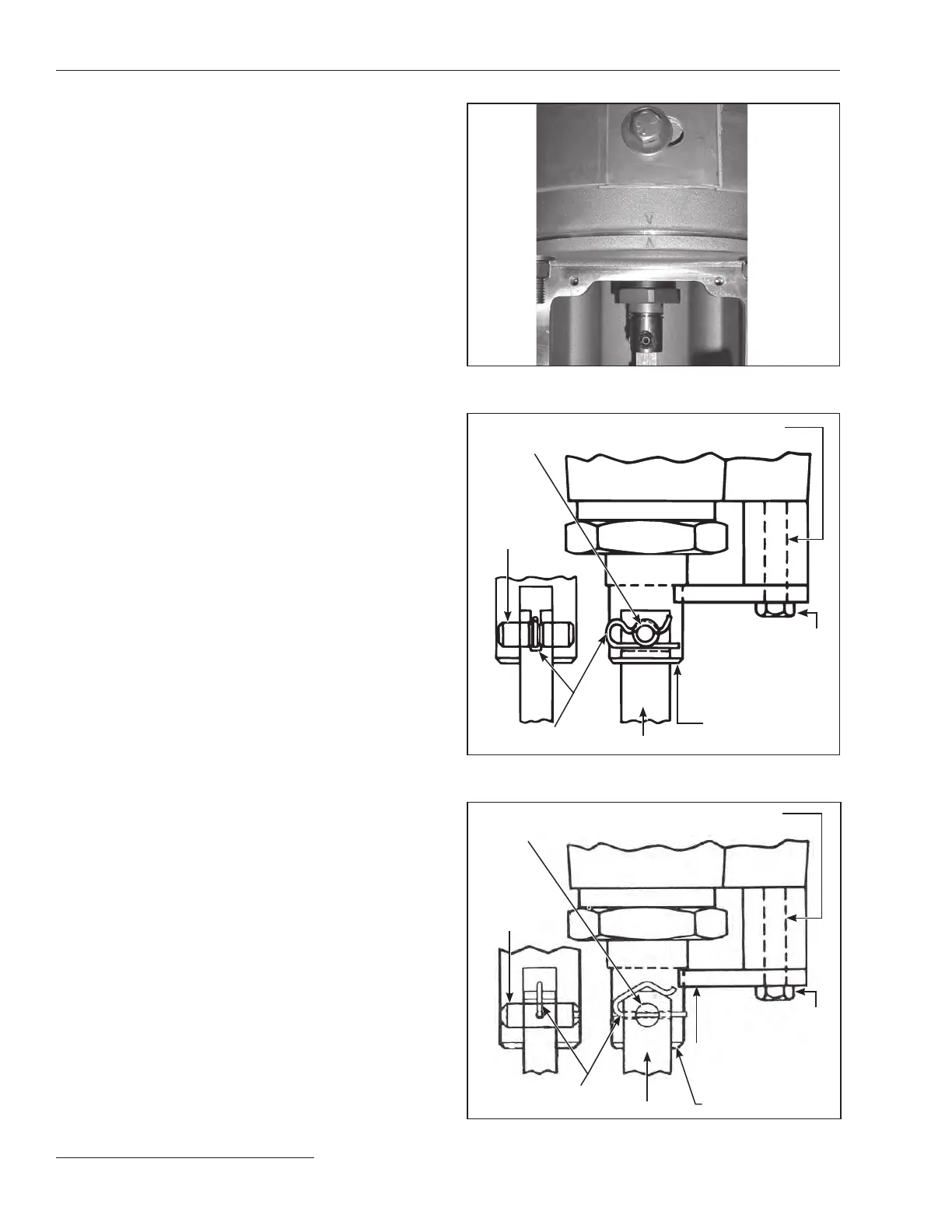

(f) For circuit-switchers rated 69 kV through 138 kV:

Insert the connecting pin retained from Step 10(c)

into the coupling and operating rod link. See

Figure15. It will be necessary to loosen the 5∕16-18 ×

2¼ hex-head stainless steel screw indicated in

Figure 15 and withdraw it approximately ⅛-inch so

the connecting pin can be inserted. Do not remove

the screw at this time. Insert the pin retaining clip

as indicated in Figure 15. Make sure that the clip is

positioned as shown.

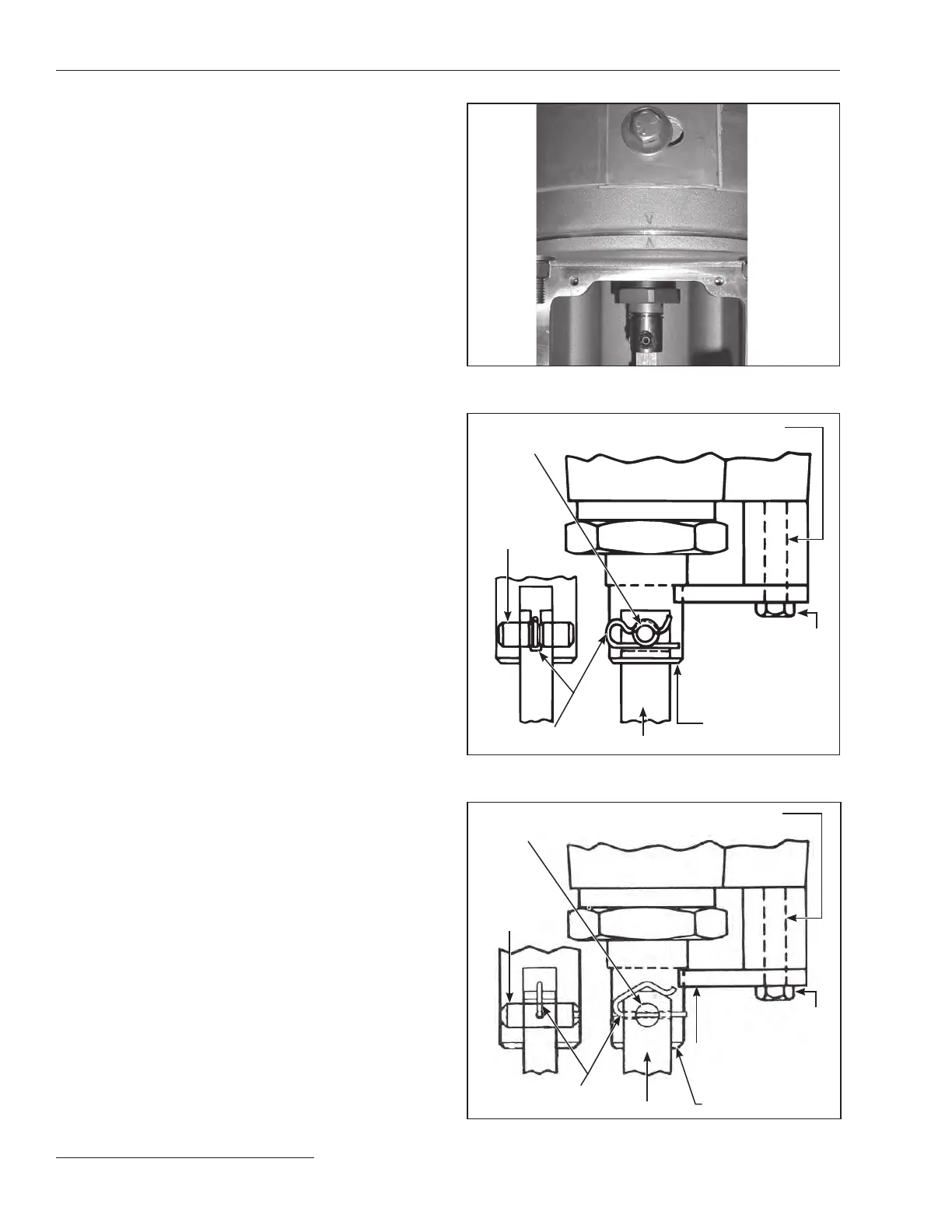

For circuit-switchers rated 161 kV through

230kV: Insert the connecting pin retained from Step

10(c) into the coupling and operating rod link. See

Figure 16. It will be necessary to loosen the 5∕16-18

× 2¼ hex-head stainless steel screw indicated in

Figure 16 and withdraw it approximately ⅛-inch, so

the connecting pin can be inserted. Do not remove

the screw at this time. Use a flat-head screwdriver

blade in the slot at the end of the connecting pin to

align with the cross-hole in the operating rod link.

Now, insert the pin retaining clip as indicated in

Figure 16. Make sure the clip is positioned as shown.

(g) Remove and discard the 5∕16-18 × 2¼ hex head

stainless steel screw, stop bracket (marked with a

black/yellow striped label), and spacer (marked

with a black/yellow striped label) illustrated in

Figures 15 and 16.

Figure 14. Align the positioning mark on the interrupter with

the mark on the transition box.

Spacer (marked with a

black/yellow striped label)

Connecting

pin

Pin retaining clip

Operating rod link

Coupling

Stop bracket (marked

with a black/yellow

striped label)

Slot (coincides

with cross hole)

5⁄16 –182¼ hex-head

stainless steel screw

Figure 15. Connect the interrupter to the operating rod link.

(69 through 138 kV)

Connecting

pin

Operating rod link

Coupling

Stop bracket (marked

with a black/yellow

striped label)

5⁄16 –182¼ hex-head

stainless steel screw

Slot (coincides

with cross hole)

Pin retaining clip

Spacer (marked with a

black/yellow striped label)

Figure 16. Connect the interrupter to the operating rod link.

(161kV and 230 kV)

Loading...

Loading...