Separately sold parts

F - 4

2. System Configuration

ONJ pipe

45 ‹ elbow

90 ‹ elbow

ONJ pipe

Straight pipe

Slide pipe

Split halves

Exhaust gas top

Orientation of opening

Upward slope

(3/100 or greater)

Adaptor for exhaust

gas extension

500mm

or less

Support legs

With no thermal insulation

With thermal insulation

30 or more

Not contacting

Exhaust gas pipe

Thermal insulation

thickness 20 or more

Not contacting

Horizontal one directional outlet

300 or more 300 or more

600

or more

150 or more

150

or more

Down

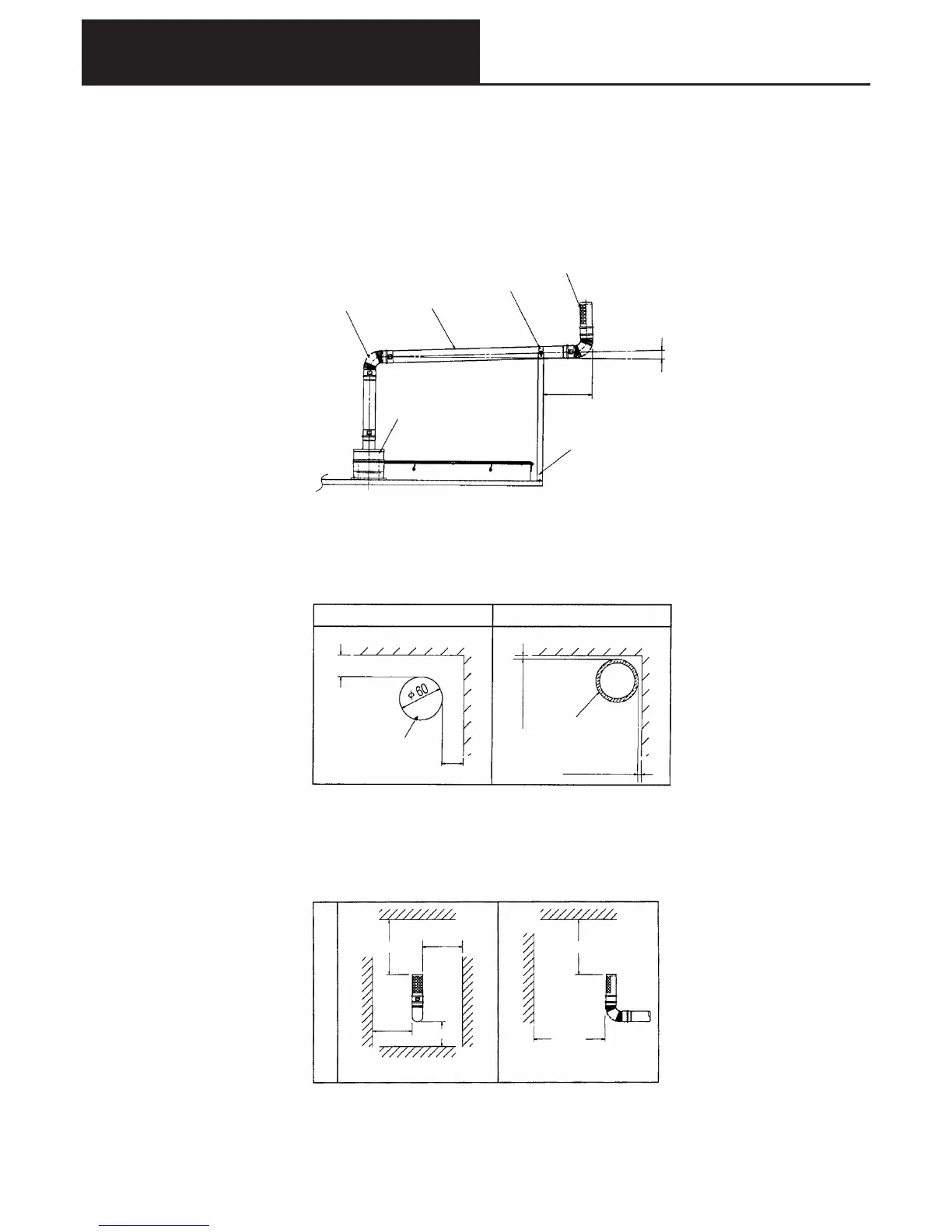

●Method of securing the exhaust gas pipe

1) For securing the exhaust gas pipe, use the installation fittings (legs, split halves) and fit on site. Using

the bolts/screws of the unit top plate secure the pipe. Refer to Figure 7 for an example.

2) Secure the exhaust gas pipe extending from the main body of the unit to the external wall or other

suitable location, using installation fittings every 1.5-2.0m.

3) The limiting distance from the final securing location to the end of the exhaust gas extension pipe shall

be 500mm or less. Refer to Figure 7.

Fig. 7

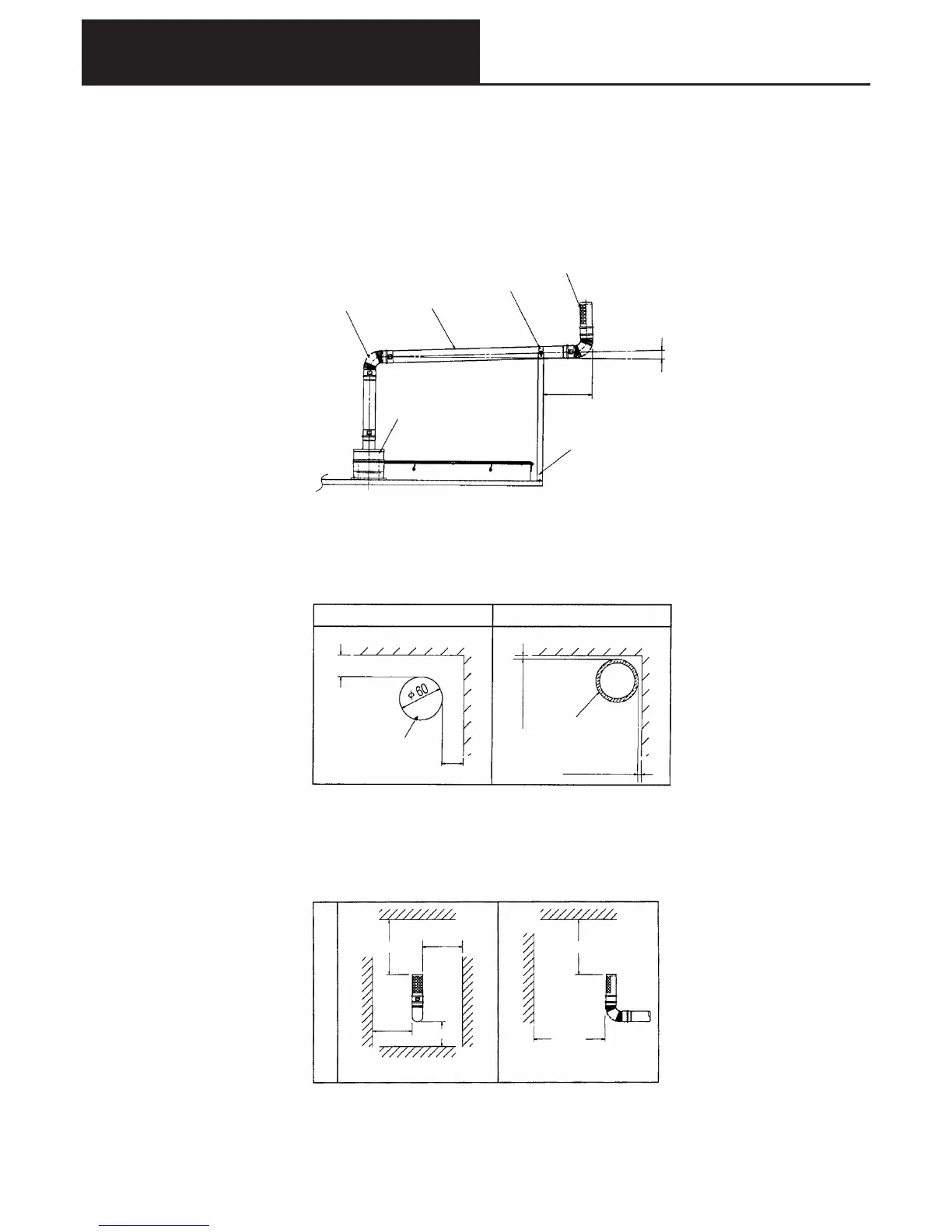

● Separation distance of the exhaust gas pipe

The separation distance (mm) of the exhaust gas pipe from “building parts with finishes made from flammable

materials, non-flammable materials, or quasi-flammable materials” shall be as shown in Figure 8.

● Separation distance of exhaust gas top

The separation distance (mm) of the exhaust gas pipe opening from “building parts with finishes made from

flammable materials, non-flammable materials, or quasi-flammable materials” shall be as shown in Figure 9.

Figure 8(Space part)

<Reference> The dimensions within the ( )are the distances for the case where a heat-proof board is installed,

and “building parts are effectively finished with non-flammable materials.

Fig. 9(Separation distance around the exhaust gas top)

Loading...

Loading...