Installation Instructions

Unpacking the Equipment

§ Please read the enclosed operating

instructions carefully before putting the

scale into operation.

§ After unpacking the equipment, please

check it immediately for any visible

damage.

$ If you detect any damage, proceed as

directed in under “Safety Inspection”

in the chapter entitled “Care and

Maintenance.”

$ It is a good idea to save the box and all

parts of the packaging until you have

successfully installed your equipment.

Only the original packaging provides the

best protection for shipment.

$ Before packing your equipment for ship-

ment, unplug all connected cables to

prevent damage.

Equipment Supplied

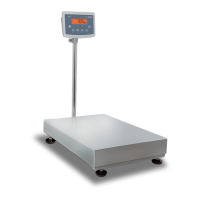

– IF.. weighing platform

– Installation and operating instructions

Requirements for the Place of

Installation

§ Observe all safety instructions.

The IF.. scale is designed to provide

reliable results under normal ambient

conditions. When choosing a location to

set up the IF.., observe the following so

that you will be able to work with added

speed and accuracy:

– Set up the IF.. on a stable, even surface.

The surface directly beneath the scale

should be smooth and dry. The load

that can be carried by the chosen work

surface must be sufficient for both the

weighing platform and any load placed

on the platform. Level the scale using

the built-in level indicator.

When moving the weighing platform, be

sure to observe safety regulations; wear

protective clothing (e.g., hardhat, steel-

toed boots, etc.).

– Avoid placing the equipment in close

proximity to a heater or otherwise

exposing it to heat or direct sunlight.

– Protect the IF.. from direct exposure

to drafts that come from open windows

or doors.

– Avoid exposing the IF.. to excessive

vibration.

– Protect the IF.. from aggressive

chemical vapors.

– Do not expose the equipment to

excessive moisture over long periods.

Turn off the power when the system

is not in use.

– The allowable operating temperature

range is -10°C to +40°C (+14°F to

+104°F).

– If there is any indication that the

equipment does not function properly

(e.g., display remains blank, or no

display backlighting) due to damage

during transport, disconnect the equip-

ment from power and notify your

nearest Sartorius Service Center; see

also: “Safety Inspection” in the chapter

entitled “Care and Maintenance.”

Shock Resistance

Even though the IF.. scales feature

highly rugged construction, there

are some limits. Avoid exposing the

system to falling objects, side impact,

or shocks.

Notes on Integration into Conveyor

Systems

Any moving or rotating parts intended

to be permanently attached to the

IF.. scale must be designed so that they

cannot affect the weighing results.

For example, rotating mechanisms must

be properly balanced.

The IF.. must be clear on all sides during

weighing so that any dirt or parts that

fall will not create a connection between

the weighing platform and any perma-

nently mounted preload components.

Make sure there are no cables or other

objects exerting force on the load plate.

Avoid generating static electricity.

Using the IF...CE in Legal Metrology

in the EU*

The type-approval certificate for veri-

fication applies only to non-automatic

weighing instruments. For automatic

operation with or without auxiliary

measuring devices or equipment, you

must comply with the regulations

applicable to the place of installation.

Conditioning the Weighing System

Moisture in the air can condense on

the surface of a cold weighing instru-

ment or other device whenever it is

brought to a substantially warmer place.

If you transfer the equipment to a

warmer area, make sure to condition it

for about 2 hours at room temperature,

leaving it unplugged from AC power.

Afterwards, if you keep the equipment

connected to AC power, the constant

positive difference in temperature

between the inside of the equipment

and the outside will practically rule out

the effects of moisture condensation.

*

including the Signatories of the Agreement

on the European Economic Area

Note:

Connection of the scale to a display

and control unit/indicator, installation,

configuration, and putting the equip-

ment into operation must be performed

by a trained dealer or Sartorius service

representative. Details on additional

settings are contained in the Sartorius

service manual.

– Unplug the power cord from the wall

socket (mains) before performing any

work on the equipment.

– The special tools indicated must be used

when performing installation.

– Installation work that affects the IP65

or IP68 protection rating must be per-

formed with extreme care.

– Any installation work that does not con-

form to the instructions in this manual

will result in forfeiture of all claims

under the manufacturer’s warranty.

– When installing the equipment in

a weighing system, the EU Directive on

Machinery (98/37/EC) must be observed.

– Make sure the junction box and load

cells do not sustain damage.

– Level the scale using the built-in level

indicator.

Note:

Make sure there is a faultless connection

between the display and control unit or

indicator and the platform (resistance:

<1 ohm). The shield must be connected

to

the cable gland on the A/D converter

and to the cable gland on the junction

box.

IP Rating

IF.. scales in the galvanized steel version

are rated to IP65; stainless steel versions

have IP68 protection. The levels of pro-

tection indicated by these ratings are as

follows:

First digit: rating 6 indicates that the

equipment is dust-tight; i.e., completely

resistant to penetration by solids. Sec-

ond digit: rating 5 indicates resistance

to penetration by water, including pow-

erful jets of water; rating 8 indicates

resistance to ingress of water during

complete, continuous submersion in

water to a depth of up to 10 meters

(approx. 32 feet).

IP65 or IP68 protection is guaranteed

only if:

– the seals on the junction box are

installed correctly in accordance with

industry standards, and

– the connecting cables, protective caps

and cable glands were installed and

connected by a qualified technician.

4

Loading...

Loading...