General system description 2 - 3

Doc.nr : 6611-018

*(1(5$/'(6&5,37,212)7+(5(027(&21752/6<67(0

The Scanreco RC 400 remote control system has been specially developed for hydraulically

driven mobile cranes and machinery. The system is a digital remote control system based on

an extremely advanced micro-processor technology. Years of exhaustive and demanding

testing have shown that the remote control system can cope with the roughest of environ-

ments.

The remote control system is tested and approved for use in, amongst others, power stations,

with a sky lift for personnel, close to work areas using blasting , on oil platforms, military

establishments or other areas with explosive environments. The system is protected against

electromagnetic and radio frequency radiation and can be installed onto all hydraulic valve

types ( voltage, current, pulse width, or protocol steered ) found on the market.

In its basic form the remote control system is comprised of a portable control unit with

manoeuvre levers for proportional control and switches for ON/OFF functions, an electronic-

box with connection cable for driving proportional electro-hydraulic slide controllers.

Digitally coded control information (lever deflection and switch position) is sent from the

control unit via electric cable, opto fibre cable or via radio to the electronicbox. The control

unit and electronicbox translate the magnitude and direction of the manouevre lever deflect-

ions and switch positions to corresponding valve function speed and direction and thus crane

movement.

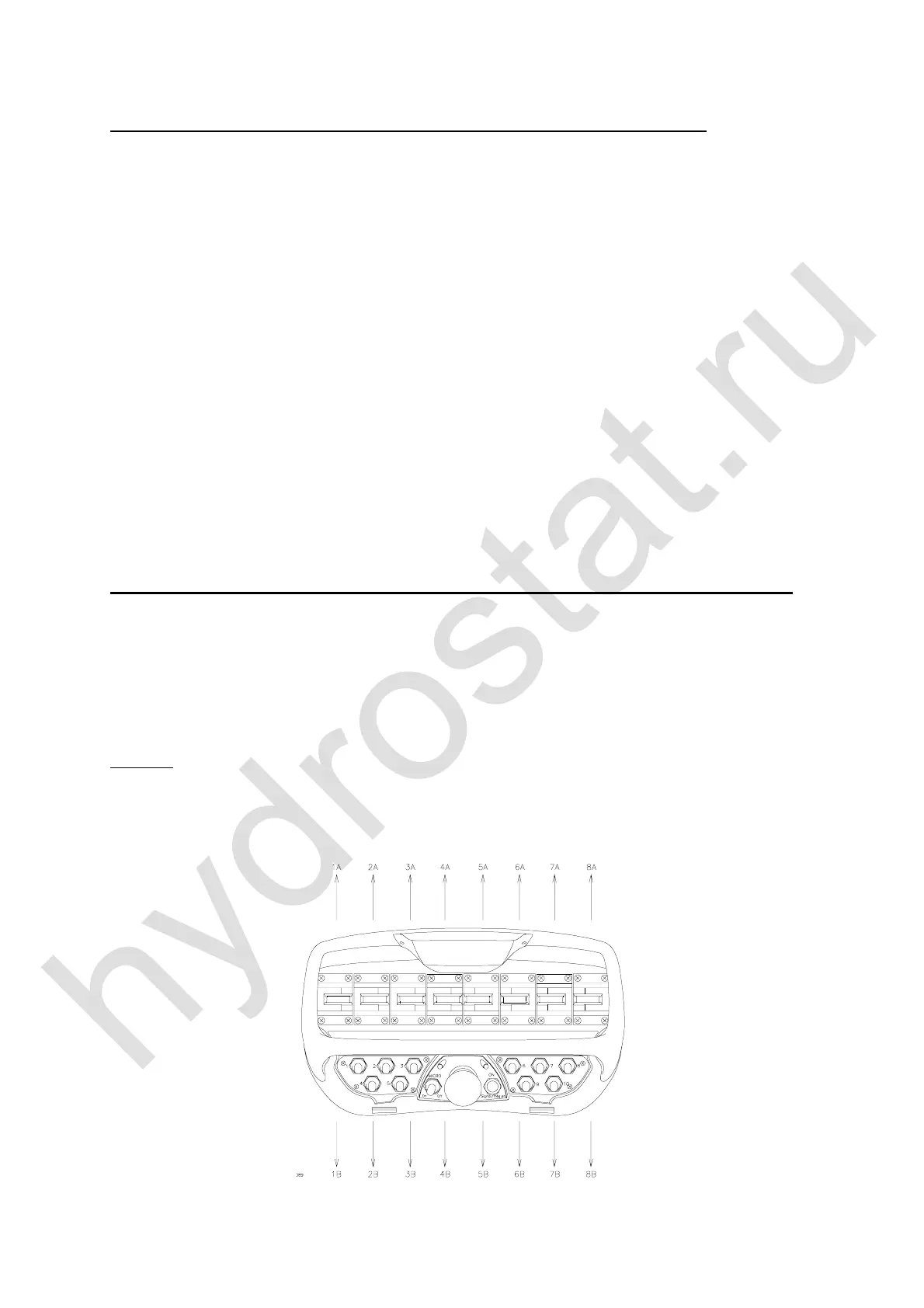

3257$%/(&21752/81,7IRUFDEOHRSWRILEUHFDEOHDQGUDGLRRSHUDWLRQ

*HQHUDOGHVFULSWLRQRIWKHSRUWDEOHFRQWUROXQLW

The portable control unit is impact and weather resistant and is light weight and compact.

Controls are available for 4, 5, 6, 7 or 8 manoeuvre functions. The manoeuvre levers are fully

proportional and have spring return to the zero position, i.e. a "dead-man’s-handle". The

control unit has an emergency stop function which will immediately stop all movement .

All manoeuvre levers are protected with a protective frame against unintentional activation

and against mechanical damage. The control unit has multi-step micro-speed operation as

standard

enabling instantaneous temporary reduction of speed and it can also be equipped

with a large number of switches for ON/OFF functions. A LED and sound signal are used to

indicate such things as operating and battery status and for a simple and diagnostic fault

finding. ( See picture of control unit ).

Loading...

Loading...