84

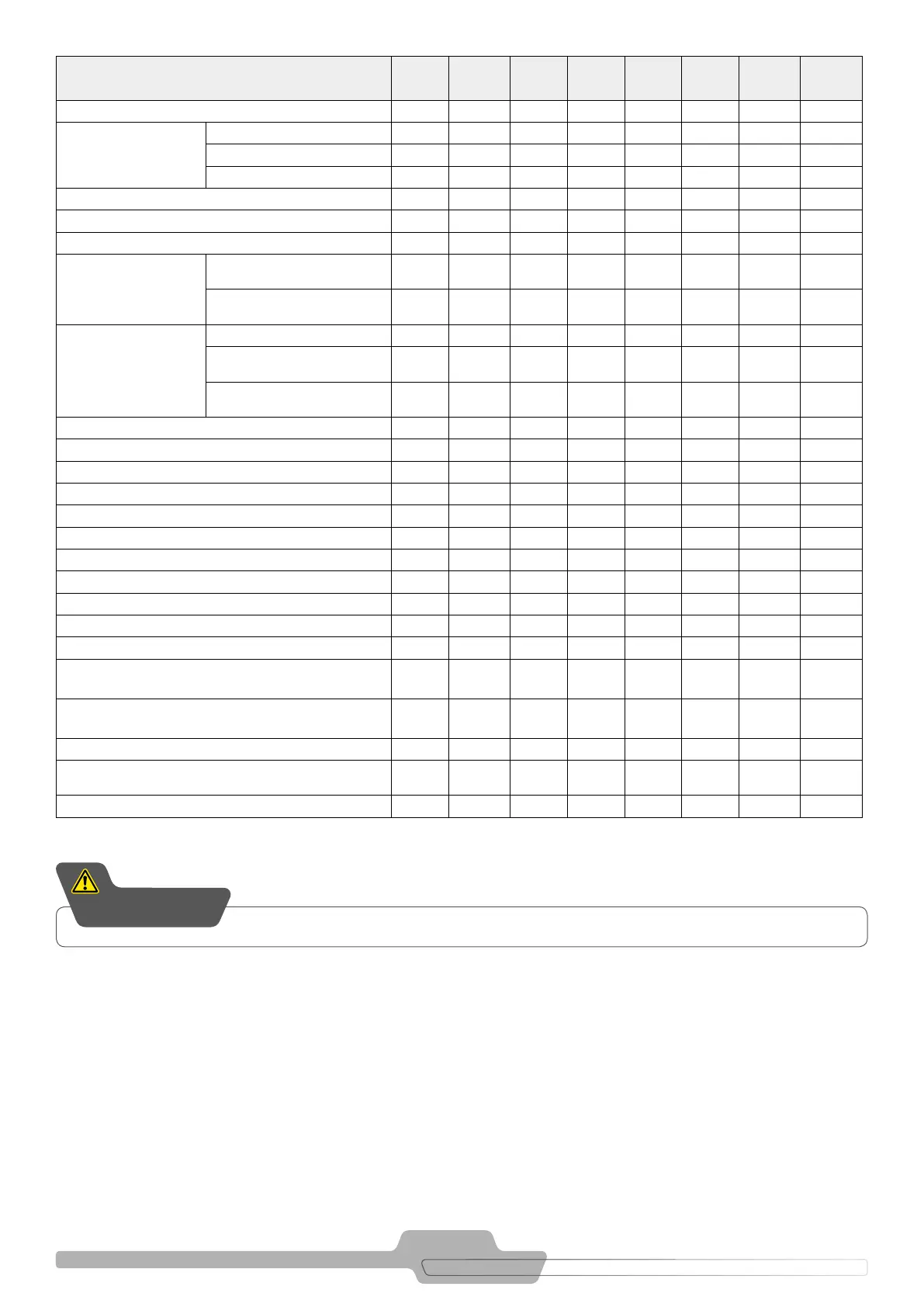

TABLE 13.3 - PREVENTIVE MAINTENANCE PLAN

Procedure Daily Weekly 1000h 2000h 4000h 8000h Annually

When

Required

Check oil level * (1)

Change lubricant oil

mineral 1000 * (8) *

mineral 4000 * (8)

synthetic 8000 * (8)

Replace the conventional air filter element * *

Replace the vehicular air filter element * *

Check the air filter element restriction level * (5)

Replace the oil filter

compressors up to 40hp

with mineral oil

* (2) (9)

compressors up to 40hp

with synthetic oil

* (2)

Replace air/oil

separator element

in compressors up to 15hp * (6)

in compressors up to 15hp

with mineral oil

* (6) (9) *

in compressors up to 15hp

with synthetic oil

* (6) *

Check the air/oil separator element restriction level * (5)

Clean the radiator and the condenser externally * (4)

Check for oil leaks *

Inspect the safety valve *

Check the condition and tightness of hoses * *

Tighten screws * (4)

Check electrical, switch and motor connections. * * *

Clean the filter air inlet on the compressor *

Compressor cleaning * *

Clean the air filters of the electrical box * *

Check voltage and tcondition of the belt(s) *

Lubricate the motor bearings (according to motor nameplate) *

Check the coalescing pre-filter restriction level *

Replace coalescing pre-filter element * (7) *

Check operation of the automatic air purge (when applicable) *

Replace nylon tubes *(11) *

If the compressor remains stopped for a period equal to or exceeding six months, it will be required and the

customer’s responsibility to replace the filters and oil.

ATTENTION

Loading...

Loading...