99

Maintenance

SP 500 / 750-15 / 750-18 / 1000 / 1250 Operation Manual

Inspect Bolts on Rams

Each day, visually inspect the bolts on the rubber rams.

If you see something unusual, shut o the engine, put

the key in your pocket and remove the waterbox cov-

ers and inspect with a wrench. If you nd that they are

loose, tighten with a torque wrench to the “Torque Spec-

ications for Metric Bolts” listed in the Appendix section.

Remember to replace the waterbox covers before using

the machine.

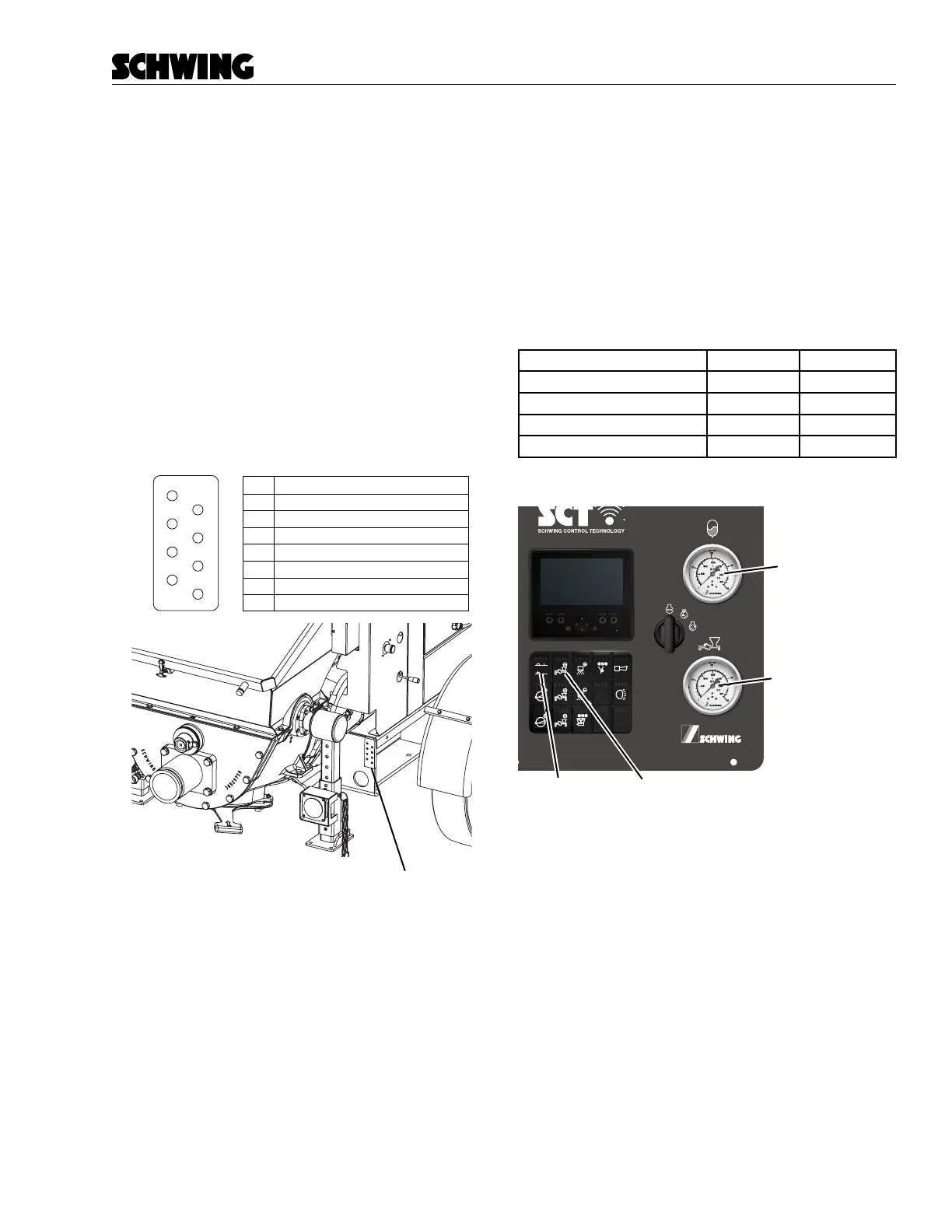

Grease the Rock Valve and Agitator Bearings

Grease the Rock Valve and agitator bearings using the

manual greasing station located on the rear, passenger

side of the stationary pump (Figure 6). If your unit was

equipped with the optional automatic greasing system,

check the grease levels each day and check for any

damage or leaks in the system.

Manual Greaser Station

Right Hand Inside Shift Cylinder

Left Hand Shift Cylinder

Right Hand Shift Cylinder

Right Hand Agitator

Left Hand Inside Shift Cylinder

Left Hand Side Agitator

Front Rock Pivot

Rear Rock Pivot

1

2

3

4

5

6

7

8

5

6

7

8

1

2

3

4

Figure 6

Agitator Grease Points

Inspect for Damage or Leaks

Visually inspect the unit for damage or leaks each day.

Repairs should be made before the unit is operated.

Check if Maintenance is due

Check your “Scheduled Maintenance Checklist” to see

if any weekly, monthly, semiannual, or annual mainte-

nance is due.

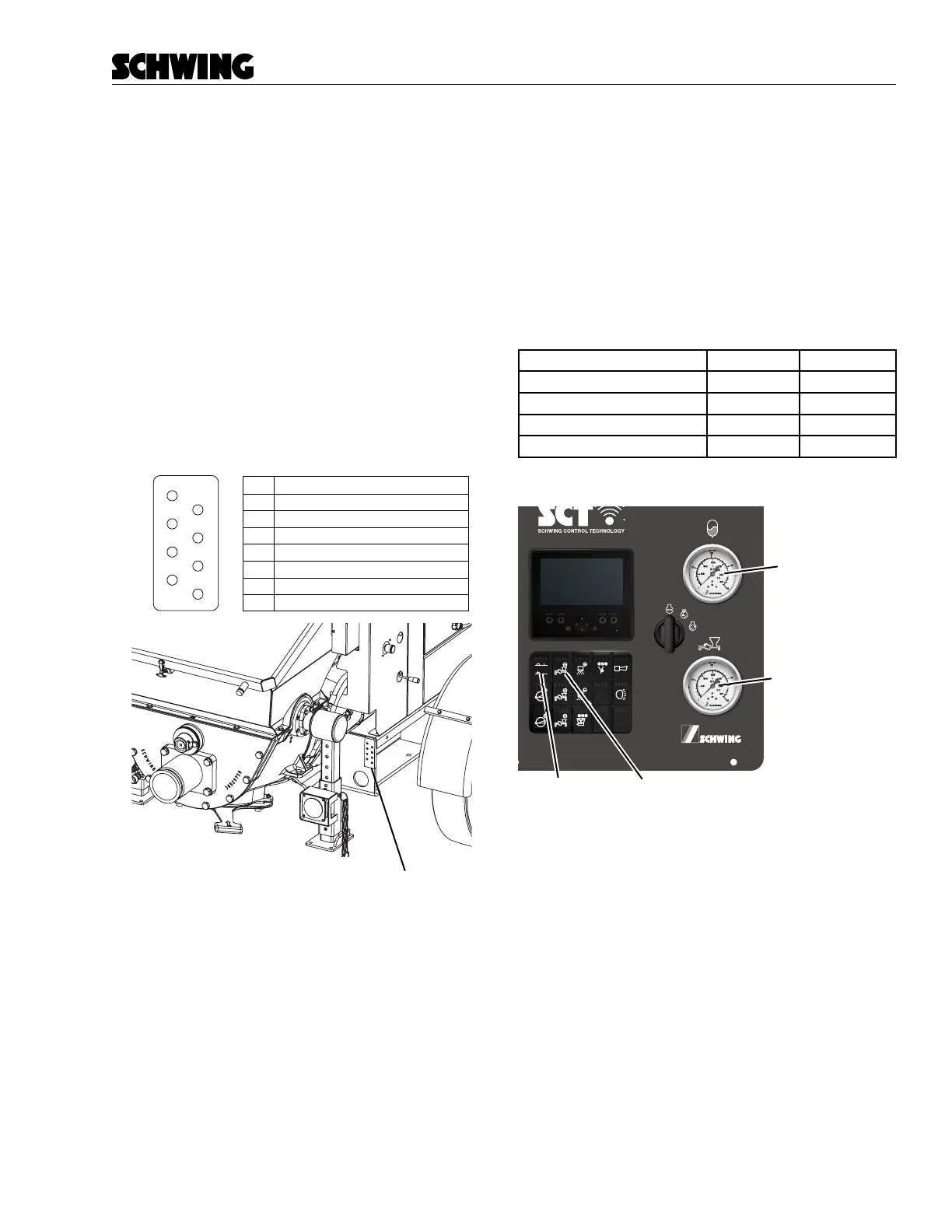

Check hydraulic pressures

Check your main pressure cut-o, soft switch and ac-

cumulator pressure cut-o settings. Pressure relief set-

tings are shown below and on the hydraulic schematic

that shipped with this unit. Changes in pressures may

indicate trouble in one or more hydraulic components.

Pressure Cut-O 300 bar

Main Relief 320 bar

Soft Switch 100 bar

Accumulator Pressure Cut-O 200 bar

ACC2ACC1

ACC3

ACC

98413629-00

Concrete Pump

Pressure Gauge

Button

Concrete Pump

Forward Button

Accumulator

Pressure Gauge

Figure 7

Rear operator panel and pressure gauges.

Loading...

Loading...