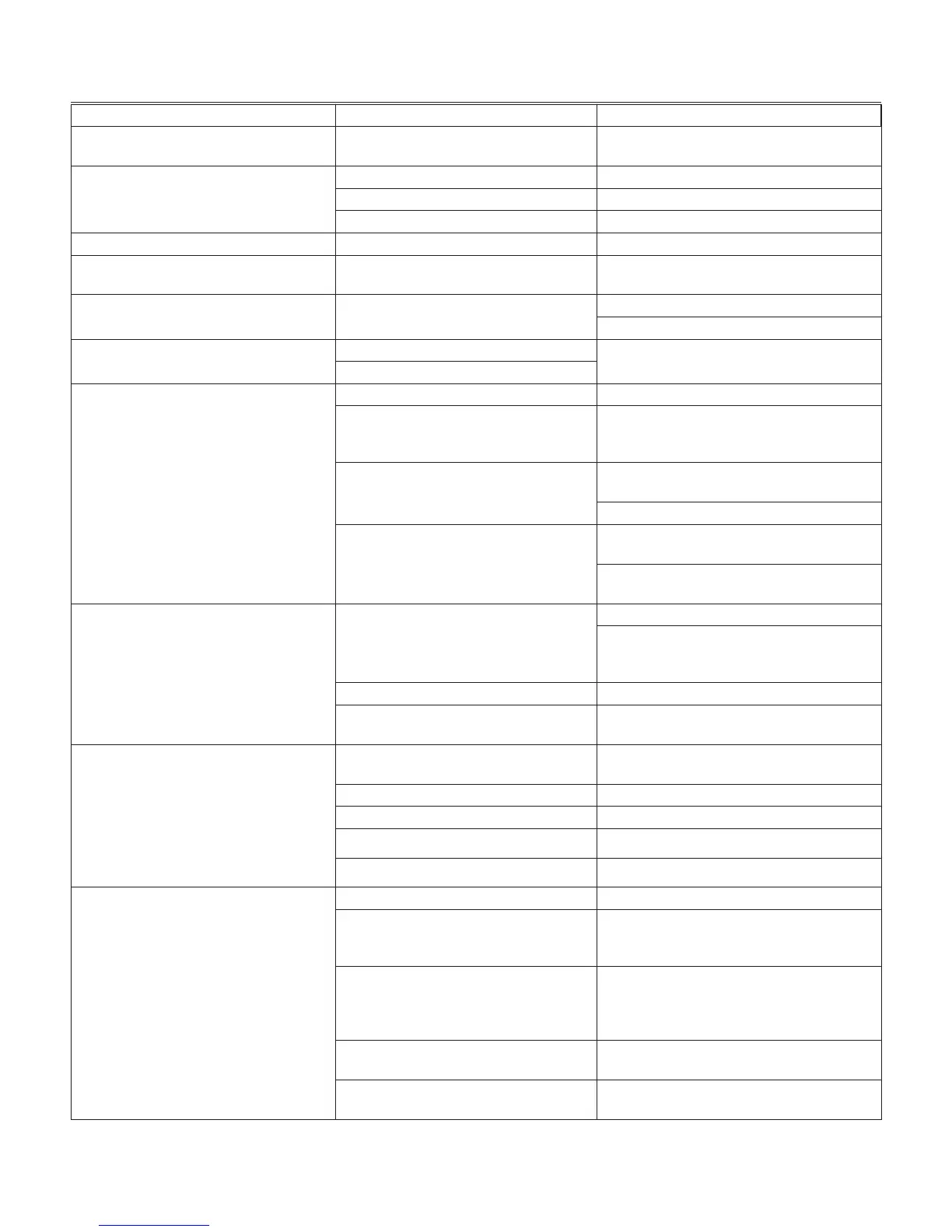

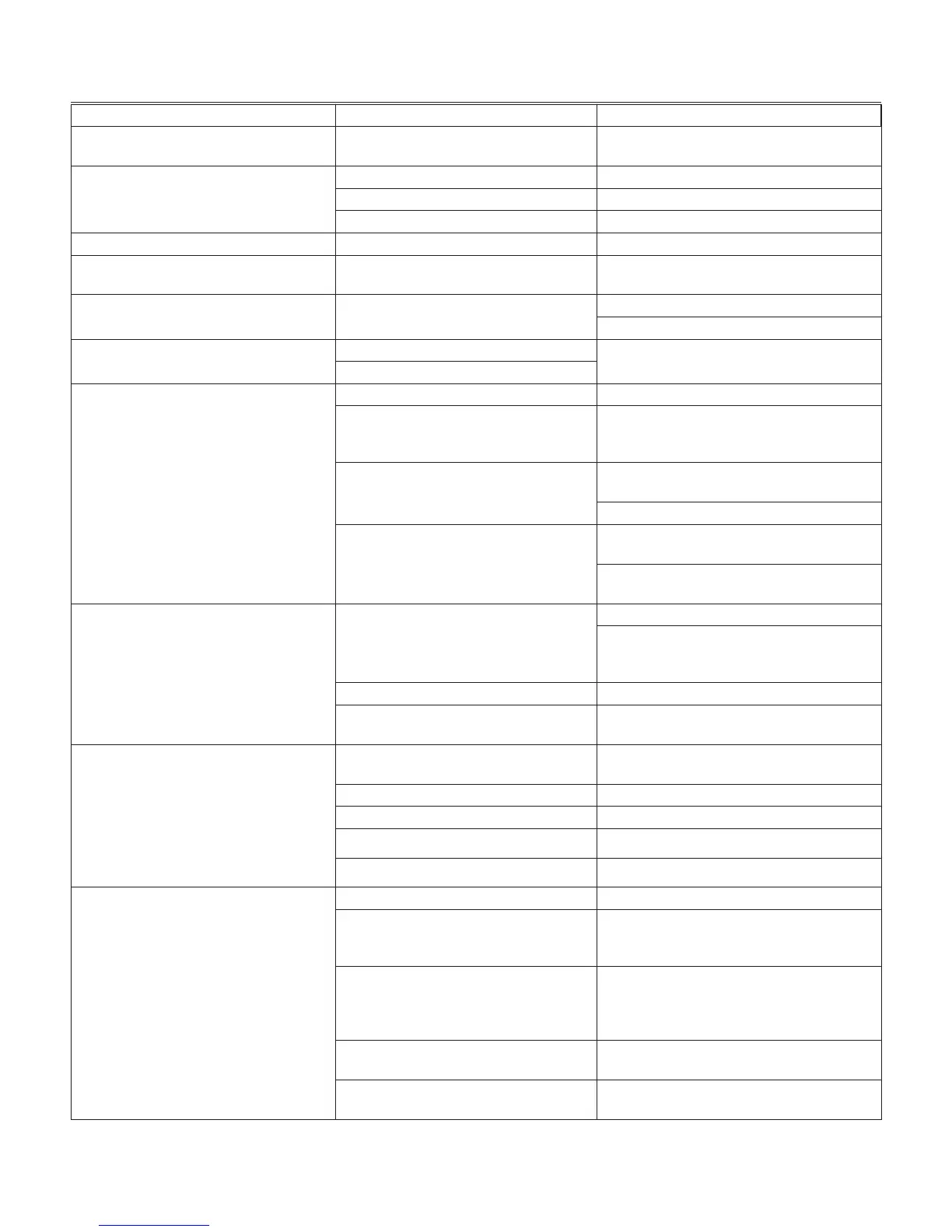

SERVICE DIAGNOSIS

SYMPTOM POSSIBLE CAUSE SUGGESTED CORRECTION

Unit will not run Blown fuse in P.C. Board Replace fuse & check for cause of blown

fuse

No LED lights Master switch in OFF position Turn switch to ON position

Inoperative P.C. Board Replace P.C. Board

Loose electrical connections Check wiring

6th Yellow LED glows Inoperative or dirty ice level control Replace or clean ice level control

5th Yellow LED glows Shortage or too soft water See remedies for shortage of water or

install a mineral salt metering device

2nd LED glows High head pressure Dirty condenser. Clean

Inoperative fan motor. Replace

3rd Yellow LED blinks Too high evap. temperature Check and charge refrigerant system

Shortage or lack of refrigerant

3rd Yellow LED glows Gear motor tends to run on reverse Check gear motor capacitor

Too low gear motor rotating speed Check rotor bearings, freezer bearings and

interior of freezer for scores. Replace

whatever is worn or damaged.

No rotation of gear motor Check for power to drive motor (16 A

fuses)

Check for stator winding

Gear motor starts and stops Check for correct operation of drive after a

while motor magnetic sensor

Check for correct magnetic capacity of

magnetic cylinder

Compressor cycles intermittently Low voltage Check circuit for overloading

Check voltage at the supply to the

building. If low, contact the power

company

Non-condensable gas in system Purge the system

Compressor starting device with loose

wires

Check for loose wires in starting device

Low ice production Capillary tube partially restricted Blow charge, add new gas & drier, after

evacuating system with vacuum pump

Moisture in the system Same as above

Low water level in the freezer Adjust to approx 20mm below ice spout

Shortage of refrigerant Check for leaks & recharge

Pitted or stained auger surface Clean or replace auger

Will not dispense Dispense motor open Check windings

No power to dispense motor Check harness connections from

touch free sensors to control board &

from board to motor

Control board does not work Trace harness from touch free

sensors to PC board, jump the two

center pins, the dispense motor

should turn. If not replace the board

Open harness Check the harness for continuity, if

any wire is open, replace the harness

Defective sensor If the above does not prove to be a

problem, replace the sensors

MDT2

May 2002

Page 19

Loading...

Loading...