Page 12 of 48P/N 595279-01 Rev. B 5/14

WARNING

DAMAGED CYLINDERS MAY SUDDENLY

LEAK OR RUPTURE IF LEFT CHARGED WITH

COMPRESSED AIR. FAILURE TO INSPECT

FOR DAMAGE AND TO EMPTY THE AIR

FROM DAMAGED CYLINDERS MAY RESULT

IN SERIOUS INJURY OR DEATH.

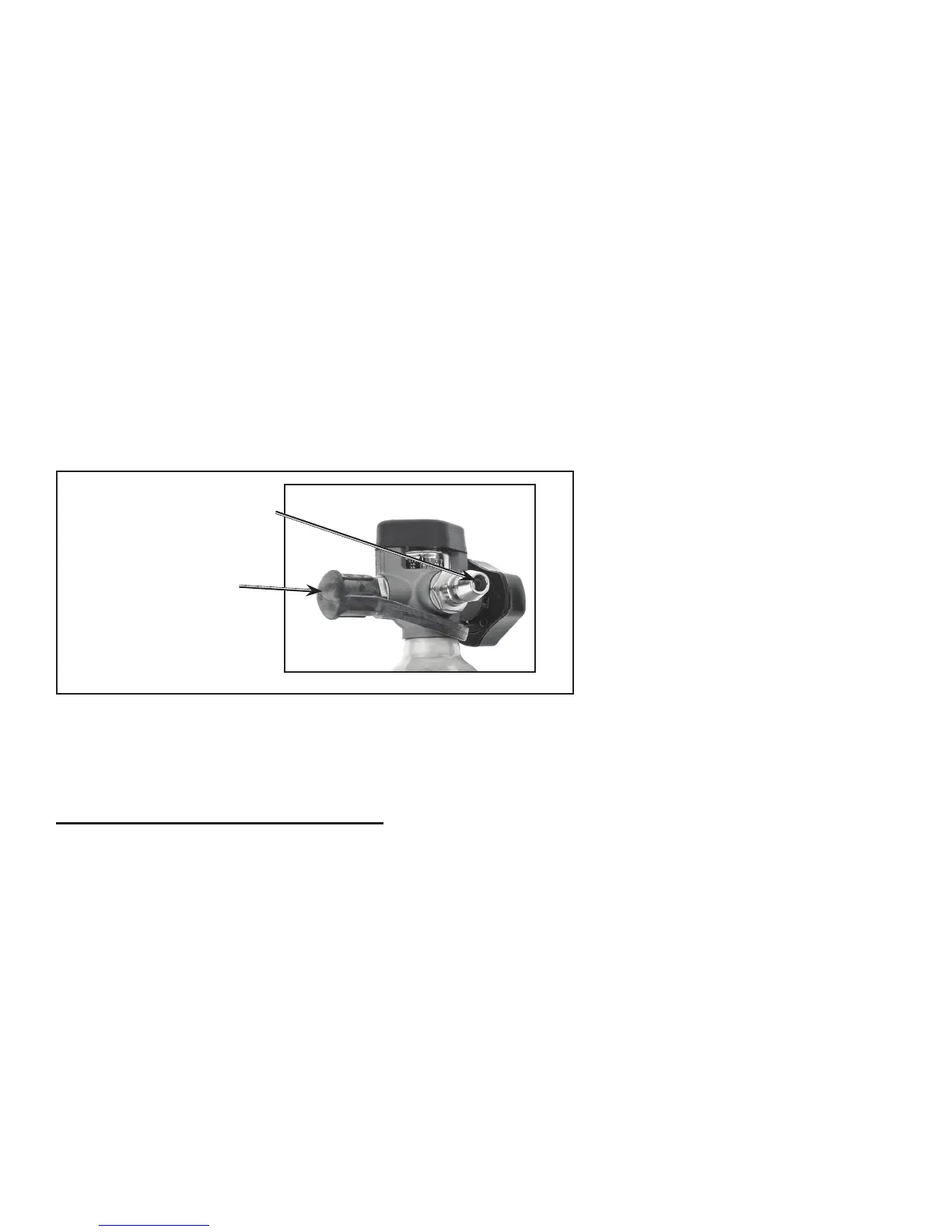

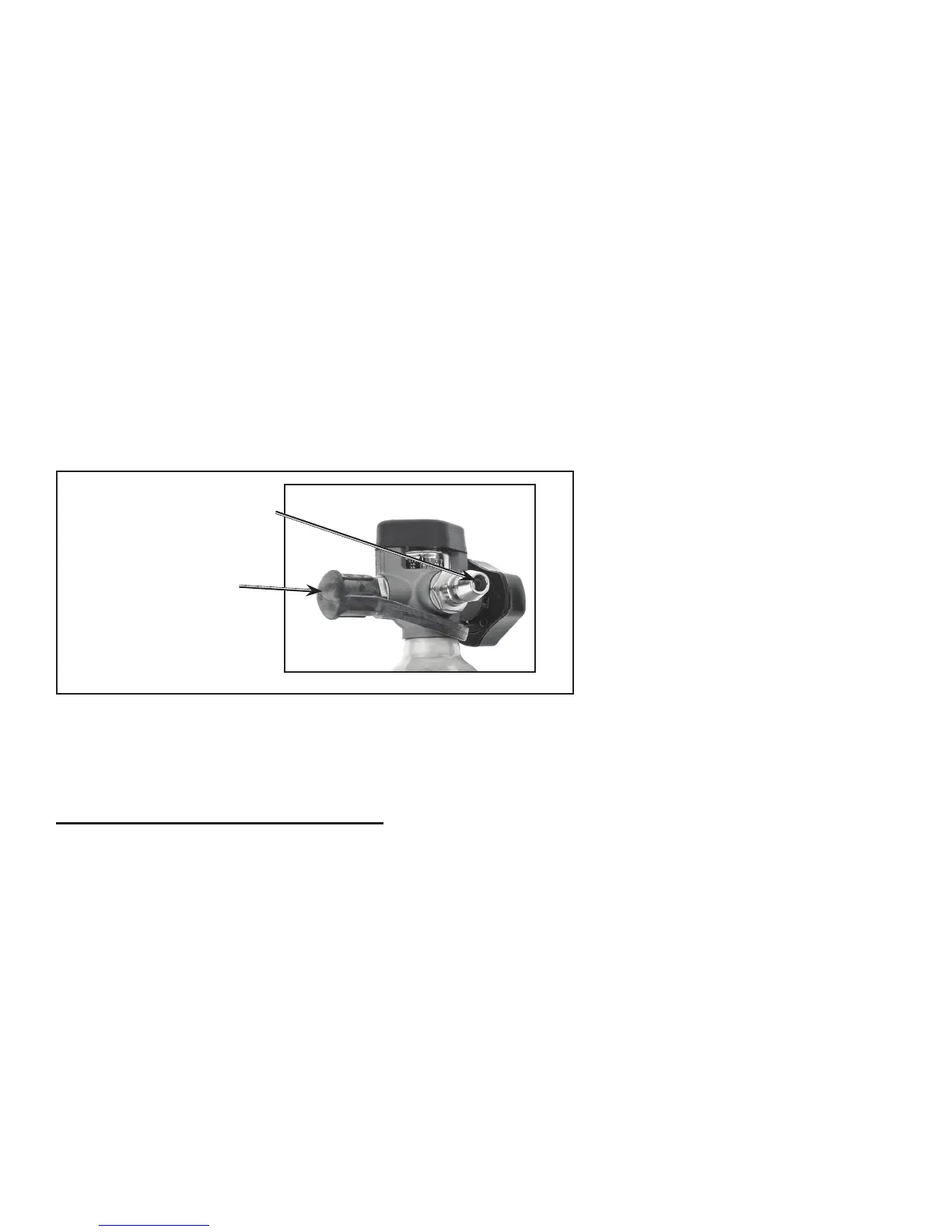

FIGURE 1

CYLINDER VALVE

2. Check the latest cylinder hydrostatic test date to ensure it is current.

The date of manufacture marked on the cylinder is also the date of

the first hydrostatic test. All breathing air cylinders used with SCOTT

AIR-PAK X3 SNAP-CHANGE SCBA’s must be visually inspected regu-

larly and hydrostatically tested at the required intervals by a licensed

cylinder retester. Intervals for hydrostatic testing are established in

the appropriate US Department of Transportation (DOT) specification

or applicable DOT exemption, or in the appropriate Transport Canada

(TC) Permit of Equivalent Level of Safety. Refer to the current revision

of Safety Precautions for AIR-PAK Cylinders, SCOTT P/N 89080-01,

available on request from SCOTT Safety. Composite fiber over-

wrapped cylinders must be tested up to their maximum life which, at

the time of the publication of this instruction, is 15 years from the date

of manufacture. It is the responsibility of your organized respiratory

protection program to arrange for visual inspection and hydrostatic

testing of cylinders by a licensed retester.

3. Inspect the cylinder valve as follows:

a) Check for damage of the cylinder valve hand wheel.

b) Inspect the cylinder valve outlet for damage. Verify that the SNAP-

CHANGE connector on the cylinder valve outlet is undamaged

and clean and free of dirt and debris.

c). Check the relief valve (burst disc) for damage or dirt.

REGULAR OPERATIONAL INSPECTION CONTINUED...

4. Check the cylinder pressure gauge for “FULL” indication. If cyl-

inder pressure is less than “FULL,” replace with a fully charged

cylinder.

RIC UAC CONNECTION INSPECTION

Inspect the RIC-UAC Connection as follows:

1. Remove the dust cap from the RIC UAC coupling on the respirator.

2. Visually inspect the coupling for dirt or damage. Remove any dirt or

contamination from the coupling.

3. If the RIC UAC coupling on the respirator appears damaged, remove

the respirator from service and tag for repair by authorized personnel.

4. If no damage is found, replace the dust cap.

VERIFY THAT THE

CYLINDER CONNECTOR

IS CLEAN AND FREE

OF DIRT OR DEBRIS

PROTECTIVE

CAP ON CGA

FILL FITTING

CYLINDER VALVE

WITH SNAP-CHANGE

ATTACHMENT

Loading...

Loading...