13

and emptied of compressed air. Refer to current applicable pub-

lications on compressed gas cylinder inspection available from

Compressed Gas Association Inc., 1725 Jefferson Davis Hwy.,

Suite 1004, Arlington, VA 22202, (703-412-0900) for a detailed ex-

planation of cylinder inspection procedures.

4. Check cylinder pressure gauge for “FULL” indication. If cylin-

der pressure is less than “FULL,” replace with a fully charged

cylinder.

5. Check to ensure reducer coupling is secure to the cylinder valve

outlet.

6. Check that the breathing regulator purge valve (red knob on regu-

lator) is closed (full clockwise and pointer on knob upward).

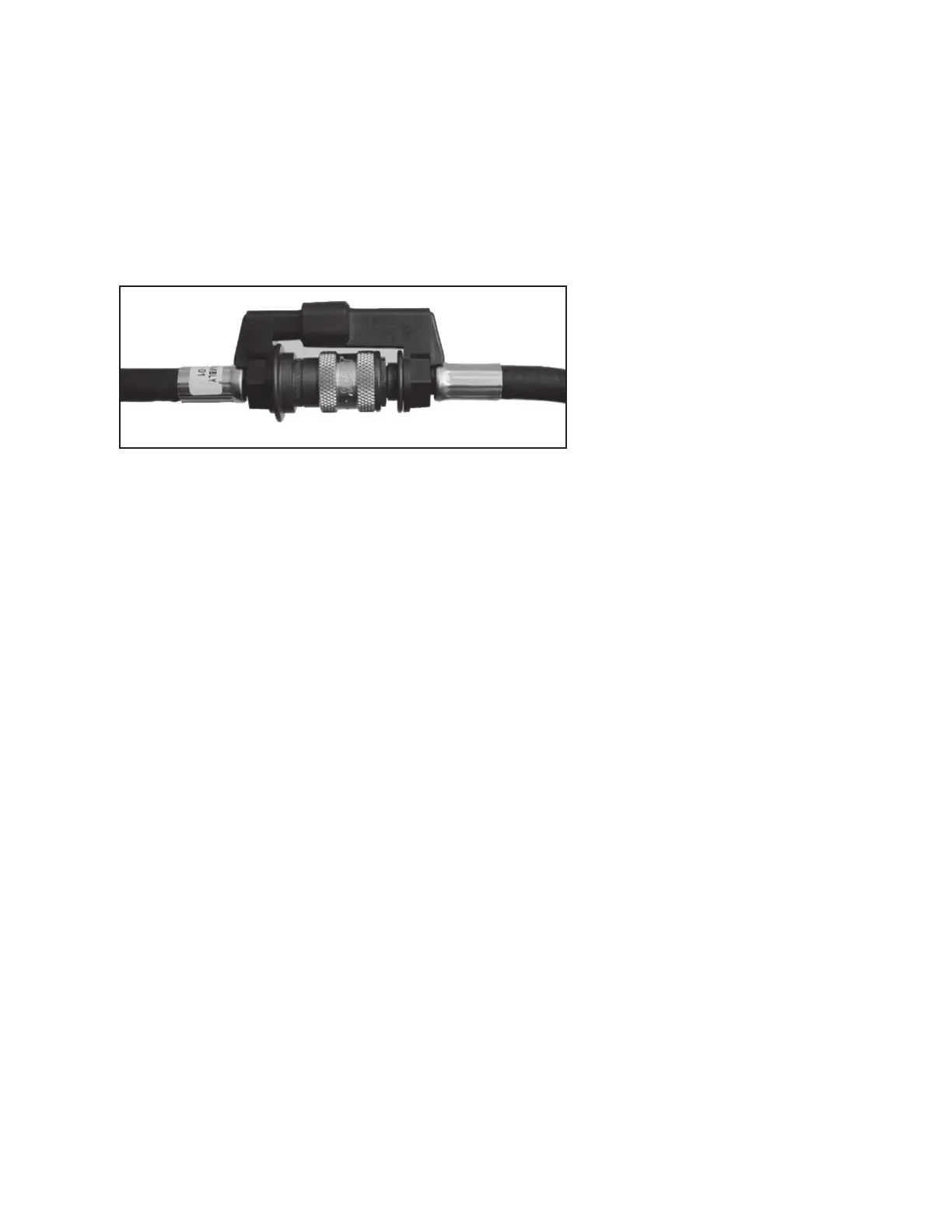

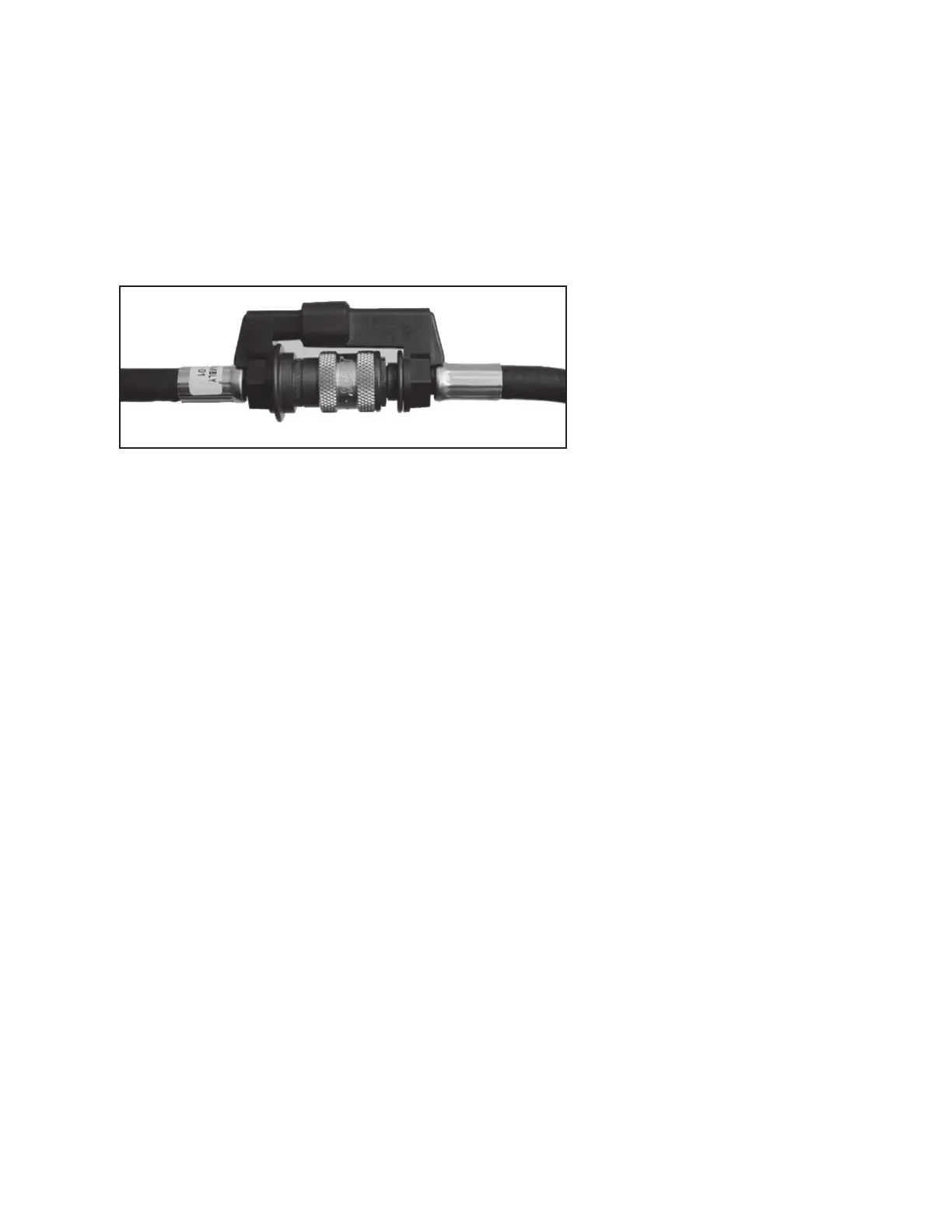

7. If the hose to the breathing regulator is equipped with a quick dis-

connect (See STANDBY INSPECTION, CLEANING AND STOR-

AGE Section for instruction on operation of the quick disconnect

coupling on regulator assemblies), check that the quick discon-

nect is engaged properly by tugging on the coupling. The Pull-back

Sleeve Quick Disconnect is shown in FIGURE 2.

8. Fully depress the center of the air saver/donning switch on the

top of the regulator and release.

9. Slowly open the cylinder valve by fully rotating knob counterclock-

wise. VIBRALERT alarm shall actuate and then stop. The HEADS-

UP DISPLAY will initialize with all five lights on for twenty seconds

followed by display of cylinder supply level. If the LOW BATTERY

light at the far right of the display remains lit or begins to flash,

replace the battery according to the BATTERY REPLACEMENT

section of this instruction before proceeding.

If the respirator is equipped with the PASS DEVICE distress alarm,

the distress alarm will be actuated when the cylinder valve is

opened. Refer to operating and maintenance instructions of the

PASS DEVICE distress alarm for the operational inspection of the

PASS DEVICE distress alarm.

10. Don the facepiece or hold the facepiece to the face to effect a

good seal. Inhale sharply to automatically start the flow of air.

Breathe normally from the facepiece to ensure proper operation.

11. Remove facepiece from face. Air shall freely flow from the face-

piece.

12. Fully depress the center of the air saver/donning switch on the

top of regulator and release. The flow of air from the facepiece

shall stop. Examine the complete respirator for air leaks. There

shall be no leakage of air from any part of the respirator.

13. Rotate purge valve 1/2 turn counterclockwise (pointer on knob

downward). Air shall freely flow from the regulator.

14. Rotate purge valve 1/2 turn clockwise to full closed position

(pointer on knob upward). Air flow from regulator shall stop.

WARNING

FAILURE TO CHECK ENGAGEMENT OF THE

COUPLING AS DESCRIBED MAY LEAD TO

HOSE SEPARATION AND LOSS OF BREATH-

ING AIR RESULTING IN SERIOUS INJURY

OR DEATH.

REGULAR OPERATIONAL INSPECTION

CONTINUED ON NEXT PAGE...

FIGURE 2

PULL-BACK SLEEVE QUICK DISCONNECT

CAUTION

DO NOT USE TOOLS TO OPEN OR CLOSE

THE PURGE VALVE. OPEN OR CLOSE BY

USING FINGER-PRESSURE ONLY. ROTA-

TION OR THE PURGE VALVE IS LIMITED TO

1/2 TURN. USE OF TOOLS TO OPEN OR

CLOSE PURGE VALVE MAY RESULT IN

DAMAGE TO THE PURGE VALVE.

Loading...

Loading...