© 2007 Security Door Controls Printed in the U.S.A. LIT-Datasheet date qty vendor

SECURITY DOOR CONTROLS

www.sdcsecurity.com service@sdcsecurity.com

[t] 800.413.8783 805.494.0622 [f] 805.494.8861

801 Avenida Acaso, Camarillo CA 93012 • PO Box 3670, Camarillo CA 93011-3670

SECURITY DOOR CONTROLS

sdcsecurity.com service@sdcsecurity.com

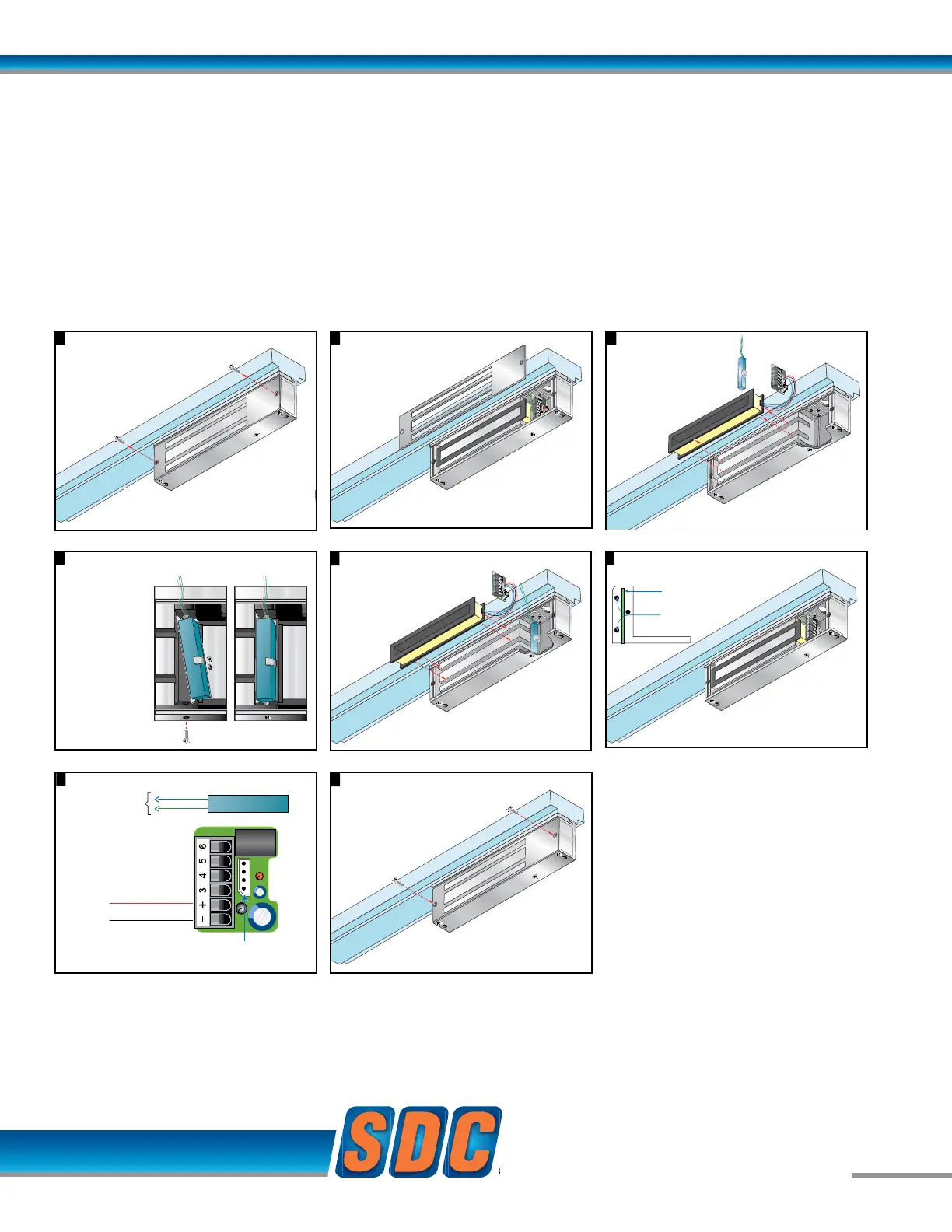

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

{

NO

COM

Cradle

Position Posts

PC Board

Input module wiring.8

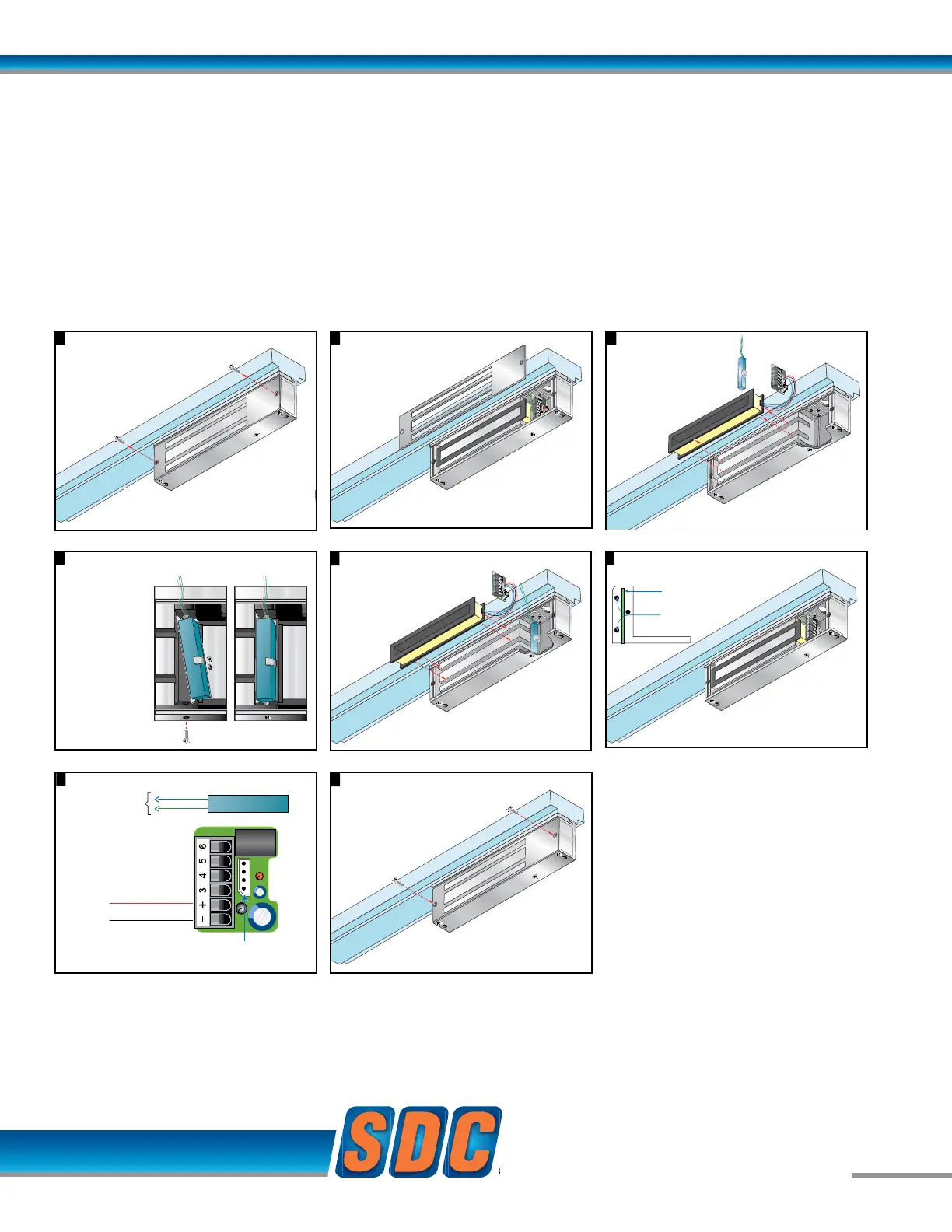

Remove cover plate screws.

1 2

Remove cover plate.

3

7

Lift input module

and magnetic coil

from the case.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

5

The Magnetic Bond Sensor

should be positioned as

shown below, after step 4.

9

Attach cover plate.

EZ-B-80 MAGNETIC BOND SENSOR

Modular Kit

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

{

NO

COM

Cradle

Position Posts

PC Board

Input module wiring.8

Remove cover plate screws.

1 2

Remove cover plate.

3

7

Lift input module

and magnetic coil

from the case.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

5

The Magnetic Bond Sensor

should be positioned as

shown below, after step 4.

9

Attach cover plate.

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

{

NO

COM

Cradle

Position Posts

PC Board

Input module wiring.8

Remove cover plate screws.

1 2

Remove cover plate.

3

7

Lift input module

and magnetic coil

from the case.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

5

The Magnetic Bond Sensor

should be positioned as

shown below, after step 4.

9

Attach cover plate.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

9

Attach cover plate.

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

Cradle

Position Posts

PC Board

Input module wiring.8

Remove cover plate screws.

1 2

Remove cover plate.

3

7

Lift input module

and magnetic coil

from the case.

Place input module vertically between post

a

t each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

5

The Magnetic Bond Sensor

should be positioned as

shown below, after step 4.

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

Cradle

Position Posts

PC Board

Input module wiring.8

Remove cover plate screws.

1 2

Remove cover plate.

3

7

Lift input module

and magnetic coil

from the case.

Place input module vertically between post

a

t each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

5

The Magnetic Bond Sensor

should be positioned as

shown below, after step 4.

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

{

NO

COM

Input module wiring.8

3

Lift input module

and magnetic coil

from the case.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

9

Attach cover plate.

B Option

Magnetic Bond Sensor

NOT USED

POWER

DPS CO

NC

NO

Magnetic Core

Connector

{

NO

COM

Input module wiring.8

3

Lift input module

and magnetic coil

from the case.

4

Place input module vertically between post

at each side of case.

Remove 1 screw

from the case

bottom.

Place the

Magnetic Bond

Sensor at the

base of the

Magnetic Core.

Secure sensor

in place with

screw as

shown.

9

Attach cover plate.

While a Door Status Sensor indicates the door is open

or closed, SDC’s Magnetic Bond Sensor provides higher

security monitoring by indicating the locked / unlocked

mode, tampering and low holding force. The use of

both the door status and magnetic bond sensor is

recommended for high security applications.

Application: Lock secure status annunciation,

mantrap system logic,

CCTV camera activation.

Output: SPDT Dry Contact,

250 mA @ 12/24VDC

Loading...

Loading...