MAINTENANCE PROCEDURES

Do not overfill.

F09D0SY

1

TYPICAL

1. Oil cap

NOTE: Every time oil is added in en-

gine, the complete procedure ex-

plained above must be done. Oth-

erwise, you will have a false oil level

reading.

9. Properly reinstall oil cap and dip-

stick.

10. Repeat procedure for the other en-

gine.

11. Wipe off any oil spillage.

Engine Oil Change and Oil

Filter Replacement

The oil change and filter replacement

should be performed by an authorized

Sea-Doo Boats dealer.

Engine Coolant

Recommended Engine Coolant

Always use ethylene-glycol antifreeze

containing corrosion inhibitors specifi-

cally for internal combustion aluminum

engines.

NOTE: When available, it is recom-

mended to use biodegradable an-

tifreeze compatible with internal com-

bustion aluminum engines. This will

contribute to protecting the environ-

ment.

Cooling system must be filled with

BRP PREMIXED COOLANT (P/N 219

700 362) or with a water and antifreeze

solution (50% distilled water, 50% an-

tifreeze).

To prevent antifreeze deterioration, al-

ways use the same brand. Never mix

different brands unless cooling sys-

tem is completely flushed and refilled.

Refer to an authorized Sea-Doo Boats

dealer.

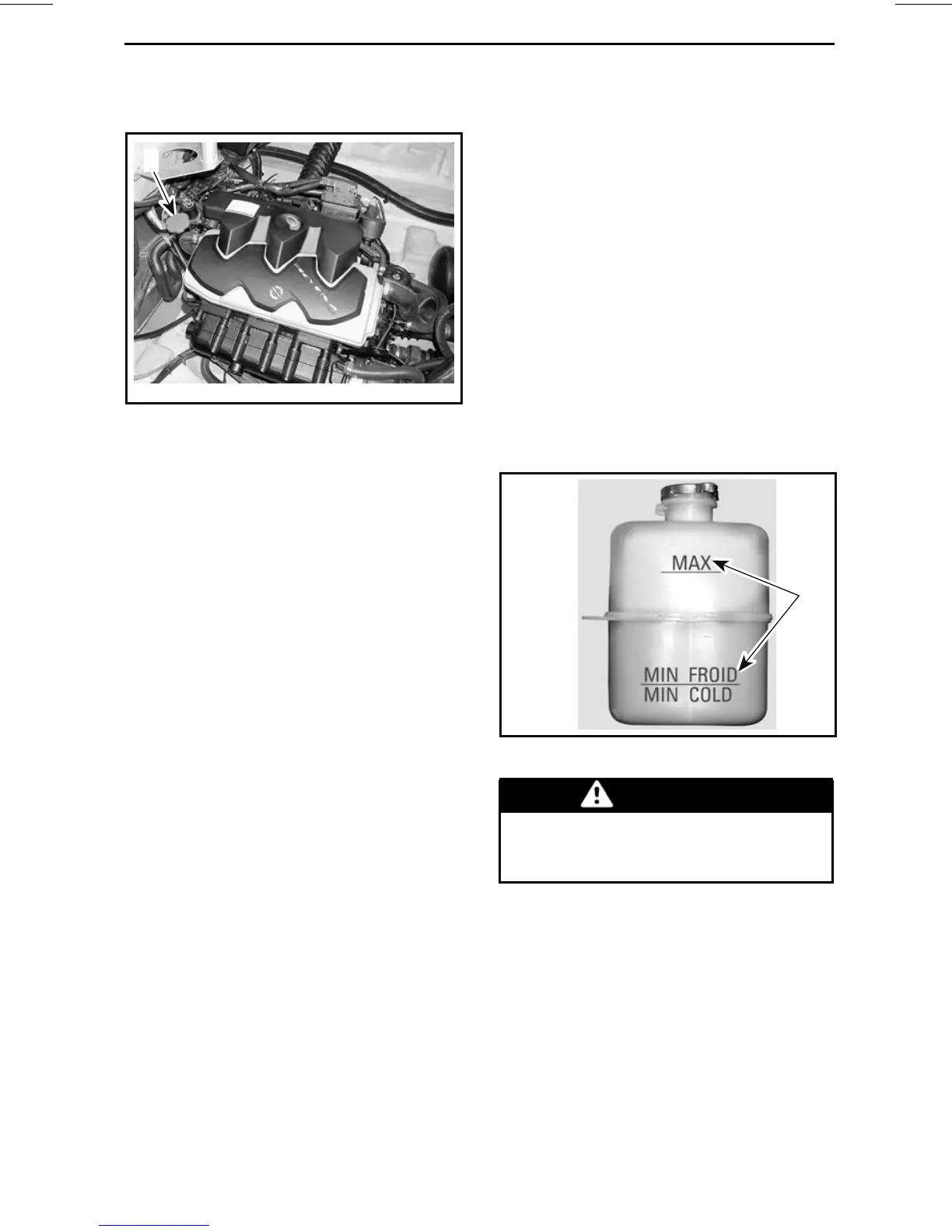

Engine Coolant Level

With boat on a level surface, coolant

shouldbebetweenMIN.andMAX.

level marks for each coolant reservoir

when each engine is cold.

F18E0NY

1

1. Level between marks when engine is cold

WARNING

Check coolant level with cold en-

gines. Never add coolant in cool-

ing system when engines are hot.

NOTE: The boat is considered level

when it is in water. When boat is on a

trailer, block the wheels and ra

ise the

bow slightly with the trailer jack (if so

equipped) until the bumper rail is level.

Add coolant to have the level between

marks as required. Use a funnel to

avoid spillage. Do not over

fill.

Properly reinstall and tighten filler cap.

______________

119

Loading...

Loading...