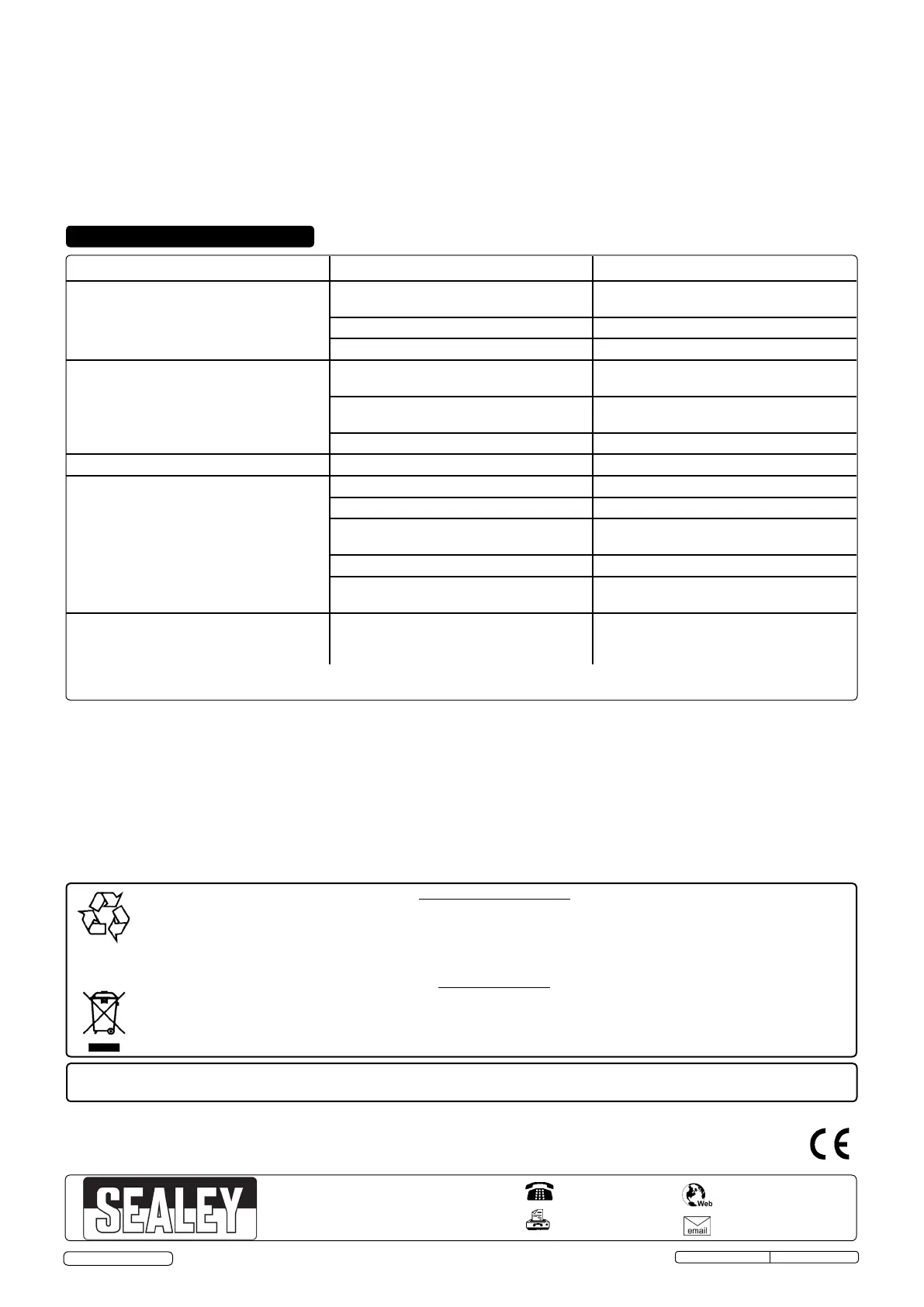

PROBLEM CAUSE SOLUTION

Power source fuse blown Short circuit in either primary or secondary

transformer windings

Return to Sealey dealer for assessment/

repair

Electrode has touched earth clamp Be vigilant to prevent this happening

Wrongly rated fuse Install correct fuse

Welder frequently cuts out The welder is being overworked causing the

thermostatic control to activate

Cut out will automatically reset when welder

has cooled

May also be due to a sticking electrode Cut out will automatically reset when welder

has cooled

Broken fan causing overheating Repair or replace cooling fan

Cooling fan not working properly

Starting capacitance disabled Replace capacitior

Difficulty in striking or maintainig an arc

The electrode is damp Heat it up to 60º - 70º before using

Wrong type of electrode Use correct electrode

Bad connection between earth clamp and

workpiece

Grind connection area and reattach clamp

Regulation screw and nut worn out Replace worn out parts

Partial short circuit in transformer windings Return to Sealey dealer for assessment/

repair

Noise from within case when welding Uneven gap between the moving iron core

and static iron core

Return to Sealey Dealer to have cores

adjusted

140XT.V2, 160XT.V2 Issue: 1 - 16/04/14

9. TROUBLESHOOTING

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

WEEE Regulations

Dispose of this product at the end of its working life in compliance with the EU Directive on

Waste Electrical and Electronic Equipment (WEEE). When the product is no longer required, it must be disposed

of in an environmentally protective way. Contact your local solid waste authority for recycling information.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Original Language Version

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500.

© Jack Sealey Limited

8.9. Earthing of the workpiece. It is important that the workpiece is separately bonded to earth in addition to the welder/cutter return

cable. Where the workpiece is not bonded to earth for electrical safety reasons or because of its size and position, e.g. ship’s hull or

building steelwork, a connection bonding the workpiece to earth may reduce emissions in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece increasing the risk of injury to others or damage to other electrical equipment.

Where necessary, the connection of the workpiece to earth should be made by a direct connection to the workpiece, but in some

countries where direct connection is not permitted, the bonding should be achieved by a suitable capacitance, selected according to

national regulations.

8.10. Screening and shielding. Selective screening and shielding of other cables and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire welding/cutting installation may be considered for special applications.

Loading...

Loading...